Automobile skylight sealing strip

A technology for automobile sunroof and sealing strip, applied in the direction of sealing device, engine sealing, vehicle parts, etc., can solve the problems of affecting sealing, affecting the interior environment of the car, sanitary dead corners, etc., to prevent stretching and shrinking, and not easy to sanitary dead corners , The effect of installation is firm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

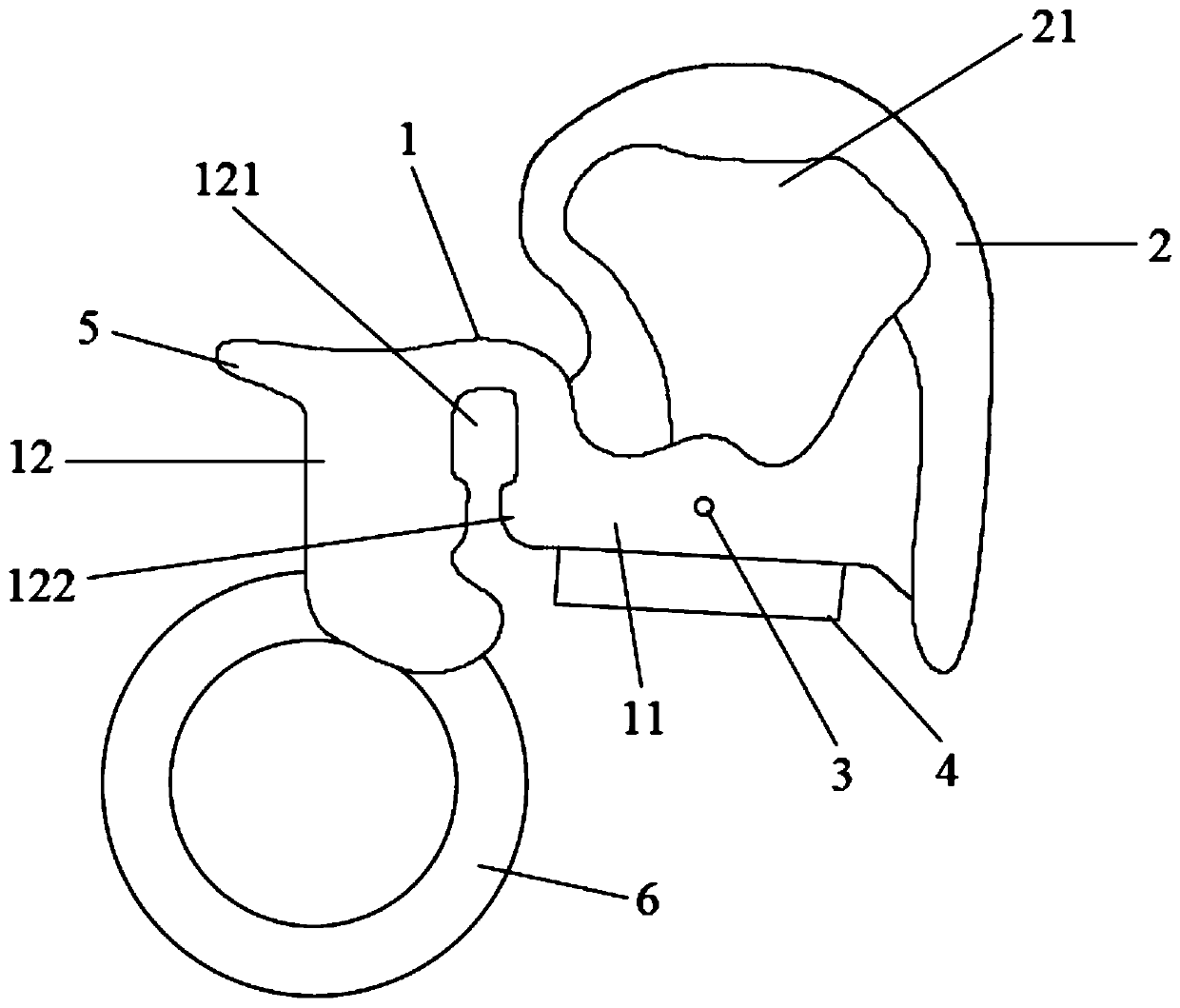

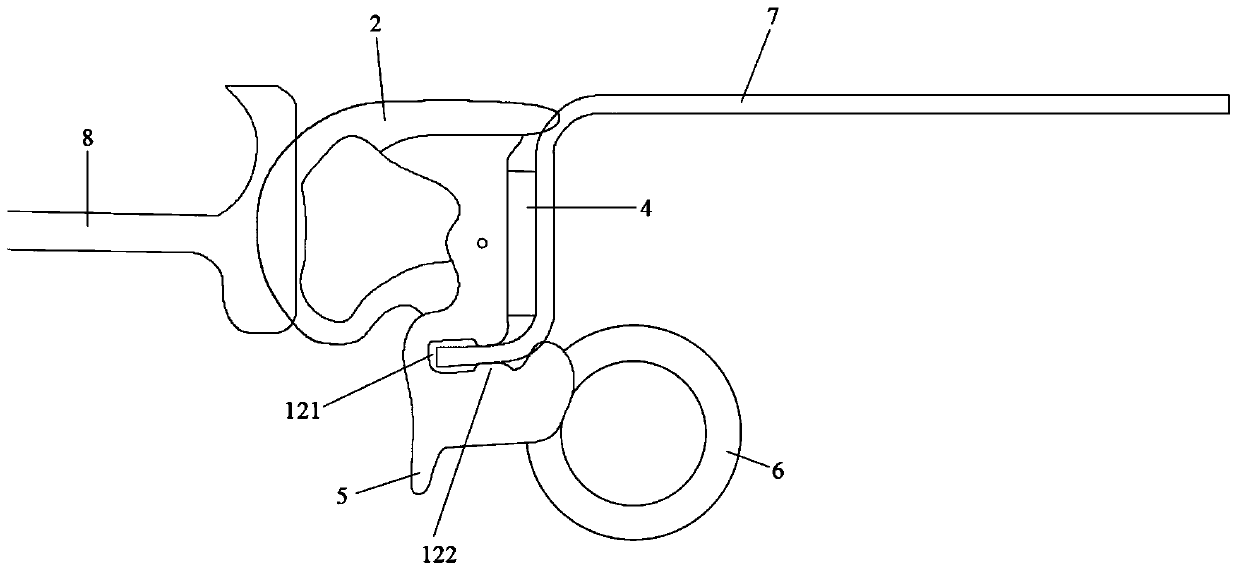

[0030] See figure 1 , figure 1 It is a transverse sectional view of an automobile sunroof sealing strip of the present invention. The automotive sunroof sealing strip is provided with a fixing part 1 and a sealing part 2. The fixing part 1 includes a first fixing part 11 and a second fixing part 12. Fiber threads 3 are embedded inside the first fixing part 11. An adhesive tape 4 is provided on the bottom surface of a fixed portion 1, the sealing portion 2 is located above the first fixed portion 11, and the middle of the sealing portion 2 is a hollow buffer cavity 21, and the second fixed portion 12 is connected to the On the left side wall of the first fixed part 11, the second fixed part 12 is provided with a card slot 121, and the two side walls inside the card slot 121 are all provided with a fixed rack 122, and the left side wall of the second fixed part 12 is also provided with There is a lip 5 , and a circular bubble tube 6 is provided at the lower end of the second f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com