A kind of ultra-low temperature cable

A technology of ultra-low temperature and cables, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of large, unsatisfactory, inability of cables to withstand ultra-low temperature, low resistance change rate, etc., achieve low density, improve anti-electromagnetic interference, and increase electrical conductivity performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

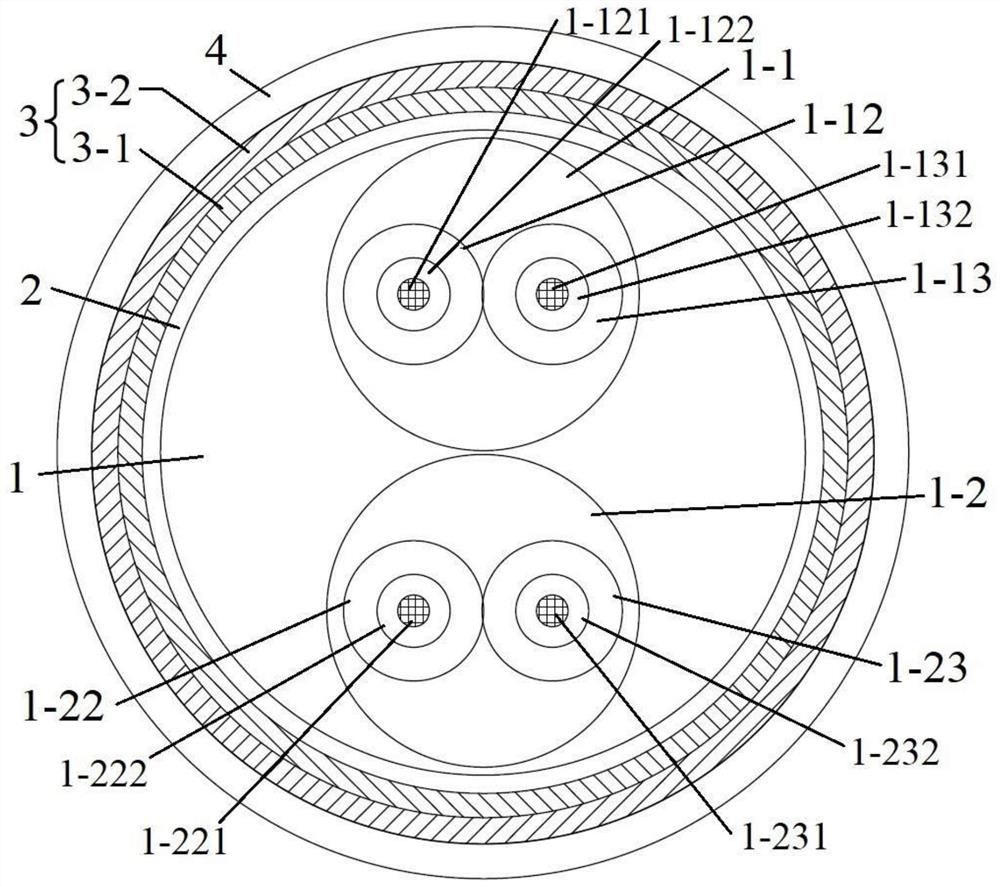

[0038] Such as figure 1 As shown, the ultra-low temperature cable provided by this embodiment includes an insulating core layer 1, a braid layer 2, a wrapping layer 3, and a sheath layer 4 sequentially from the inside to the outside.

[0039] The central layer cable core 1 is composed of two pairs of cable core unit groups 1-1 and cable core unit group 1-2, and the cable core unit group 1-1 consists of an insulated outer conductor 1-12 and an insulated outer conductor 1-13 Formed in pairs, the insulated outer conductor 1-12 includes a conductor 1-121 and an ethylene-tetrafluoroethylene copolymer insulation layer 1-122 on its outer layer, and the insulated outer conductor 1-13 includes a conductor 1-131 and The ethylene-tetrafluoroethylene copolymer insulating layer 1-132 in its outer layer; the ethylene-tetrafluoroethylene copolymer insulating layer 1-122 and the 1-132 ethylene-tetrafluoroethylene copolymer insulating layer are respectively extruded by extrusion process Outsi...

