High-speed bag machine

A bag making machine, high-speed technology, applied in bag making operations, container manufacturing machinery, flexible container manufacturing, etc., can solve the problems of poor machine applicability, affecting folding effect, low work efficiency, etc. Efficiency, time-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

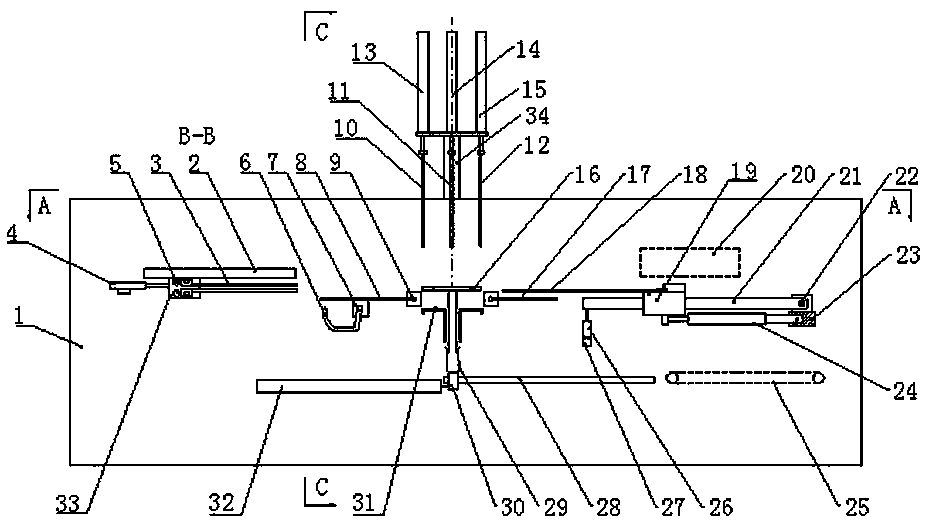

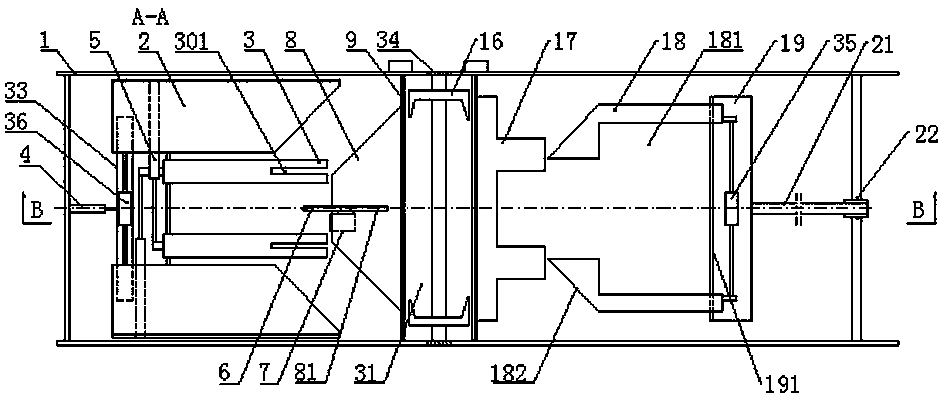

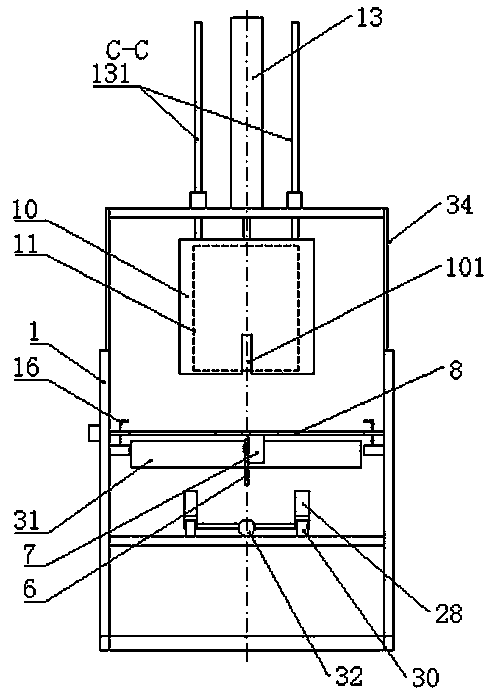

[0025] see Figure 1-Figure 9 , a kind of high-speed bag-making machine of the present invention, comprises finished product input unit, product folding unit, product transshipment unit, binding unit and product output unit 25, the finished product input unit will form vest-shaped plastic bag finished product after punching mouth and input to product On the top of the folding unit, the latter folds the finished plastic bag, and transports it to the strapping unit for binding through the product transfer unit, and finally outputs it from the product output unit to complete the entire bag making process; the product folding unit includes: The two handles at the front end of the vest-shaped plastic bag are folded in the middle, and the front corner folding mechanism is used to fold the front part of the plastic bag back. The bag-pressing hook 6 that swings upwards and backwards is driven by the hook-driving cylinder 7 installed under the front end of the front flap 8, and the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com