Soft pneumatic finger with built-in skeleton

A pneumatic finger and software technology, applied in manipulators, chucks, manufacturing tools, etc., can solve the problems of insufficient torsional stiffness and poor torsional resistance of soft pneumatic fingers, and achieve good torsional stiffness, improved torsional stiffness, and good bending stiffness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

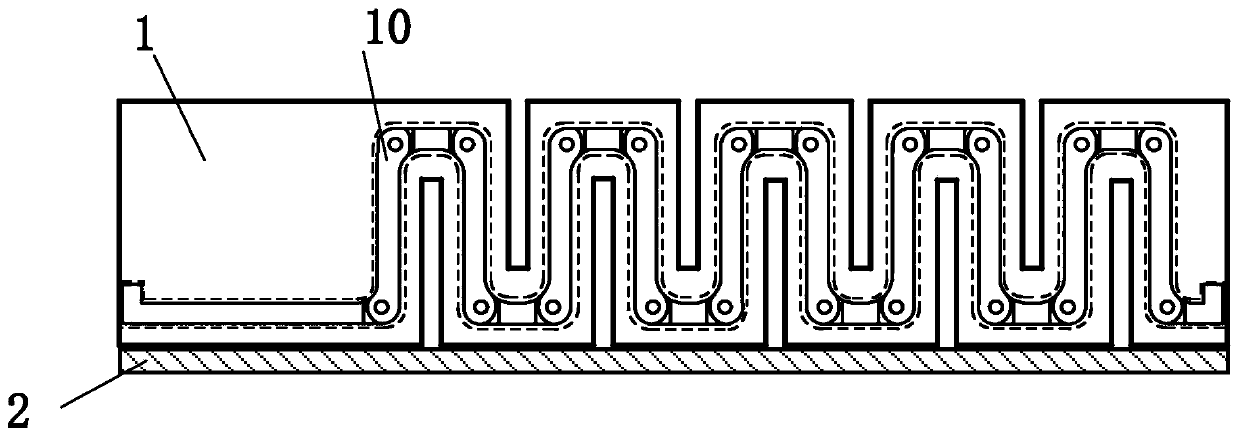

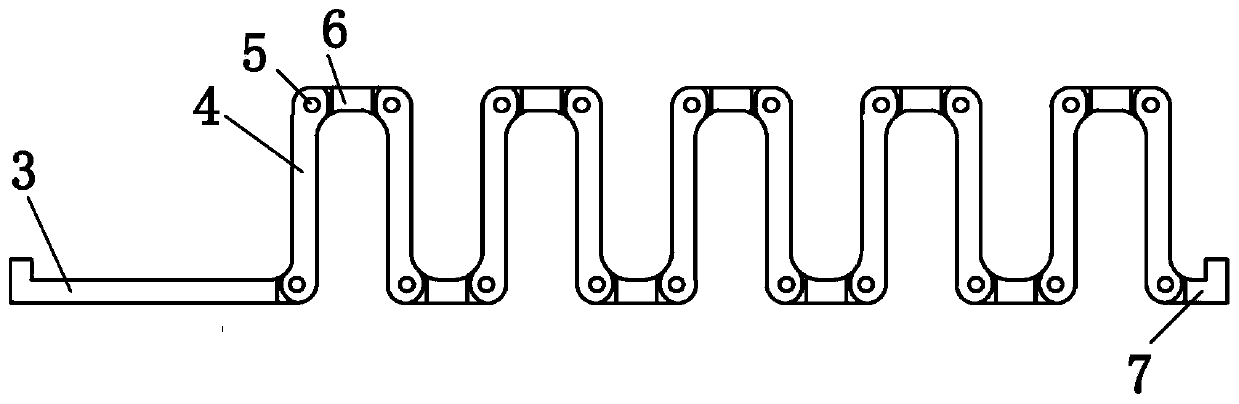

[0021] Such as figure 1 As shown, a soft pneumatic finger with an embedded skeleton includes a soft pneumatic finger and an embedded skeleton 10. The soft pneumatic finger is mainly composed of a body 1, and may further include an appendage 2. When the appendage 2 is included, the appendage 2 It is fixedly connected with the bottom surface of the main body 1 (that is, the lower side in the figure); the embedded frame 10 is connected with the main body 1 at both ends, and the main body part is not in direct contact with the main body 1 .

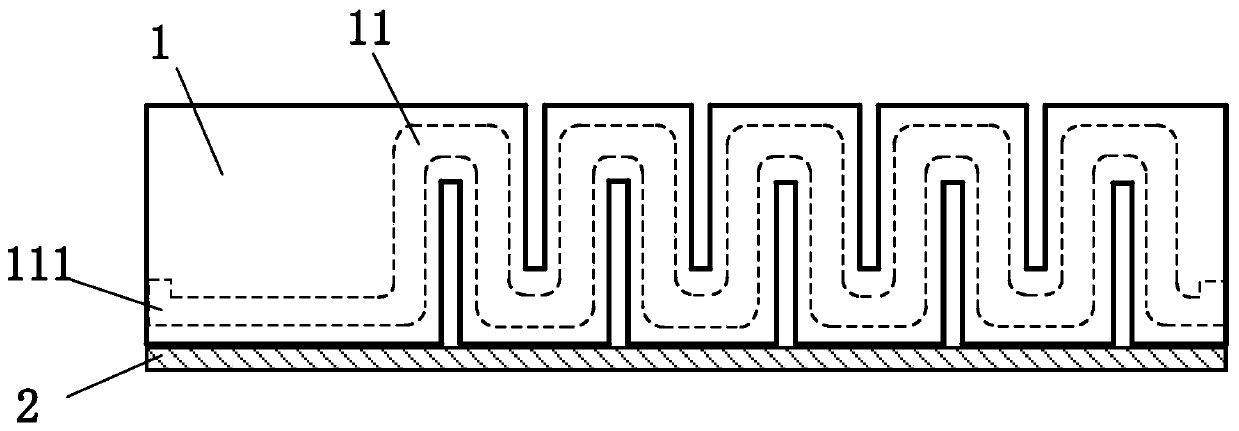

[0022] Such as figure 2 As shown, the overall shape of the body 1 can be described as meandering along the length direction, that is, bow-shaped or bow-like, and a closed air cavity 11 that is also bow-shaped or bow-like is arranged inside, and one end of the closed air cavity 11 The part is the vent 111 com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com