Embodiment 2

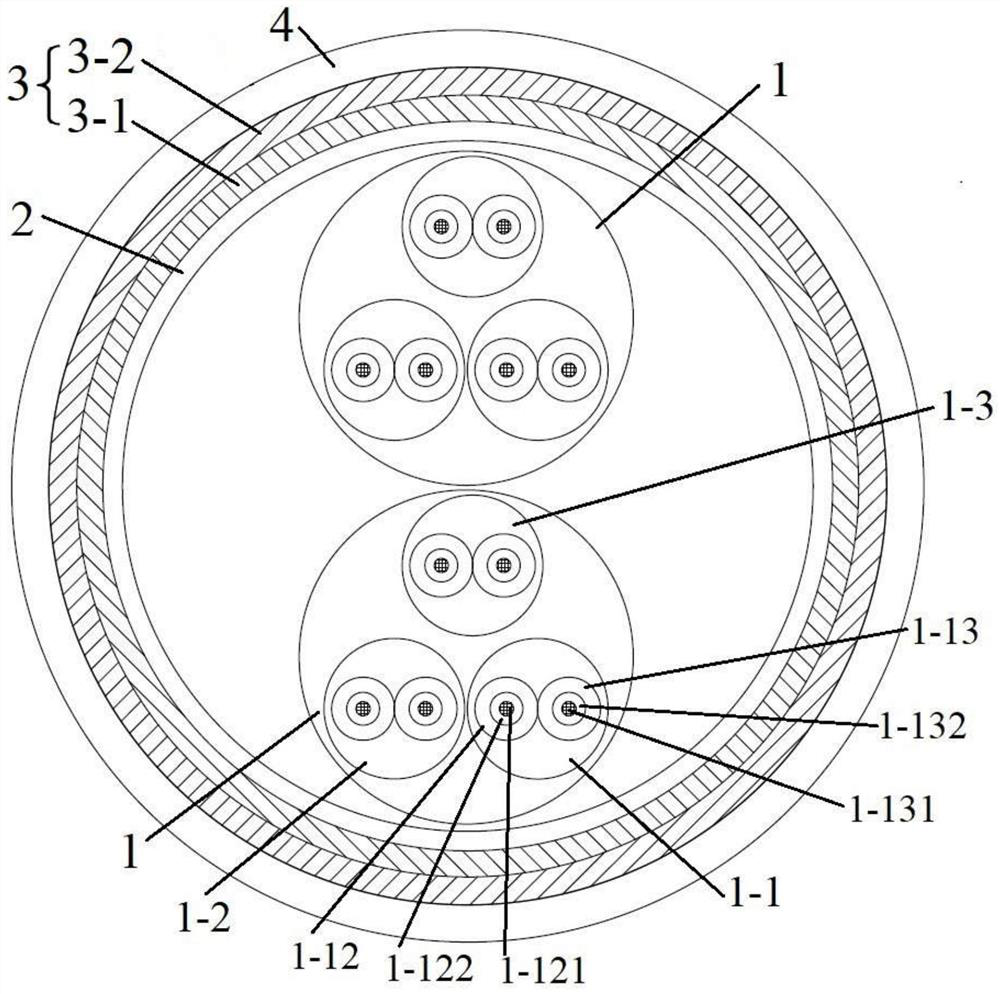

[0055] Such as figure 2 As shown, it is a kind of ultra-low temperature cable provided by this embodiment, which sequentially includes two insulated central layer cable cores 1, braided layer 2, wrapping layer 3, and sheath layer (4) from the inside to the outside; the central layer cable core 1 It is composed of three pairs of cable core unit groups - cable core unit group 1-1, cable core unit group 1-2 and cable core unit group 1-3. Cable core unit group 1-1 consists of two insulated outer conductors - insulated outer conductors 1-12 and the insulated outer conductor 1-13 are twisted to form, the insulated outer conductor 1-12 includes a conductor 1-121 and an ethylene-tetrafluoroethylene copolymer insulating layer 1-122 on its outer layer, and the insulated outer conductor 1 -13 includes a conductor 1-131 and an ethylene-tetrafluoroethylene copolymer insulating layer 1-132 on its outer layer; ethylene-tetrafluoroethylene copolymer insulating layer 1-122 and 1-132 ethylene-...

