Feeding mechanism of automatic cooking machine and automatic cooking machine

A feeding mechanism and cooking machine technology, applied in the field of kitchen supplies, can solve the problems of reducing the service life of automatic cooking equipment, pouring out raw materials, poor stability, etc., and achieve the effects of improving transportation reliability, reducing shaking, and reducing the probability of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

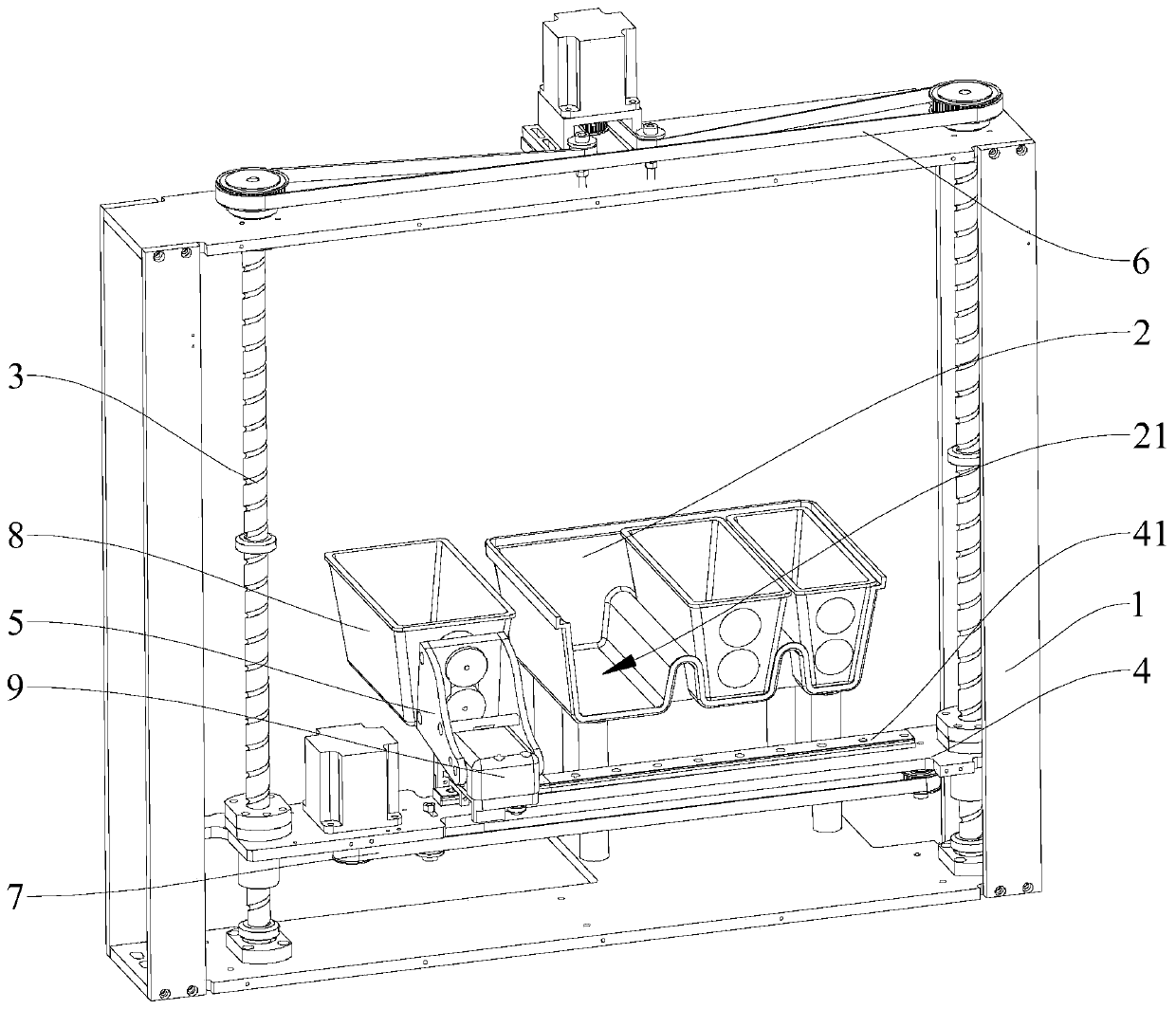

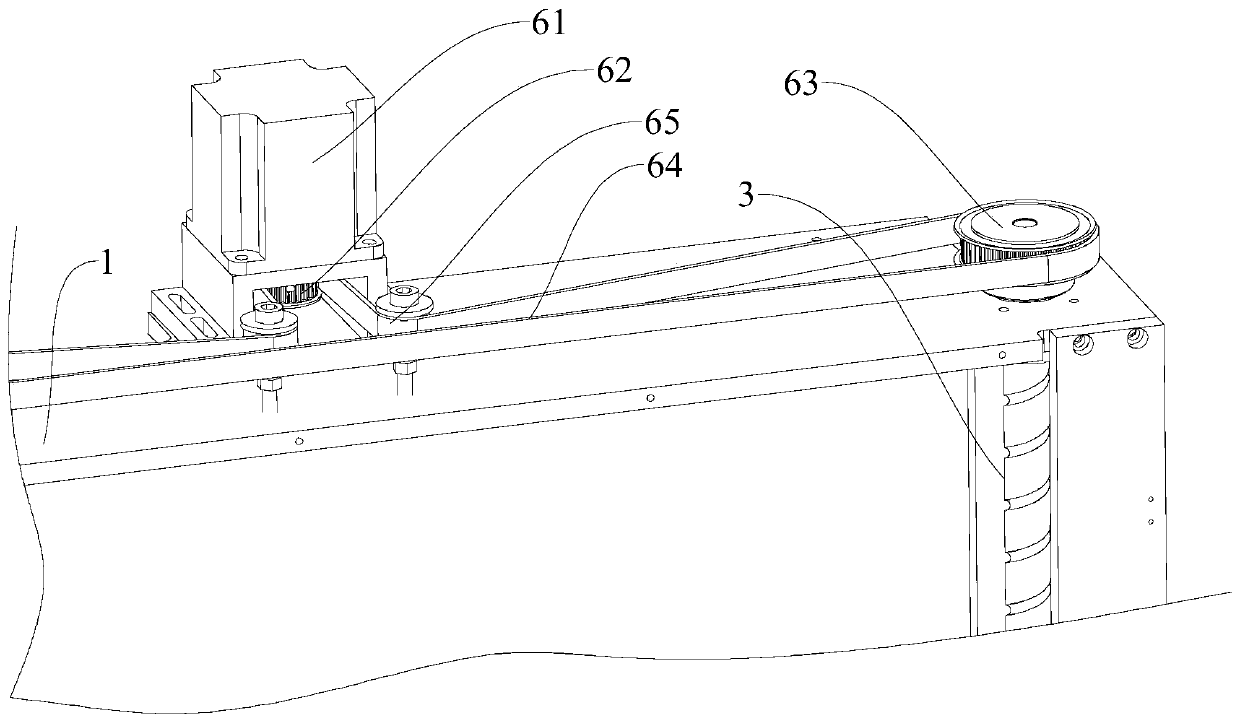

