Dust removal system and dust removal method for electrical screen cabinet

A technology for electrical screen cabinets and dust removal systems, applied to chemical instruments and methods, cleaning methods using gas flow, and dust removal, etc., can solve the problems of difficult dust removal for electrical screen cabinets, achieve good practical value, reduce dust pollution, and design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

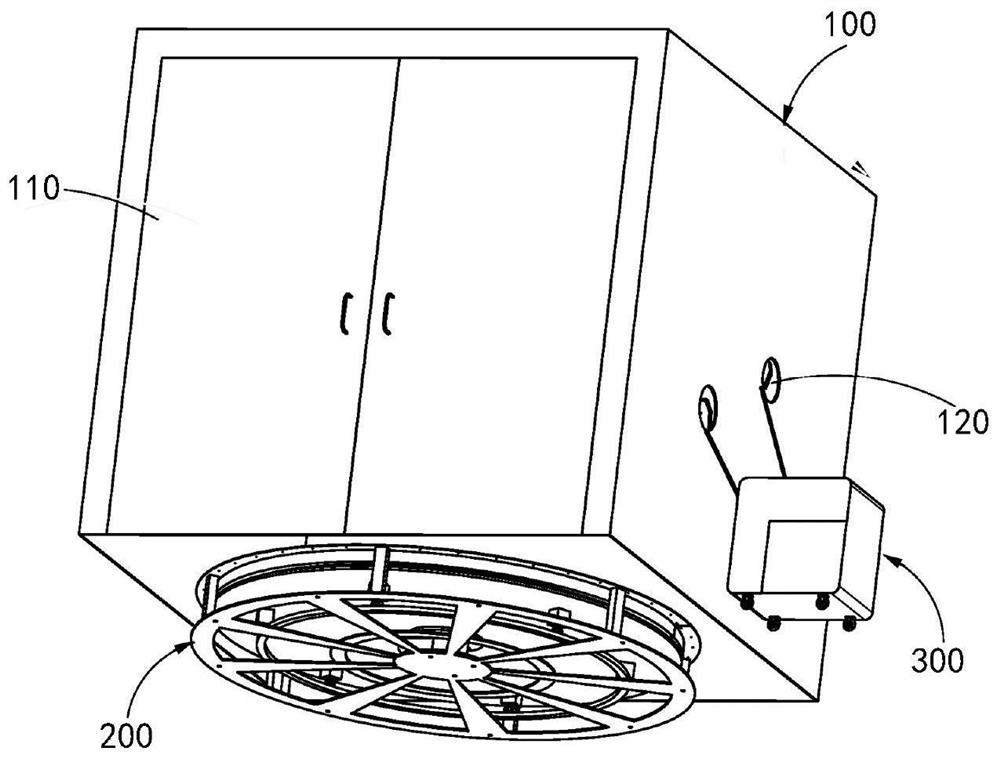

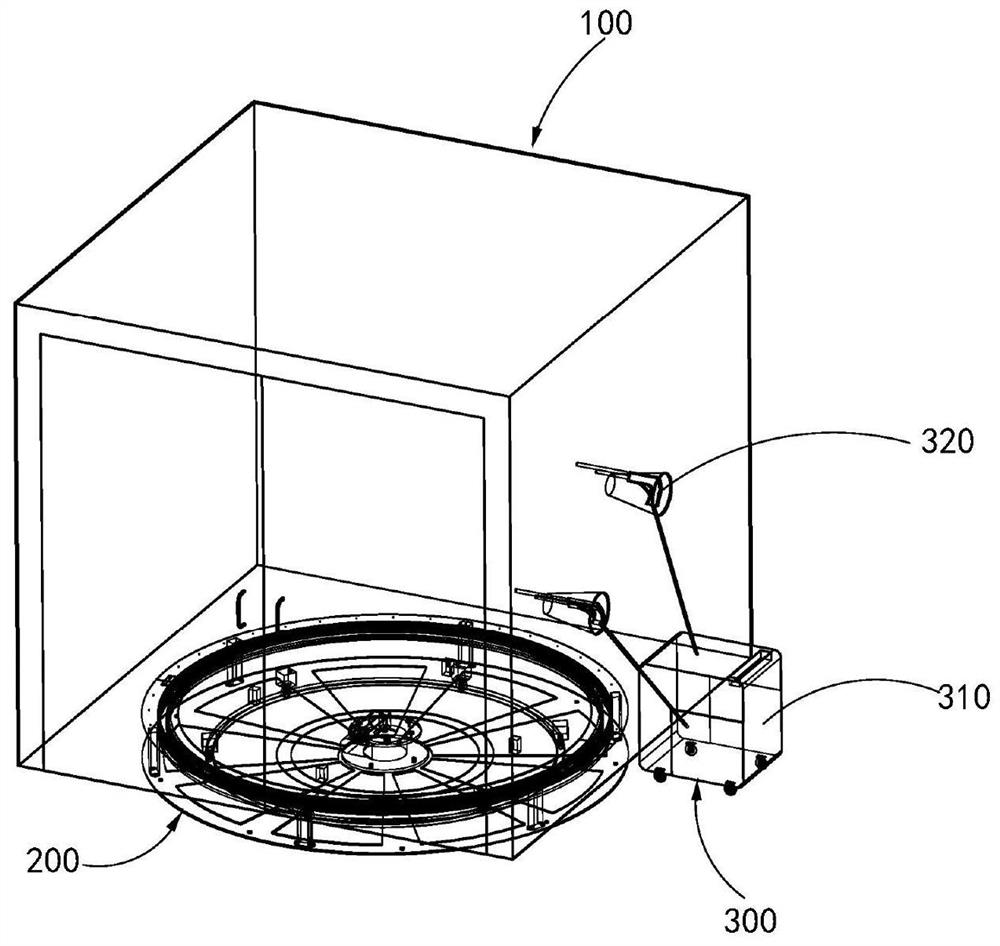

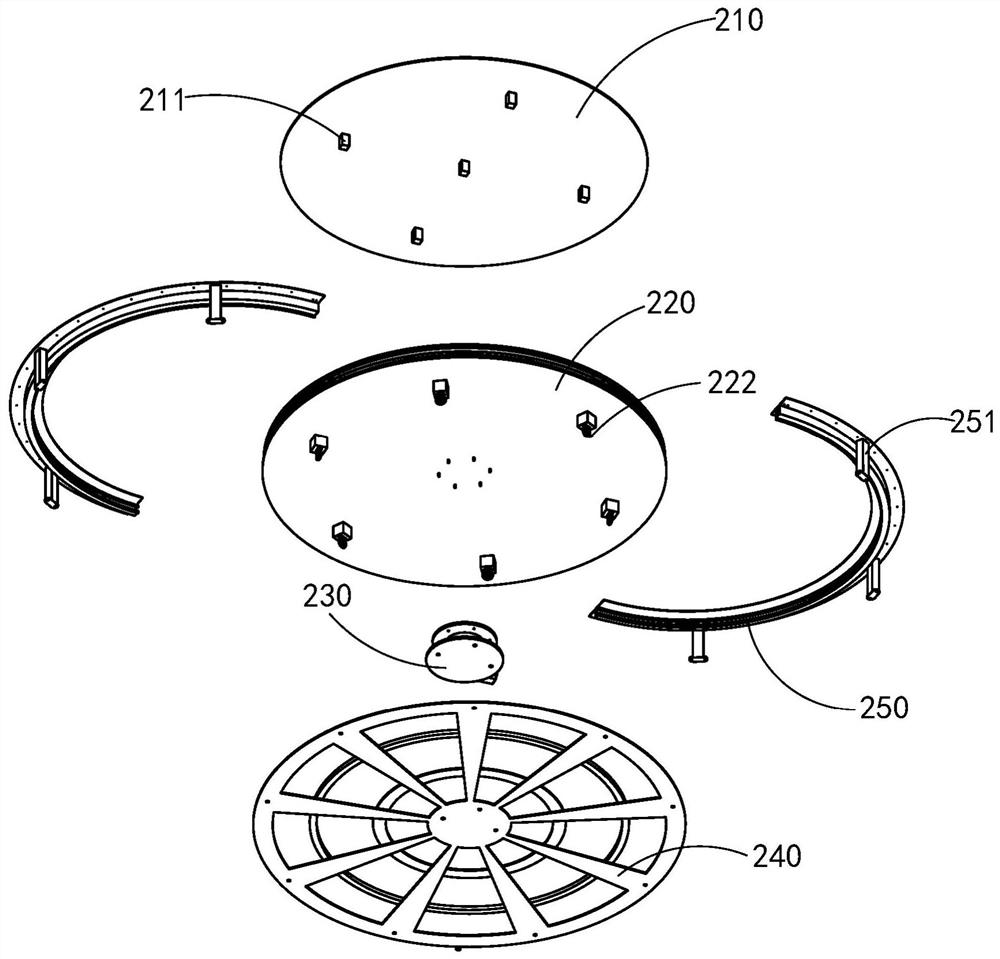

[0049] Such as Figure 1A and Figure 1B As shown, the dust removal system for electrical panel cabinets according to the present invention generally includes a dust removal room 100 , a rotary table 200 and a dust removal device 300 .

[0050] The dust removal room 100 is a place for dust removal and cleaning of electrical panel cabinets (not shown). By placing the electrical screen cabinet in the dust removal room 100, and the operator operates the dust removal equipment 300 outside the dust removal room 100 to clean the electrical screen cabinet, this not only reduces the dust pollution to the environment, but also reduces the burden on the operator. Physical health injury.

[0051] In one embodiment, the dust removal room 100 is transparent, so that the operator can observe the cleaning situation of the electrical panel cabinet in real time. Of course, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com