Built-in multi-piece type wet brake

A wet brake, multi-plate technology, used in mechanical drive clutches, clutches, couplings, etc., can solve the problem of uneven distribution of the compression force of the coil spring, larger axial size of the brake housing, and unstable brake braking. and other problems to achieve the effect of avoiding excessive friction temperature, strong braking and recovery effect, and short return time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

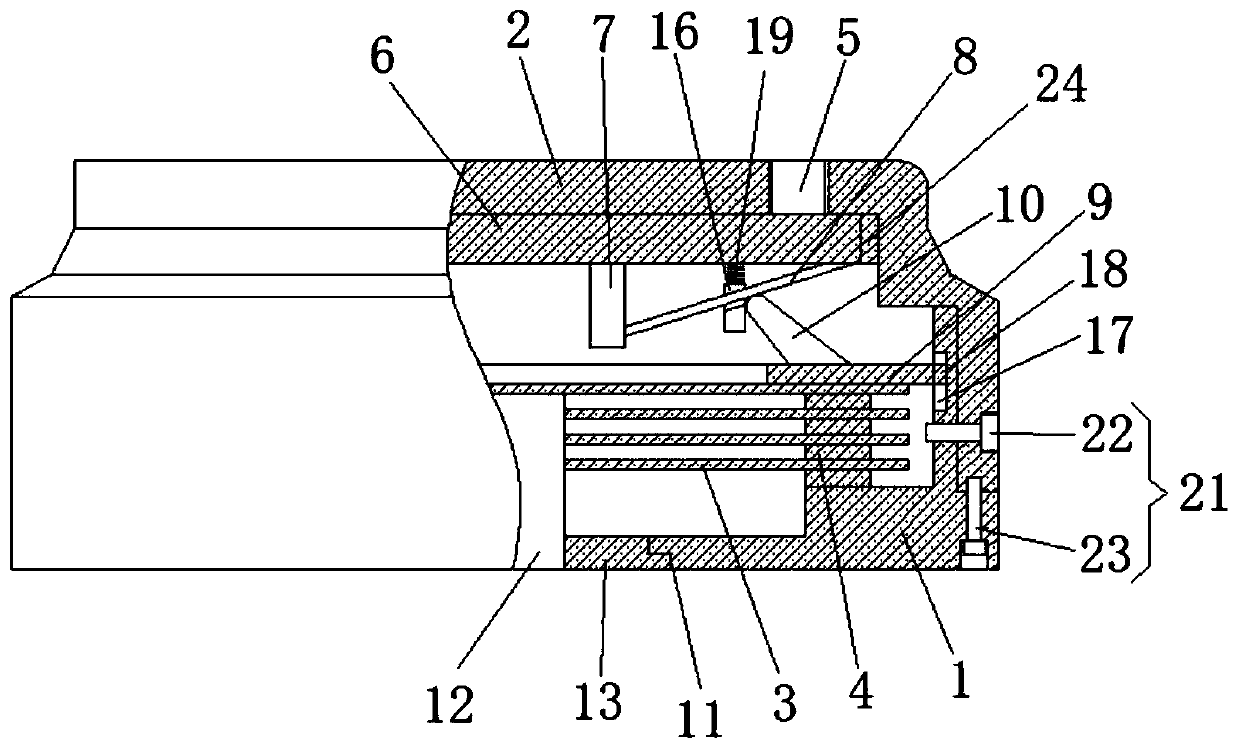

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

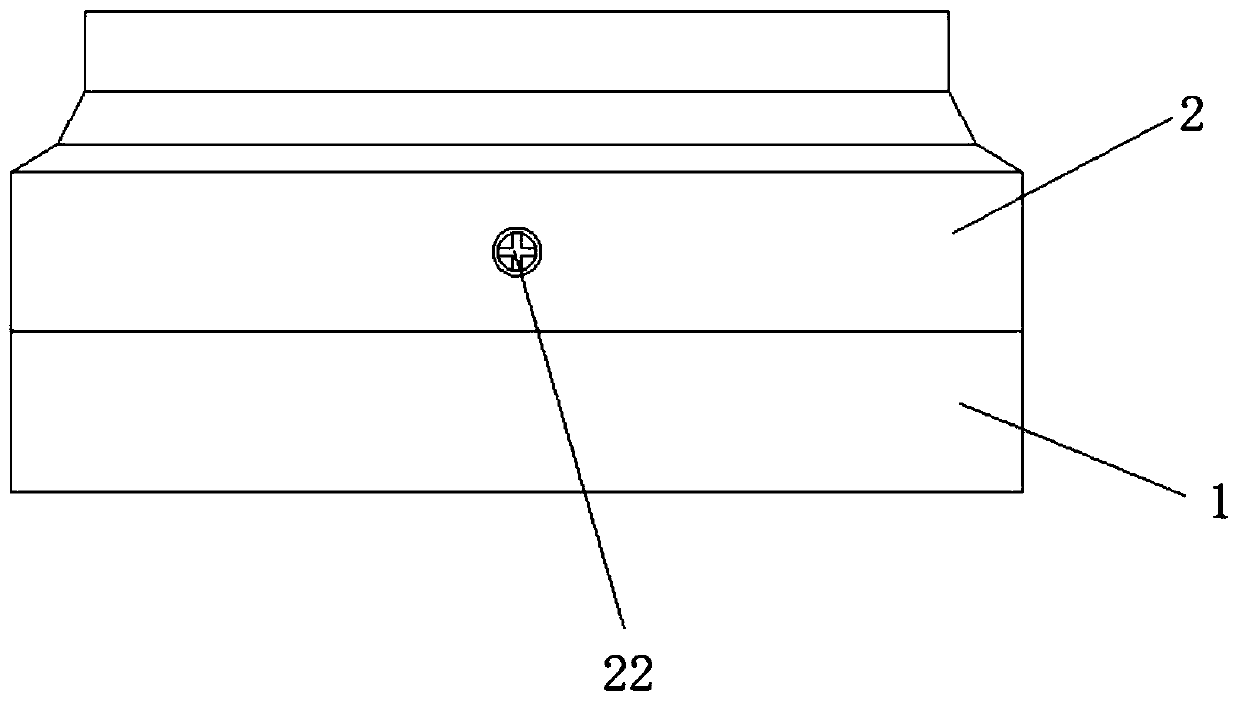

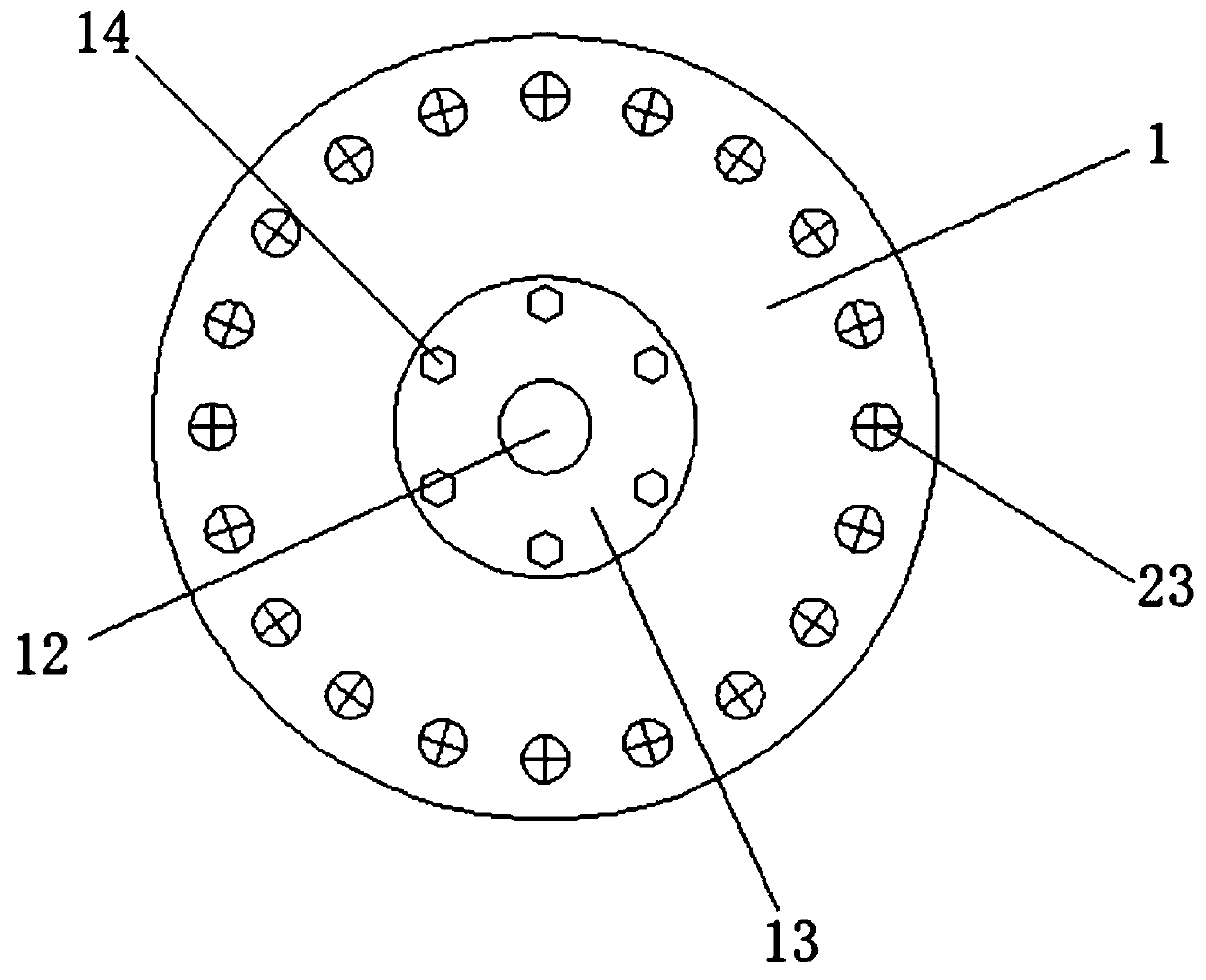

[0024] refer to Figure 1-4 , a built-in multi-plate wet brake, including a housing 1 and a sealing plate 2, the housing 1 and the sealing plate 2 are fixedly connected by bolts 21, the bolts 21 include oil drain bolts 22 and countersunk bolts 23, the oil drain bolts 22 runs through the sealing plate 2 and the housing 1 in turn horizontally, and the countersunk head bolt 23 vertically penetrates the housing 1 and is fixedly connected with the sealing plate 2. By setting the oil drain bolt 22, it is more convenient and quick to replace the friction oil without disassembling it completely The addition and discharge of friction oil can be realized, which reduces labor i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com