Method for determining microsphere plugging performance

A technology of plugging performance and microspheres, which is applied in the direction of measuring devices, suspension and porous material analysis, instruments, etc., can solve the problems of low efficiency and time-consuming, etc., and achieve simple and convenient simulation, long experiment cycle, and reduce experimental consumables cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

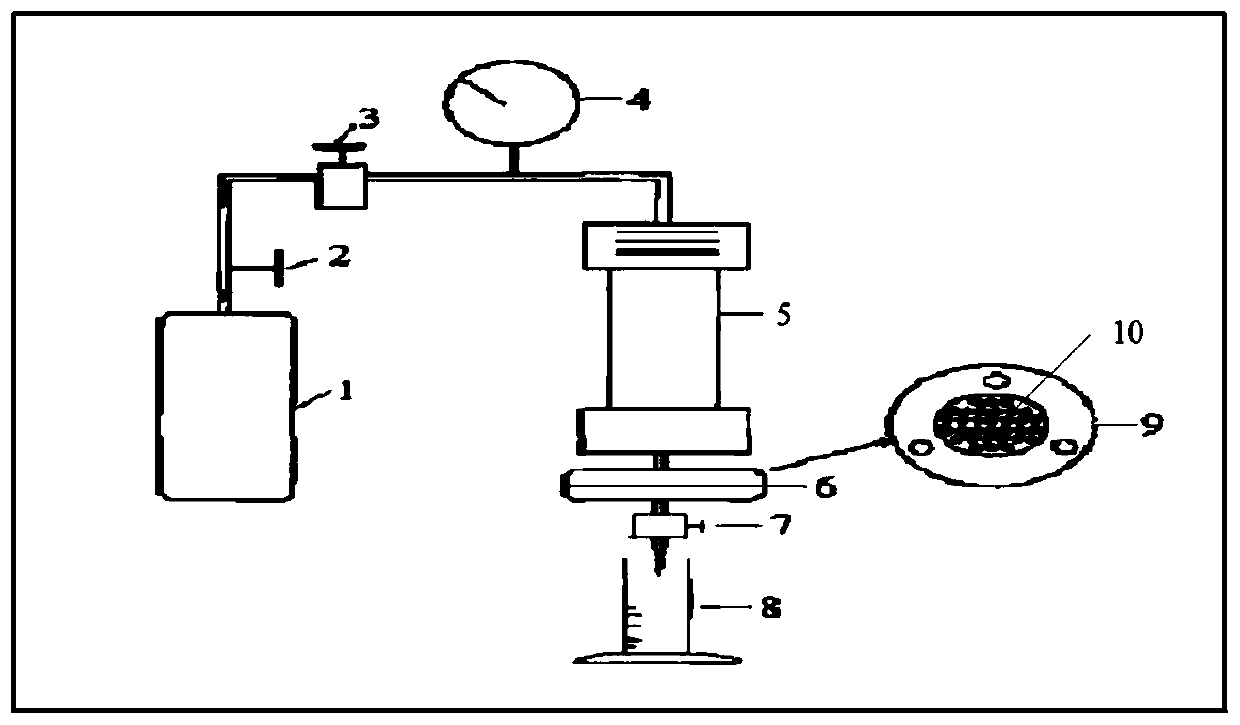

Method used

Image

Examples

Embodiment 1

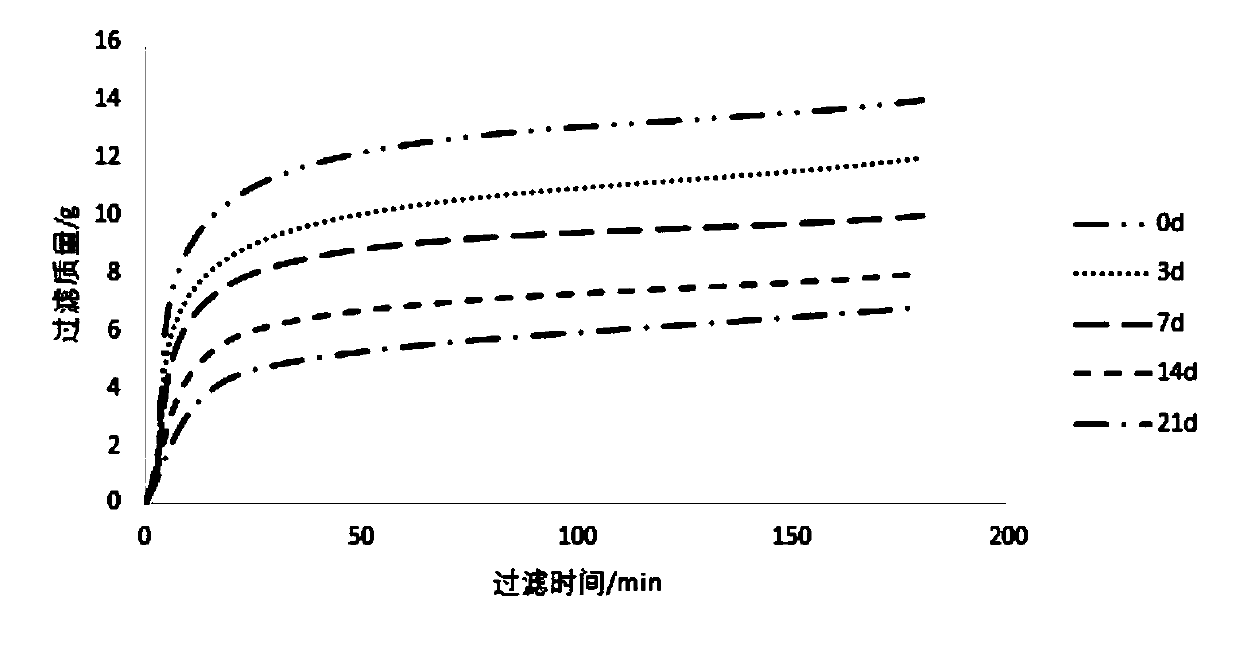

[0036] Experimental parameters: polymer microsphere type II (purchased from Gu'an Guokan Petroleum Technology Co., Ltd.) concentration 3000 mg / L, filter membrane pore size 600 mesh (converted to exactly 23 μm, consistent with reservoir conditions), filter membrane Density is 10 6 / cm 2 , the filtration time is 180min, and the microspheres with the hydration time of 0d, 3d, 7d, 14d and 21d are respectively filtered, and the obtained image 3 .

Embodiment 2

