Rice huller for stripping rice husks off by applying differential gear

A differential gear and grain hulling machine technology, applied in the field of grain hulling machines, can solve problems such as unclean peeling of rice husks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

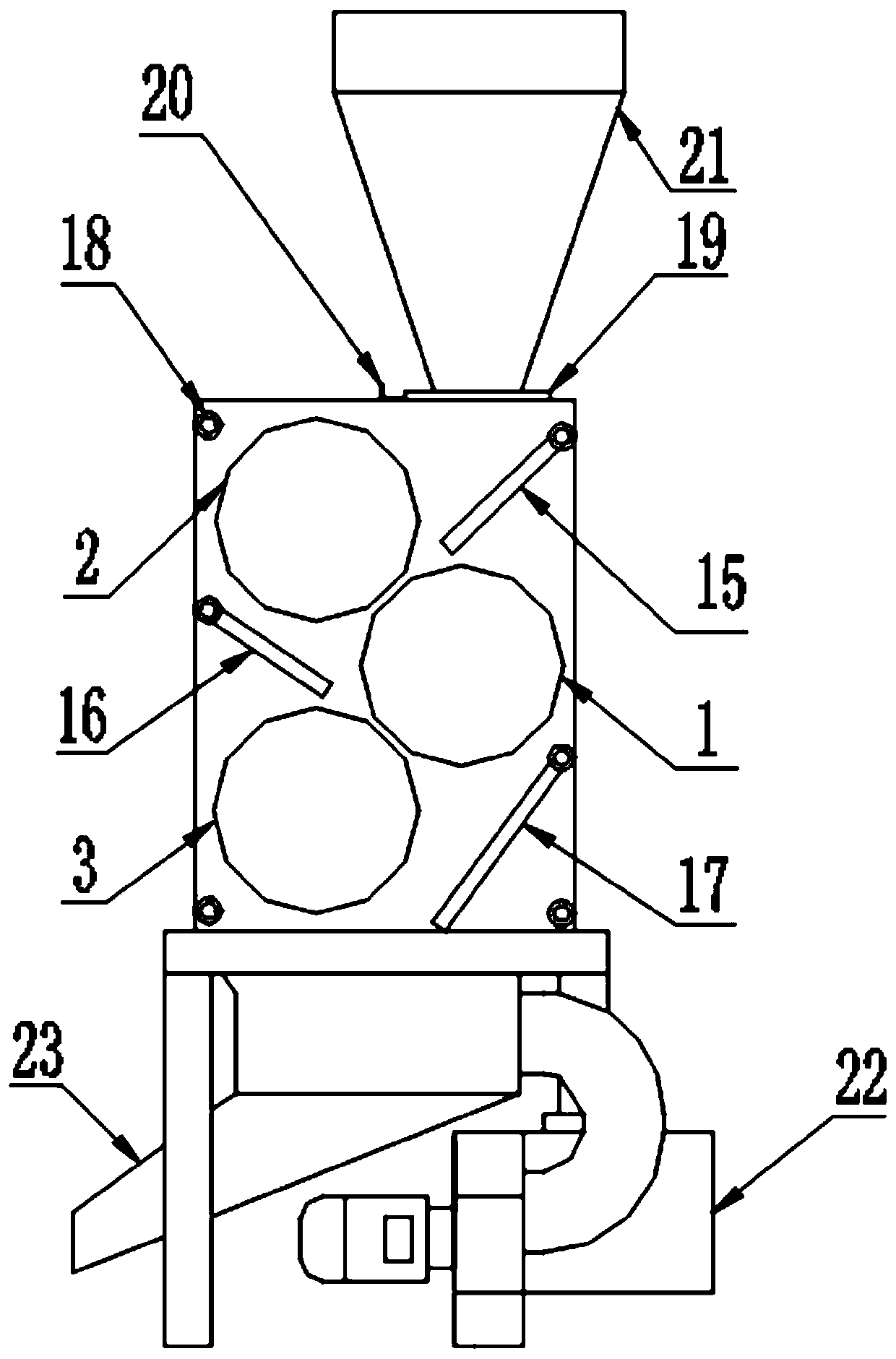

[0026] Such as figure 1 As shown, the present invention uses a differential gear to peel off the rice husk, including a first rubber roller 1, and a second rubber roller 2 is arranged on one side of the first rubber roller 1, and the second rubber roller 2 is located on the first rubber roller. Above the rubber roller 1, the second rubber roller 2 is parallel to the first rubber roller 1. There is a first gap for rice to pass between the second rubber roller 2 and the first rubber roller 1. One side of the first rubber roller 1 is provided with The third rubber roller 3, the third rubber roller 3 is coaxial with the second rubber roller 2, the third rubber roller 3 is located below the first rubber roller 1, the third rubber roller 3 is parallel to the first rubber roller 1, the first rubber roller 1 and the third rubber roller 3 are provided with a second gap for rice to pass through. The rice passes through the first gap and then the second gap. The second gap is smaller tha...

