Structure of homonymous parallel double-screw-rod extrusion machine

A twin-screw extruder and screw technology, which is applied in the structural field of co-rotating parallel twin-screw extruders, can solve the problem of low production efficiency and the structure of co-rotating parallel twin-screw extruders has not been improved, installed, combined, and overhauled problems such as long work process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0097] The present invention will be further explained below in conjunction with the accompanying drawings.

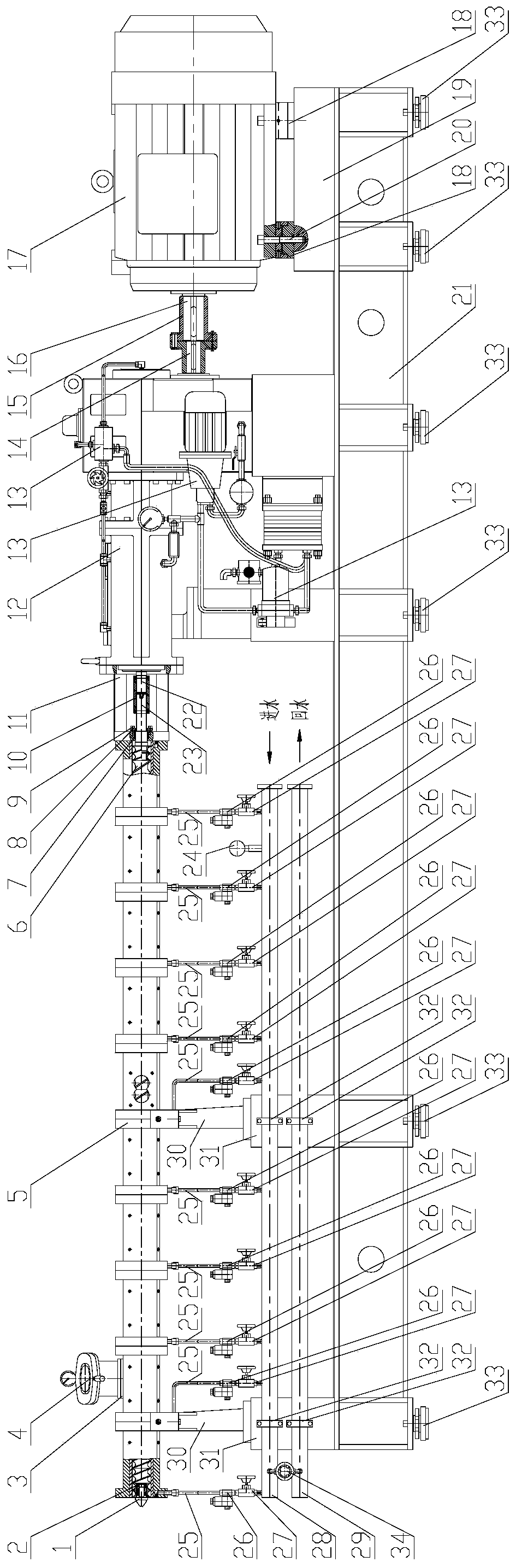

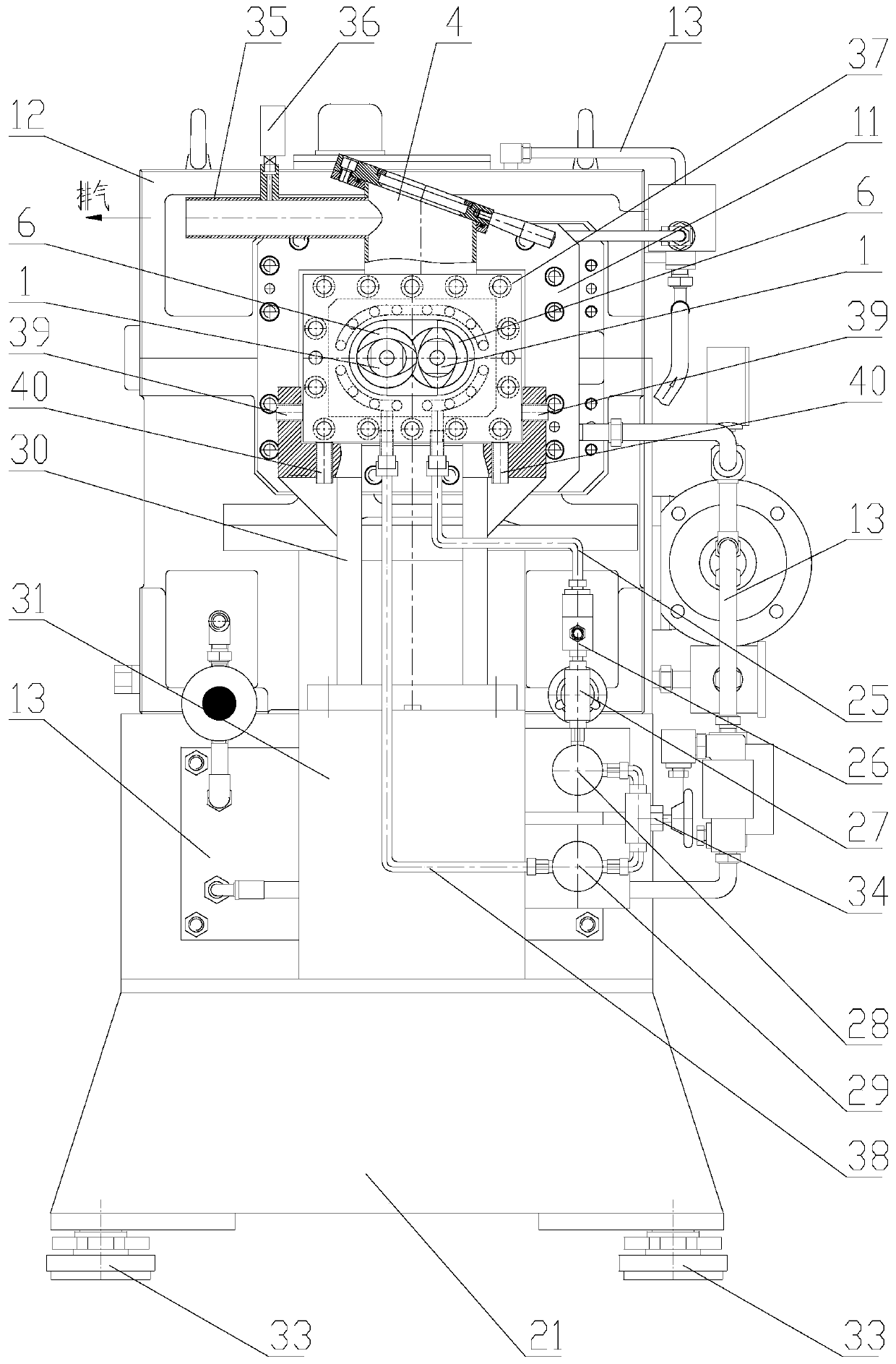

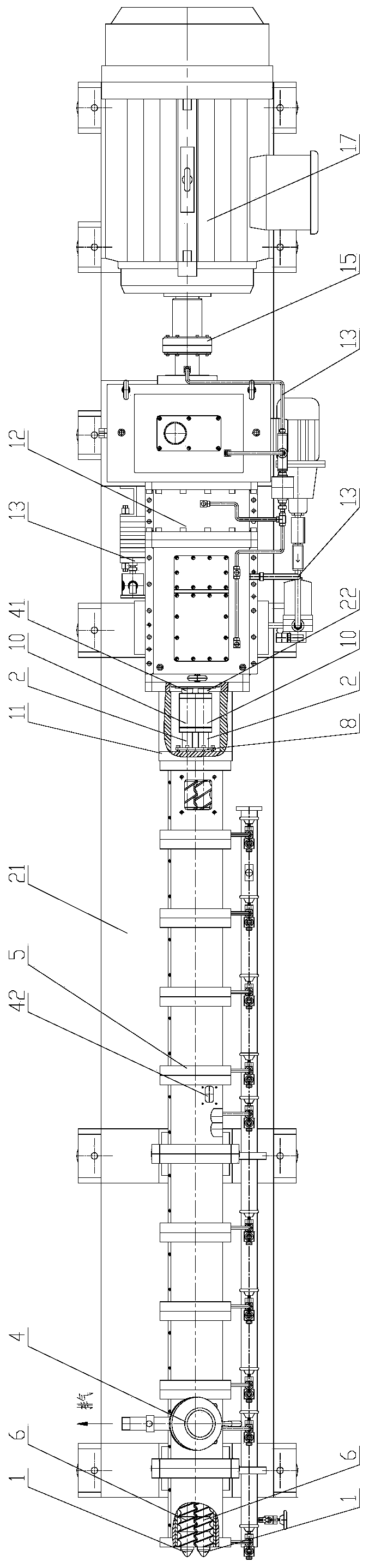

[0098] Such as Figures 1 to 3 As shown, the structure of the co-rotating parallel twin-screw extruder of the present invention includes a barrel component 5, a screw component 6, a gear reduction box 12, a motor 17, and a base 21.

[0099] A number of anti-vibration pads 33 are installed below the base 21 . According to the situation of the whole machine installation ground of the co-rotating parallel twin-screw extruder, adjust each anti-shock pad iron 33 to be in close contact with the installation ground and the horizontal installation position of the whole machine to ensure the stability of the whole machine during operation.

[0100] On the supporting seat 31 of the upper front part and the front middle part of the base 21, a cylinder support 30 is installed respectively, the cylinder body composition 5 is installed on the top of the cylinder support 30, and set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com