Integrated camera assembly for magnetic powder inspection fluorescence imaging of small special-shaped part

A magnetic particle inspection and fluorescence imaging technology, applied in fluorescence/phosphorescence, material magnetic variables, material excitation analysis, etc., can solve the problems of online magnetic particle inspection, such as difficult operation, conflict of use, difficult ultraviolet light irradiation, etc., to achieve high-efficiency magnetic particle inspection fluorescence Imaging detection, improve detection effect, avoid detection blind spot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

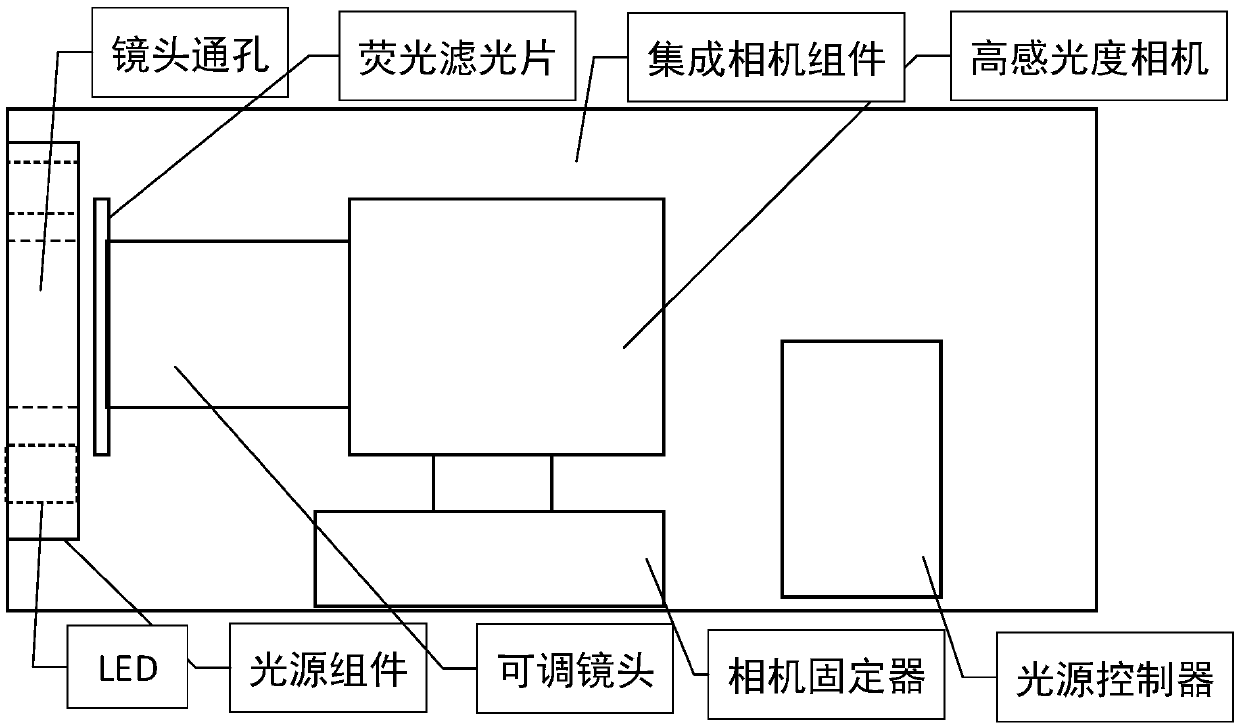

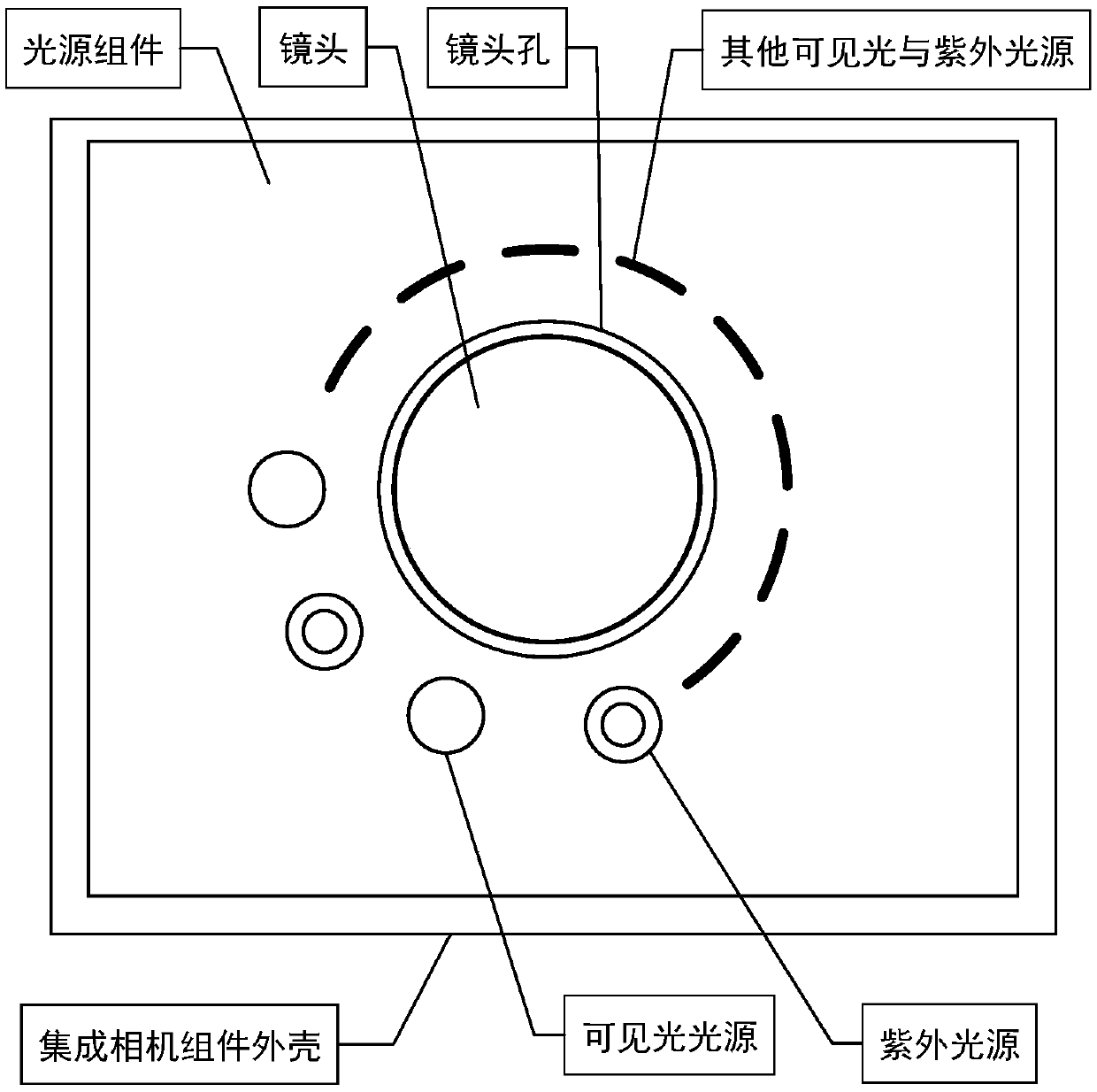

[0032] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] The detailed features and advantages of the present invention are described in detail below in the specific embodiments, the content of which is sufficient to enable any person skilled in the art to understand the technical content of the present invention and implement it accordingly, and according to the specification, claims and drawings disclosed in this specification , those skilled in the art can easily understand the related objects and advantages of the present invention.

