A vertical reflow furnace

A reflow oven and light eye technology, applied in welding equipment, manufacturing tools, transportation and packaging, etc., can solve problems such as board drop, PCB board transportation not in place, PCB board jamming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

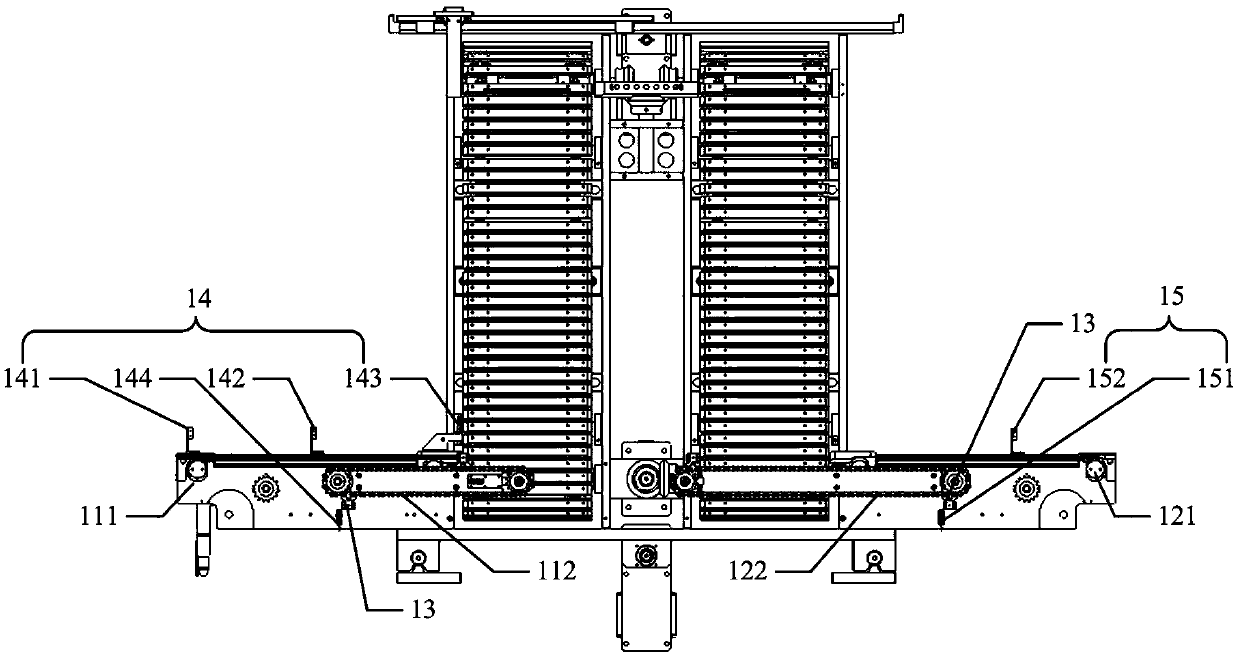

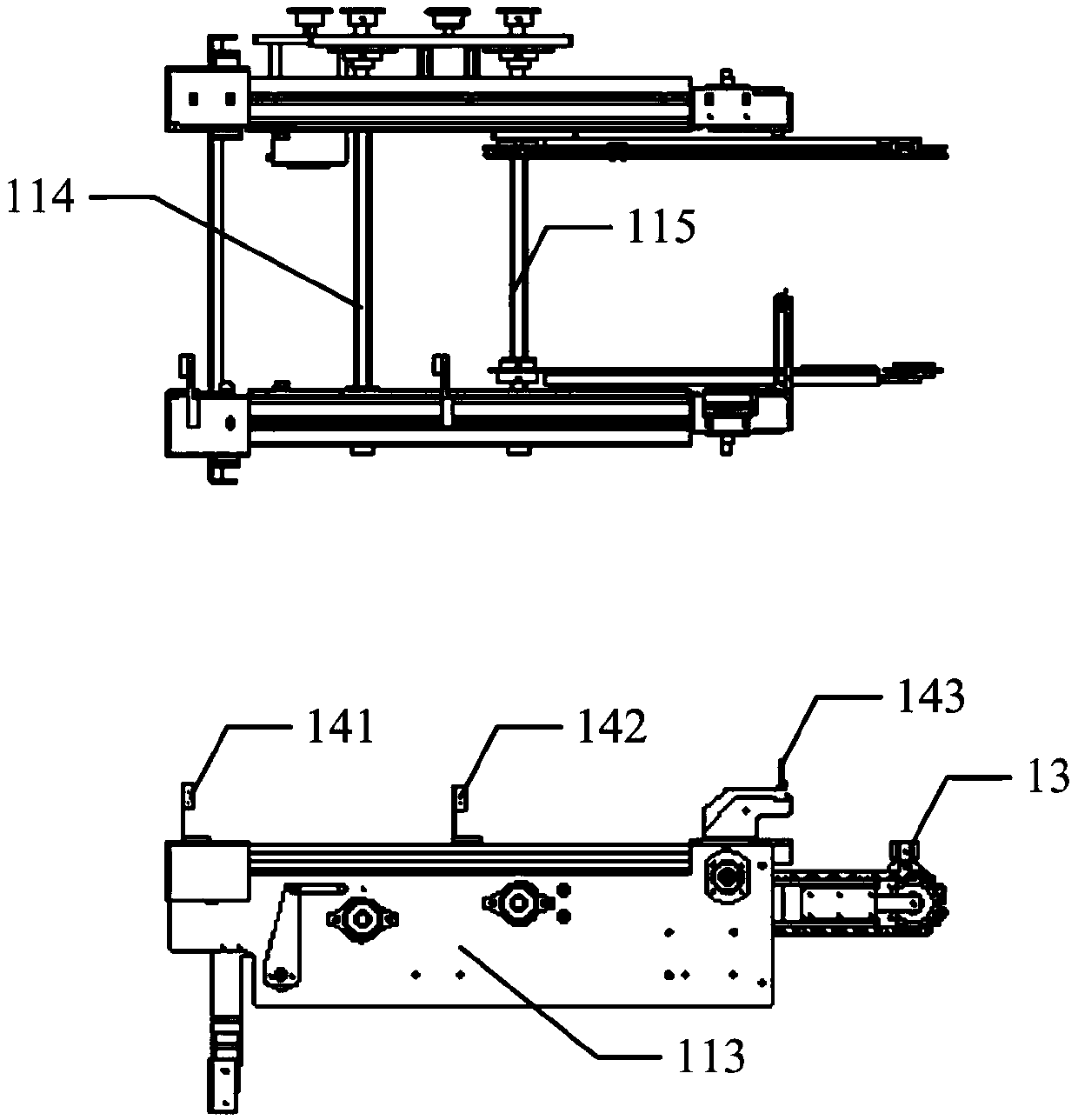

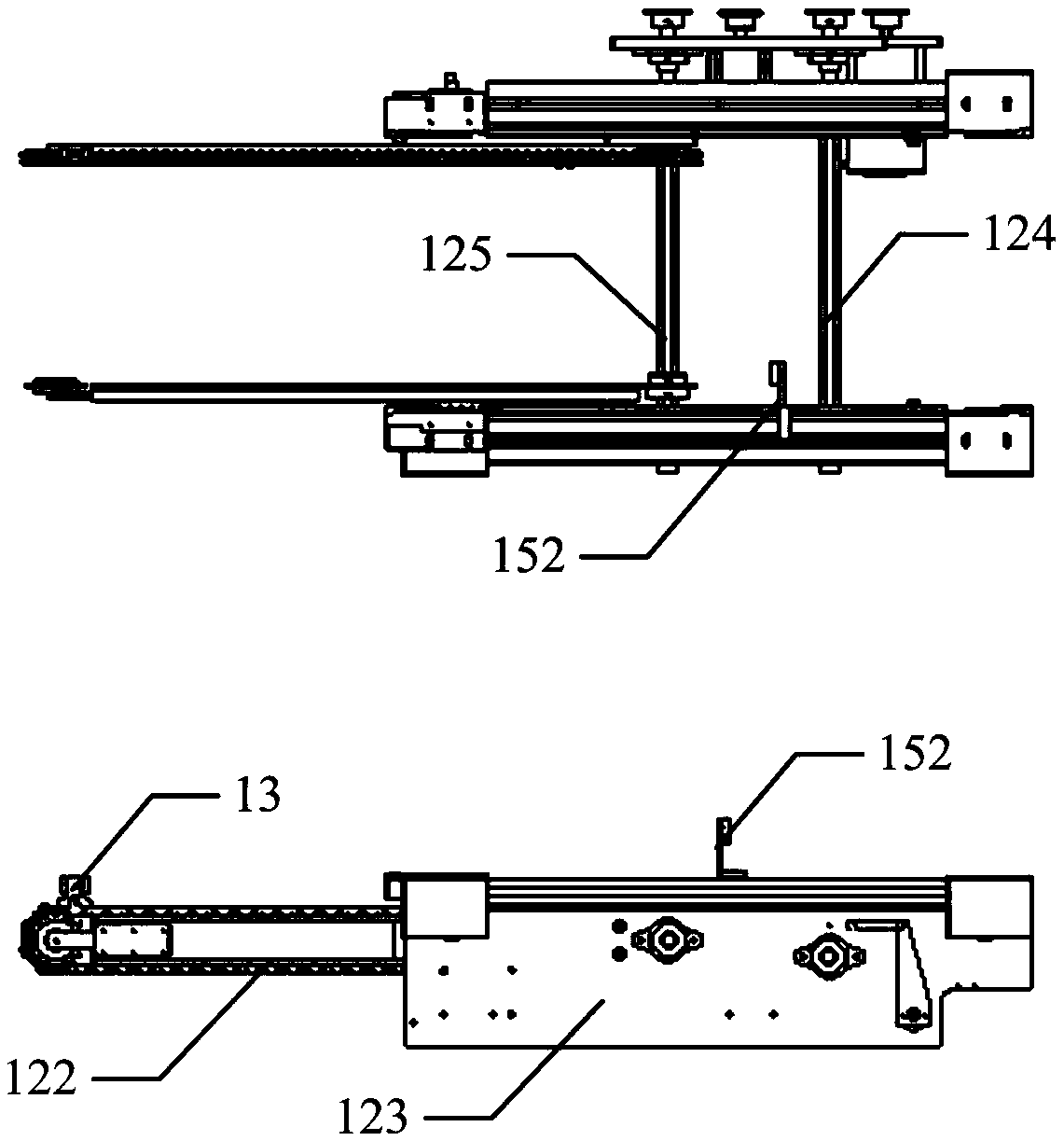

[0049] The embodiment of the present invention provides a vertical reflow furnace. By connecting the entrance and exit connection mechanism with the vertical transportation channel of the vertical reflow furnace, it can effectively prevent the PCB from staying and jamming when it enters and exits the vertical transportation channel at the connection point, and reduce the production cost. The scrap rate is high, the production efficiency of the product is improved, and the product connection is smoother.

[0050] In order to enable those skilled in the art to better understand the solutions of the present invention, the following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments are only It is an embodiment of a part of the present invention, but not all embodiments. Based on the embodiments of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com