A kind of method of catalytic cracking diesel oil production BTX fraction

A technology for catalytic cracking of diesel oil and distillates, which is applied in the treatment of hydrocarbon oil, petroleum industry, hydrotreating process, etc. It can solve the problems of poor selectivity of BTX and achieve the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

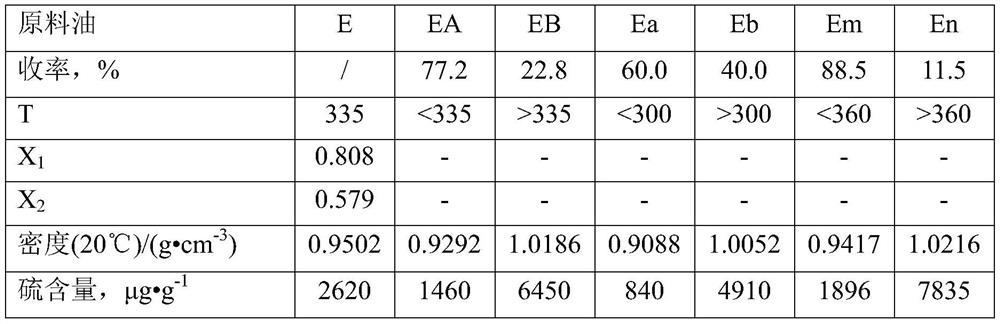

[0052] The raw material oil E is cut into light FCC diesel fraction EA (335°C) at the cut point of 335°C. EA enters the low-pressure hydrocracking unit, and contacts and reacts with hydrorefining catalyst A and hydrocracking catalyst B respectively. EB enters the hydrotreating unit, and the resulting liquid phase stream enters the catalytic cracking unit for reaction. The reaction product of the low-pressure hydrocracking unit and the reaction product of the catalytic cracking unit are fractionated to obtain gas, BTX-rich fraction and diesel fraction. The reaction conditions are shown in Table 2, and the product properties are shown in Table 3.

[0053] It can be seen from Table 1 that after the catalytic cracking diesel oil E is cut into EA and EB, the nitrogen content in EA is greatly reduced, and the content of nitrogen compounds that are difficult to react with carbazoles is also greatly reduced. Nitrogen removal provides favorable conditions. At the same time, the tota...

Embodiment 2

[0056] The raw material oil E is cut into light FCC diesel fraction EA (335°C) at the cut point of 335°C. EA enters the low-pressure hydrocracking unit, and contacts and reacts with hydrorefining catalyst A and hydrocracking catalyst B respectively. EB enters the hydrotreating unit, and the resulting liquid phase stream enters the catalytic cracking unit for reaction. The reaction product of the low-pressure hydrocracking unit and the reaction product of the catalytic cracking unit are fractionated to obtain gas, BTX-rich fraction and diesel fraction. The reaction conditions are shown in Table 2, and the product properties are shown in Table 3.

[0057] It can be seen from Table 3 that after optimizing the reaction conditions, the yield of the BTX-rich fraction can be further increased to 68.5%, and the yield of BTX can be increased to 31.3%.

Embodiment 3

[0059] The raw material oil E is cut into light FCC diesel fraction EA (335°C) at the cut point of 335°C. EA enters the low-pressure hydrocracking unit, and contacts and reacts with hydrorefining catalyst A and hydrocracking catalyst B respectively. EB enters the hydrotreating unit, and the resulting liquid phase stream enters the catalytic cracking unit for reaction. The reaction product of the low-pressure hydrocracking unit and the reaction product of the catalytic cracking unit are fractionated to obtain gas, BTX-rich fraction and diesel fraction. The diesel fraction obtained by fractional distillation is recycled to the low-pressure hydrocracking unit. The reaction conditions are shown in Table 2, and the product properties are shown in Table 3.

[0060] As can be seen from Table 3, the yield of the BTX-rich fraction reaches 87.2%, and the yield of BTX reaches 38.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com