Forming method of high-temperature alloy fairing with reinforcing rib structure

A superalloy and reinforcing rib technology is applied in the forming field of superalloy fairing parts to achieve the effects of controlling welding deformation, improving forming accuracy and qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0030] This embodiment proposes a method for forming a superalloy fairing with a ribbed structure, the forming method includes the following steps:

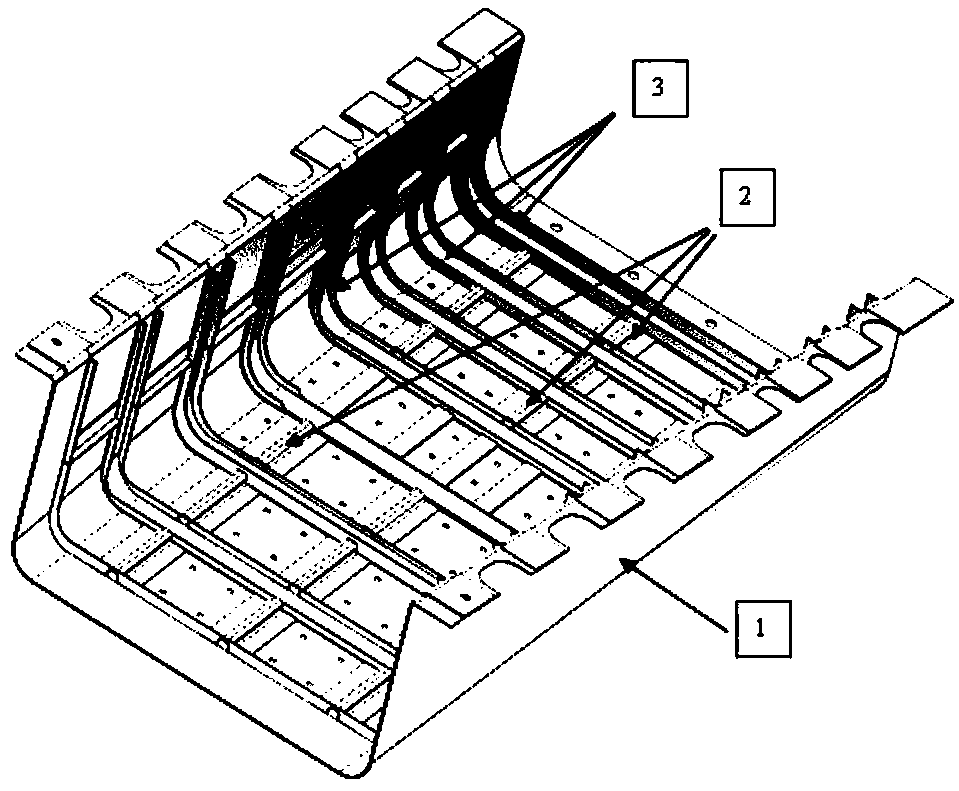

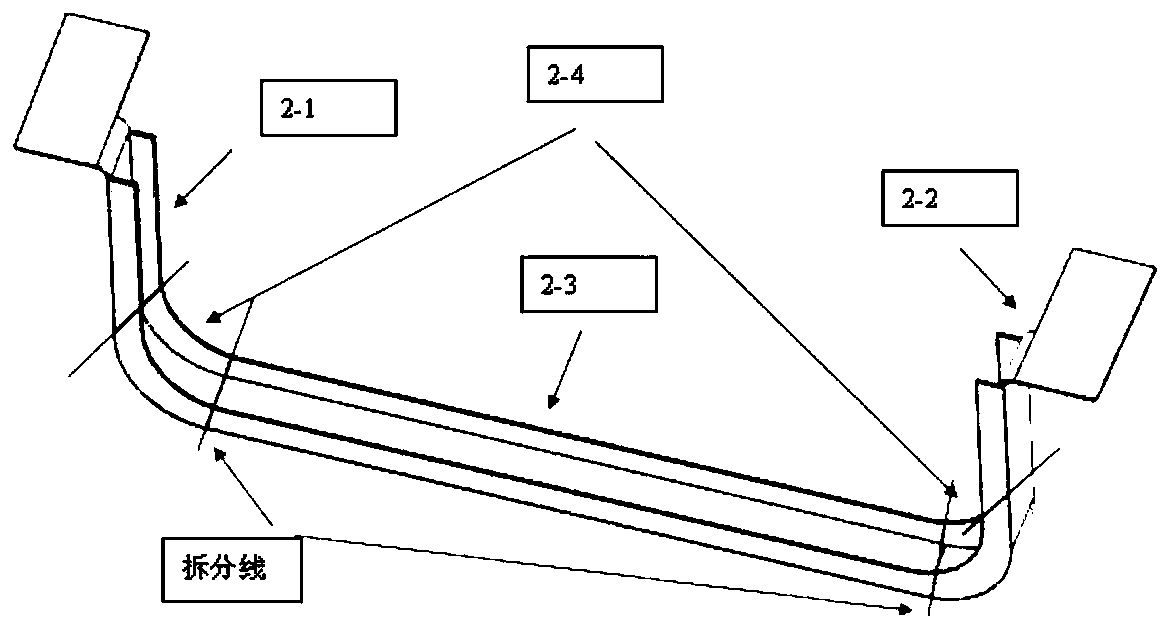

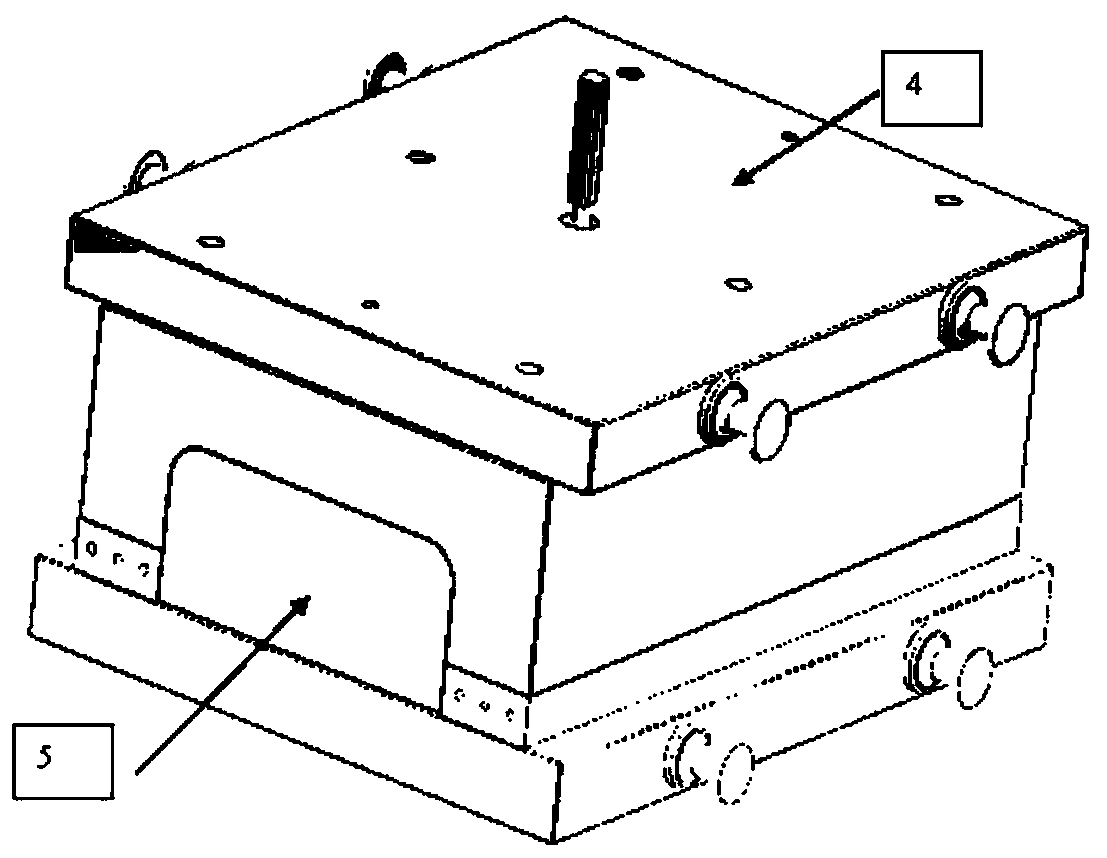

[0031] S1, such as figure 1 As shown, the materials of skin 1, longitudinal rib 2 and ring rib 3 are all high-temperature alloys with a thickness of 1mm. All longitudinal ribs 2 are designed as Ω-shaped, and ring rib 3 is divided into the left section of ring rib 2-1 , ring rib middle section 2-2, ring rib right section 2-3, ring rib angle piece 2-4 (four). In this split method, the ring rib is broken at the bottom fillet, but it does not affect the strengthening effect of the ring rib. Among them, the left, middle, and right sections of the ring reinforcement are U-shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com