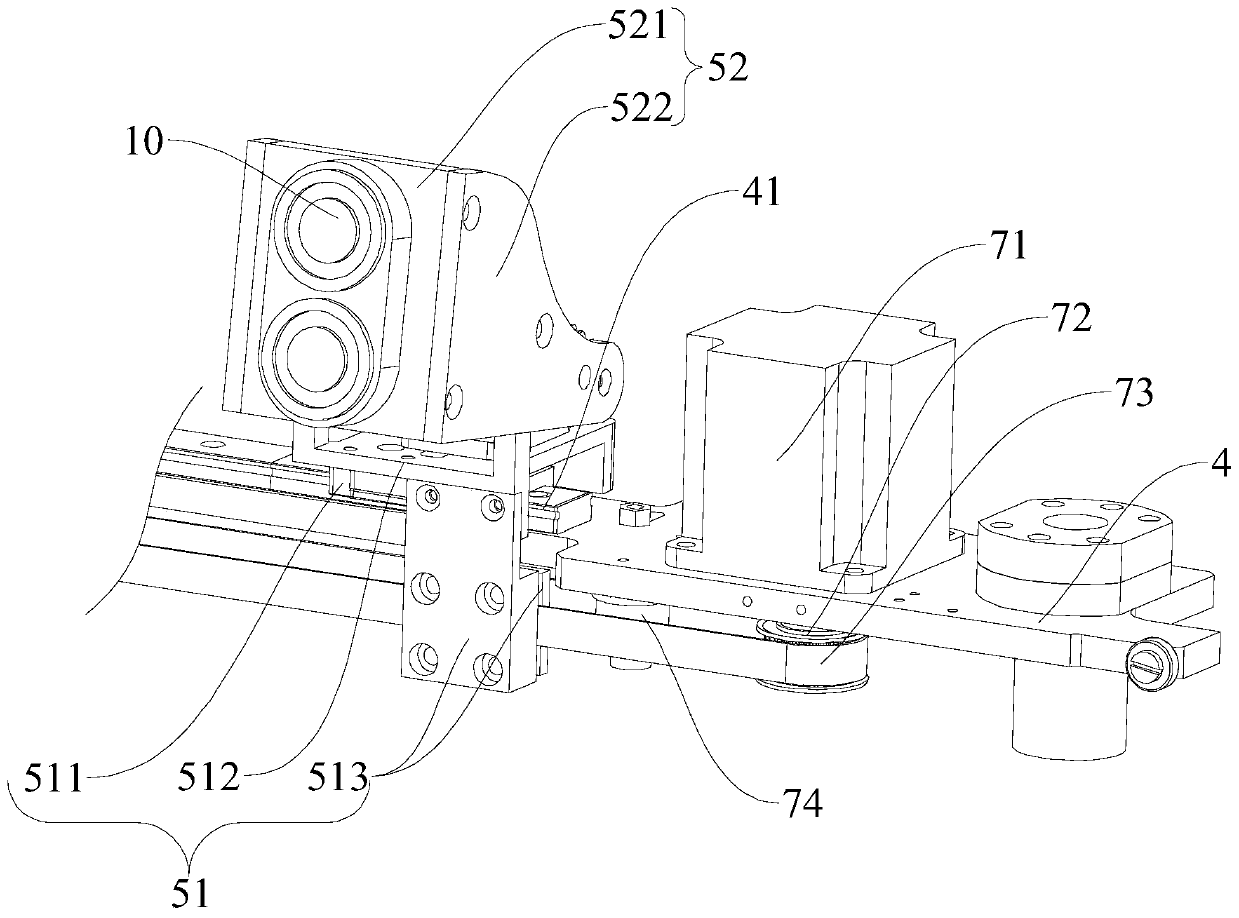

[0058] Refer below Figure 1-Figure 3 Describe the feeding mechanism of the automatic cooking machine of a specific embodiment of the present invention.

[0059]The feeding mechanism of the automatic cooking machine of this embodiment includes a frame 1, a material storage rack 2, two lead screws 3, a fitting 4, a retrieving assembly 5, a first driving assembly 6, a second driving assembly 7 and a material box 8 , the storage rack 2 is connected on the frame 1, and the storage rack 2 is provided with a plurality of storage tanks 21, and each storage tank 21 is equipped with a material box 8, and the height and height of the plurality of storage tanks 21 are The lengths are the same, but the widths of the plurality of storage tanks 21 are different. The width and length of the cartridge 8 gradually increase towards its opening. The axial ends of each lead screw 3 are respectively connected to two opposite side plates of the frame 1 , and the connecting parts 4 are connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com