Rotatable material distributing valve device for coal mine gangue paste body filling and operation method

A technology of rotating cloth and paste filling, applied in valve device, valve operation/release device, valve details, etc., to achieve the effect of simple and labor-saving operation, reduced consumption, convenient disassembly and maintenance, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

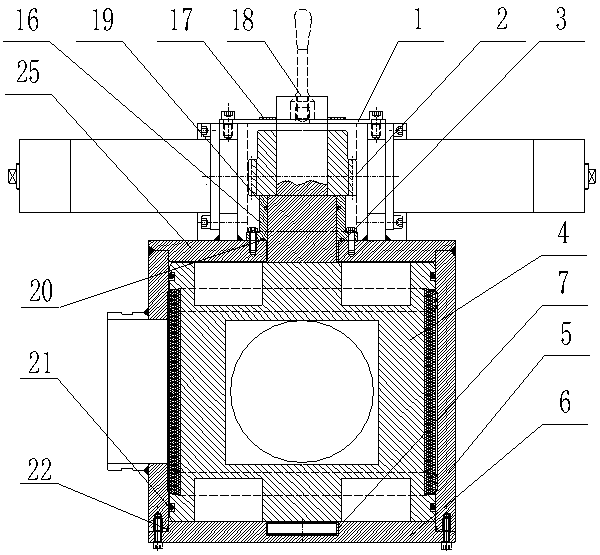

[0054] Embodiment 1: as figure 1 , The rotating shaft and the valve body adopt multiple seals to ensure that there will be no leakage under high pressure. The rotating shaft and gear parts are connected by a square shaft to increase the strength. The gear and rack transmission is relatively safe and reliable.

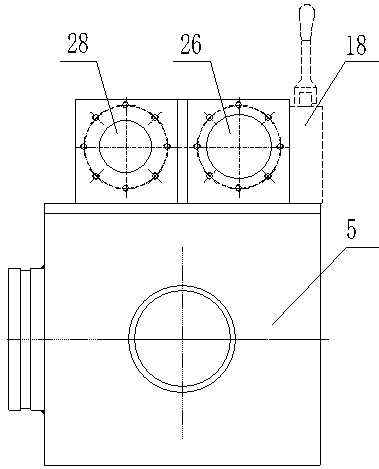

[0055] Figure 4 and Figure 5 The structure of the rotation switch is shown, and the communication between the A feed port and the C discharge port, and the communication between the A feed port and the B discharge port can be realized through a 90° rotation.

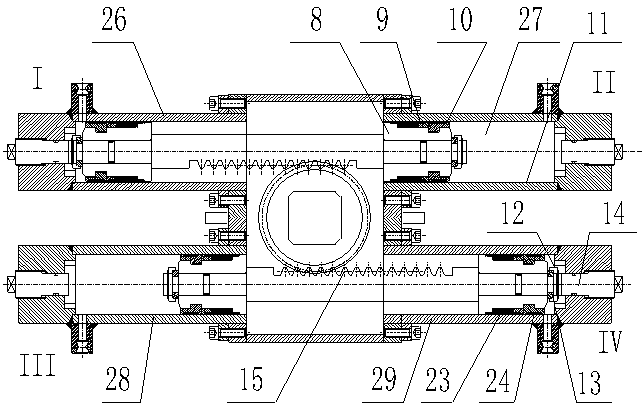

[0056] image 3 It shows the transmission of the gear and the rack. The rack is driven by the cylinder to drive the gear and the rotating shaft to rotate, so as to realize the channel switching. The No. 1 hydraulic cylinder and the No. 4 hydraulic cylinder are in one group, and the No. 2 hydraulic cylinder and the No. 3 hydraulic cylinder are one The group realizes the synchronous promotion of the rack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com