Ultrahigh pressure rupture disk safety release device

A technology of safety relief and ultra-high pressure, applied in the direction of safety valves, valve devices, engine components, etc., can solve any problems that have not been raised yet, and achieve the benefits of popularization, avoiding dangerous conditions, good sealing and anti-pumping performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the present invention will be further described, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

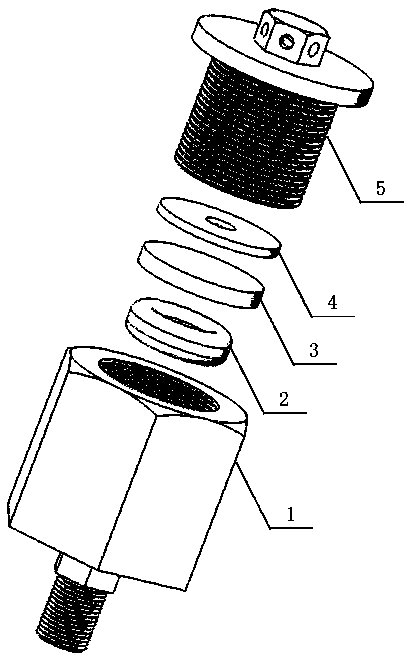

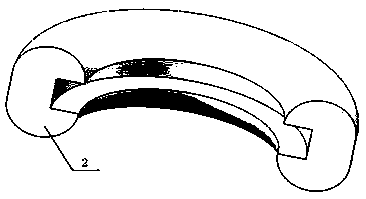

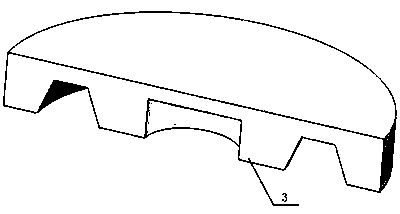

[0023] see figure 1 , The split-type ultra-high pressure rupture disc safety release device of the present invention includes a lower holder, a self-tightening lens seal ring, an ultra-high pressure rupture disc, a pressure ring, and an upper holder. The upper holder, lower holder and pressure ring are made of 35CrMo steel, the ultra-high pressure rupture disc is made of 316L stainless steel, and the self-tightening lens sealing ring is made of No. 10 steel. The lower holder is connected to the ultra-high pressure vessel through threads. In order to ensure that the ultra-high pressure rupture disc is connected with the gas phase spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com