Embodiment 3

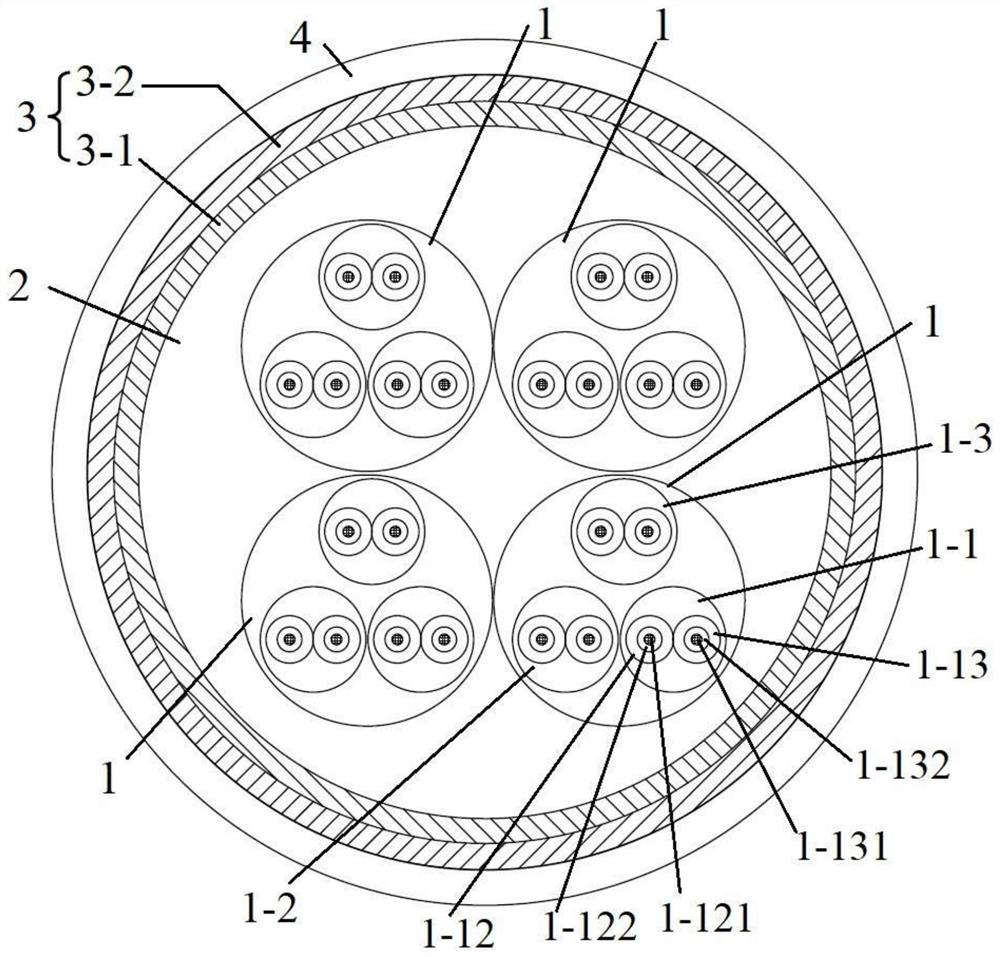

[0069] Such as image 3 As shown, it is an ultra-low temperature cable provided in this embodiment, which sequentially includes four insulating core layer cores 1, braiding layer 2, wrapping layer 3, and sheath layer 4 from inside to outside;

[0070] The central layer cable core 1 is composed of three pairs of cable core unit groups—cable core unit group 1-1, cable core unit group 1-2 and cable core unit group 1-3. The cable core unit group 1-1 is composed of two insulating outsourcing Conductor—the insulated outer conductor 1-12 and the insulated outer conductor 1-13 are twisted to form, and the insulated outer conductor 1-12 includes a conductor 1-121 and an ethylene-tetrafluoroethylene copolymer insulating layer 1-122 on its outer layer , the insulated outer conductor 1-13 includes a conductor 1-131 and an ethylene-tetrafluoroethylene copolymer insulation layer 1-132 on its outer layer; ethylene-tetrafluoroethylene copolymer insulation layer 1-122 and 1-132 ethylene - The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com