Embodiment 2

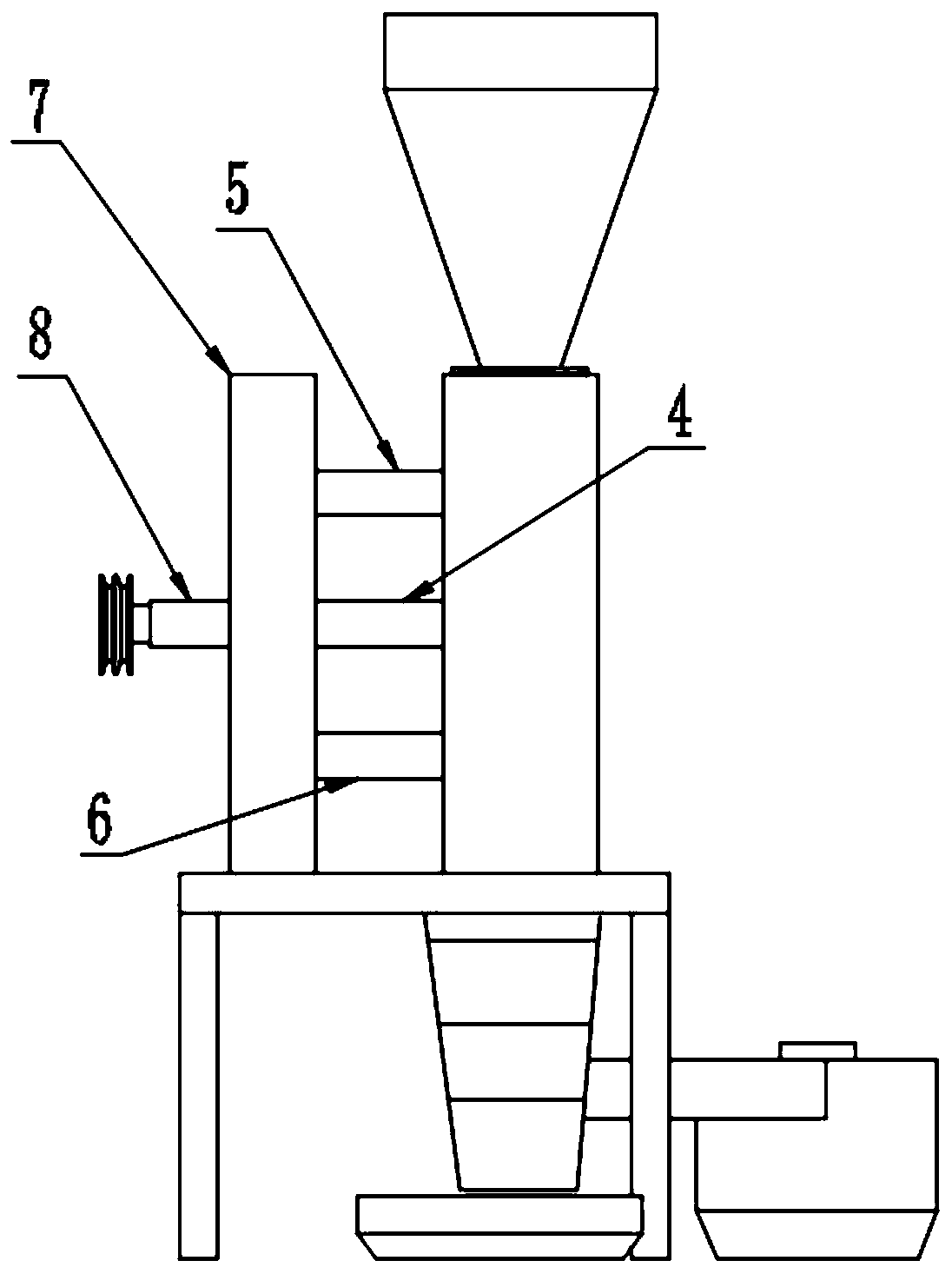

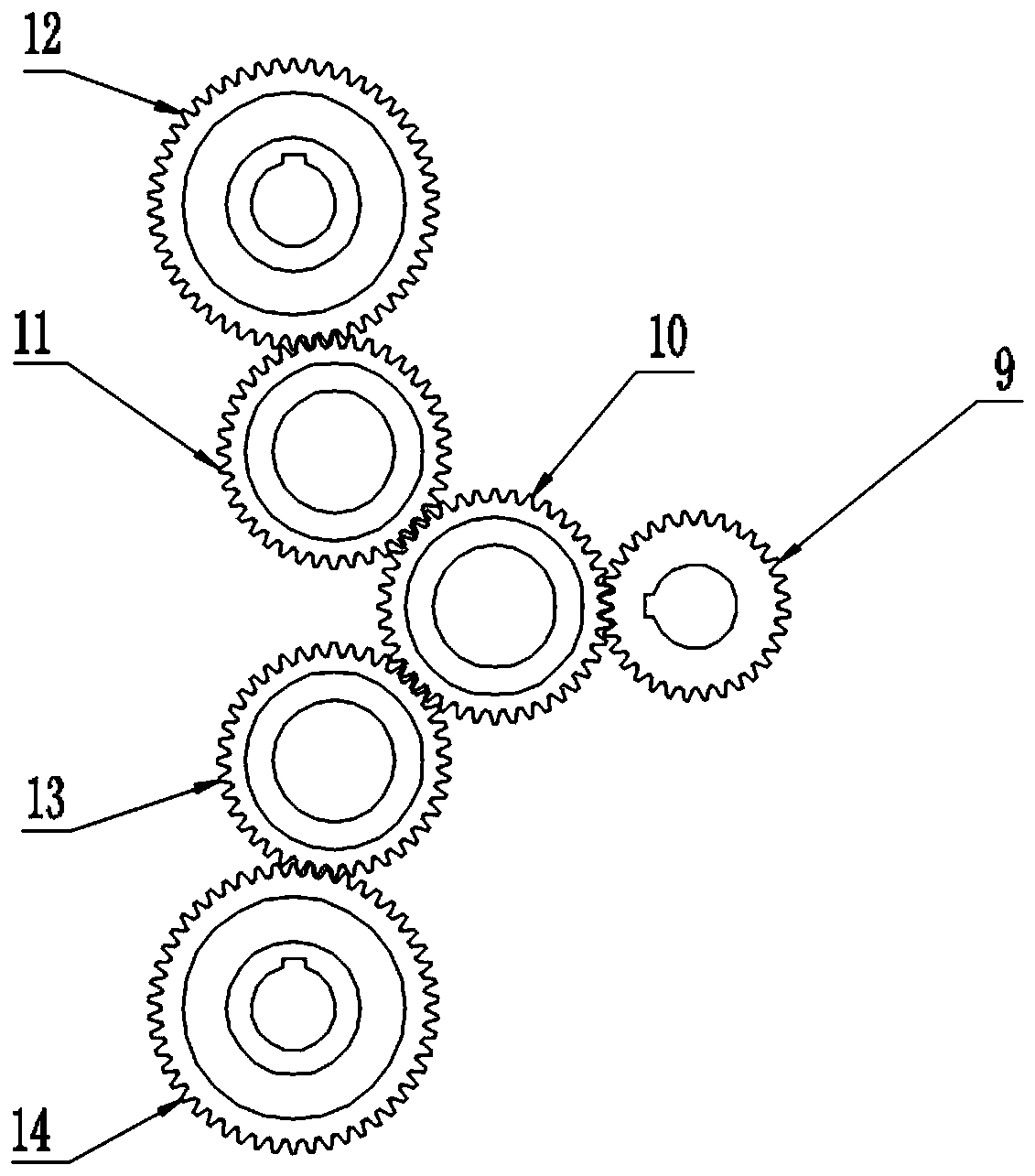

[0029] Based on Example 1, such as Figure 1-3 As shown, the present invention uses a differential gear to peel off rice husks, the first rubber roller 1 is provided with a first transmission shaft 4, the first transmission shaft 4 is connected and fixed with the first rubber roller 1, and the second The rubber roller 2 is provided with a second transmission shaft 5, the second transmission shaft 5 is connected and fixed with the second rubber roller 2, the third rubber roller 3 is provided with a third transmission shaft 6, the third rubber roller 3 and the third transmission shaft 6 is connected and fixed, the other end of the first transmission shaft 4 is provided with a first gear 9, the first transmission shaft 4 and the first gear 9 are connected by a square key, the other end of the second transmission shaft 5 is provided with a second gear 12, and the second transmission The shaft 5 and the second gear 12 are connected by a square key, the other end of the third transm...

Embodiment 3

[0034] Based on Example 1, such as Figure 1-2As shown, the present invention uses a differential gear to peel off the rice husk, the first rubber roller 1, the second rubber roller 2, and the third rubber roller 3 are located in the hulling box 24, and the hulling box 24 is rectangular The hulling box 24 is provided with a plurality of fixed rods 18, and the fixing rods 18 are located on the side wall of the hulling box 24. The first baffle plate 15, the second baffle plate 16, and the third baffle plate are also arranged in the hulling box 24. Baffle 17, the first baffle 15 is located between the first rubber roller 1 and the second rubber roller 2, the second baffle 16 is located between the second rubber roller 2 and the third rubber roller 3, and the third baffle 17 is located Between the first rubber roller 1 and the third rubber roller 3, the hulling box 24 is provided with a connecting plate 19, and the connecting plate 19 is provided with a passage for rice to pass th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com