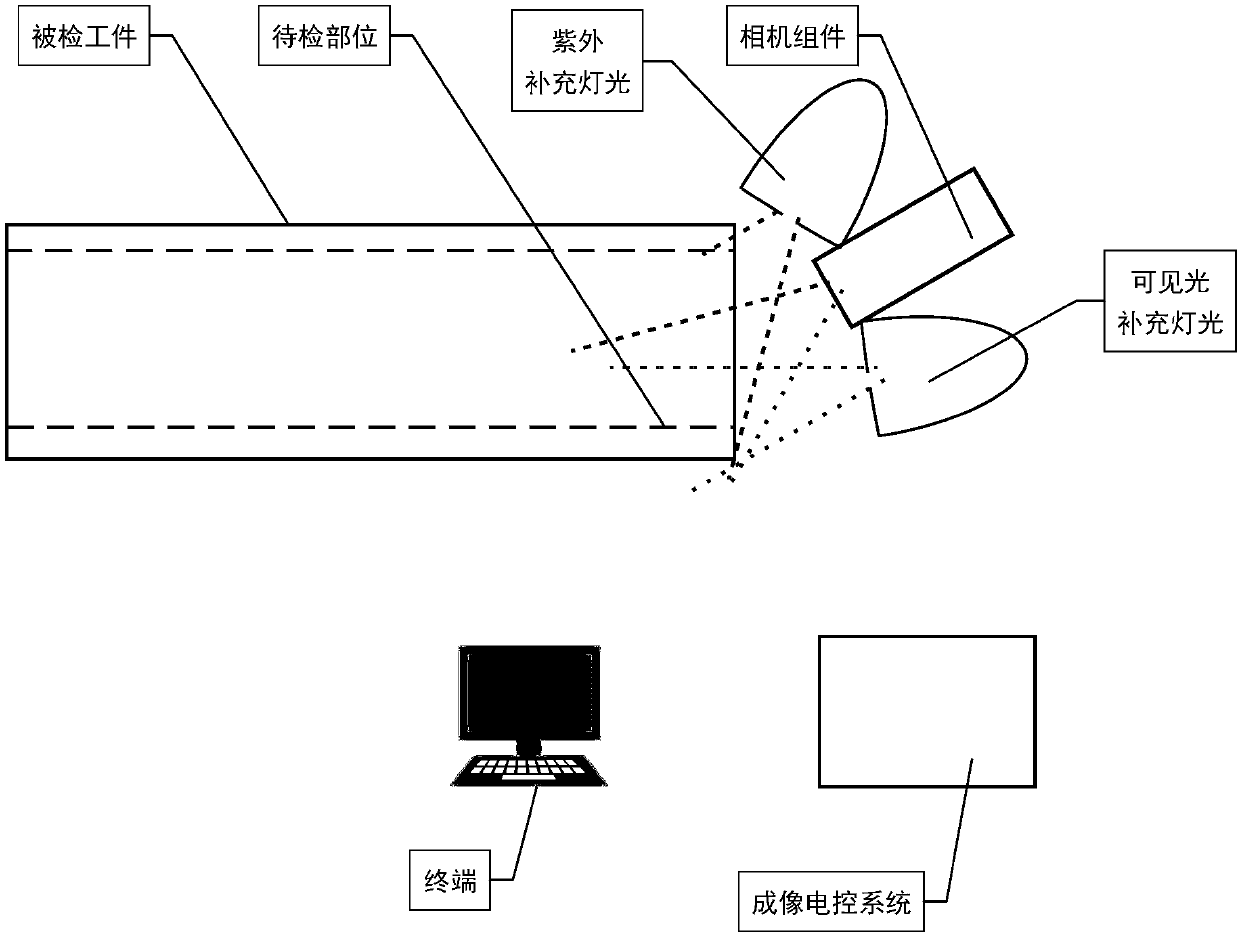

[0034] The basic principle of magnetic particle flaw detection fluorescence imaging detection is as follows:

[0035] The measured magnetic object is magnetized under the action of an external magnetic field, and at the same time it is sprayed with magnetic suspension and irradiated with ultraviolet light. If there is a defect on the surface or shallow sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com