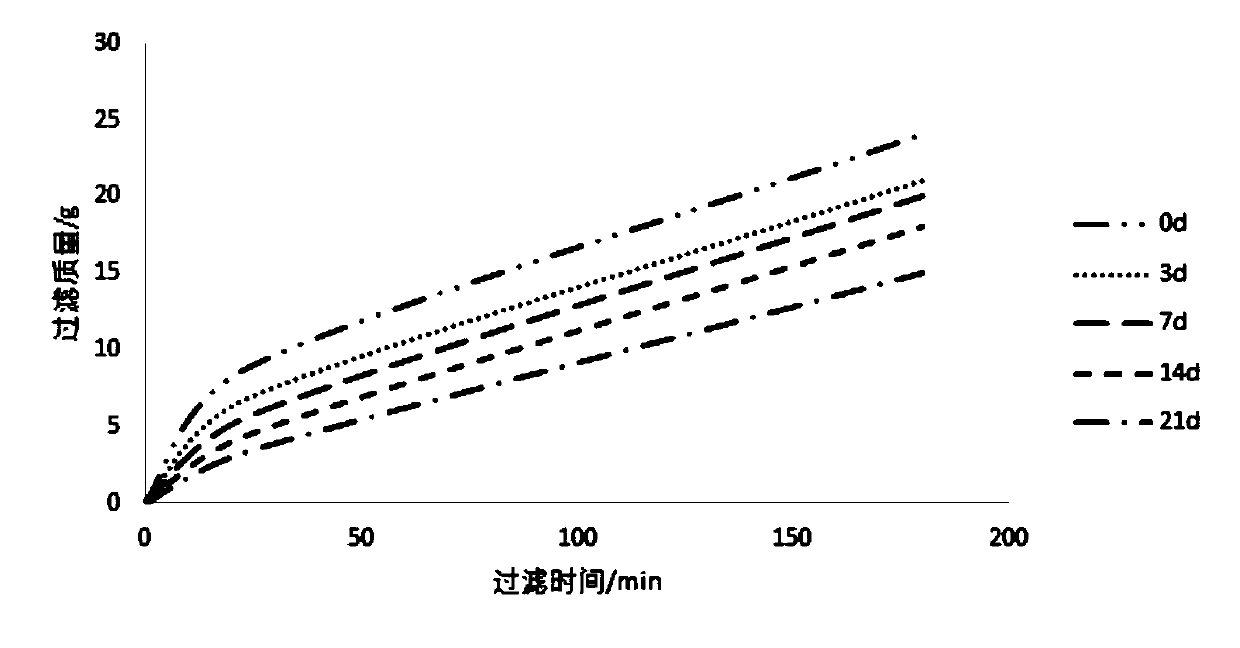

[0038] Polymer microsphere type I (purchased from Gu'an Guokan Petroleum Technology Co., Ltd.), select the same experimental conditions as polymer microsphere type I, and the experimental results are as follows figure 2 .

[0039] Table 1 The particle size parameters of polymer microspheres I and II

[0040] Types of Particle size (primary particle size) Particle size (hydration 20d) Polymer Microsphere I 300-1500nm 11μm-19μm Polymer Microsphere II 10~200nm 5μm-9μm

[0041] From figure 2 and image 3 It can be seen that at the same time, image 3 The quality of filtered polymer microsphere solution was significantly higher than figure 2 . The quality of the solution filtered out per minute, the more the quality of the filter membrane, the worse the blocking ability. The mass of liquid filtered out by polymer microsphere type II under the same hydration days and time is obviously greater than that of polymer microsphere I (it can als...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com