Multi-row ultra-deep oblique composite anchor pile for narrow space

A composite bolt and bolt technology, which is used in excavation, construction, infrastructure engineering, etc., can solve the problems of thin supporting structure system, insufficient supporting strength, inability to do anything in deep foundation pits, etc., and achieve good anchoring effect and reinforcement effect. Good, reduce the effect of the use of hoisting machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

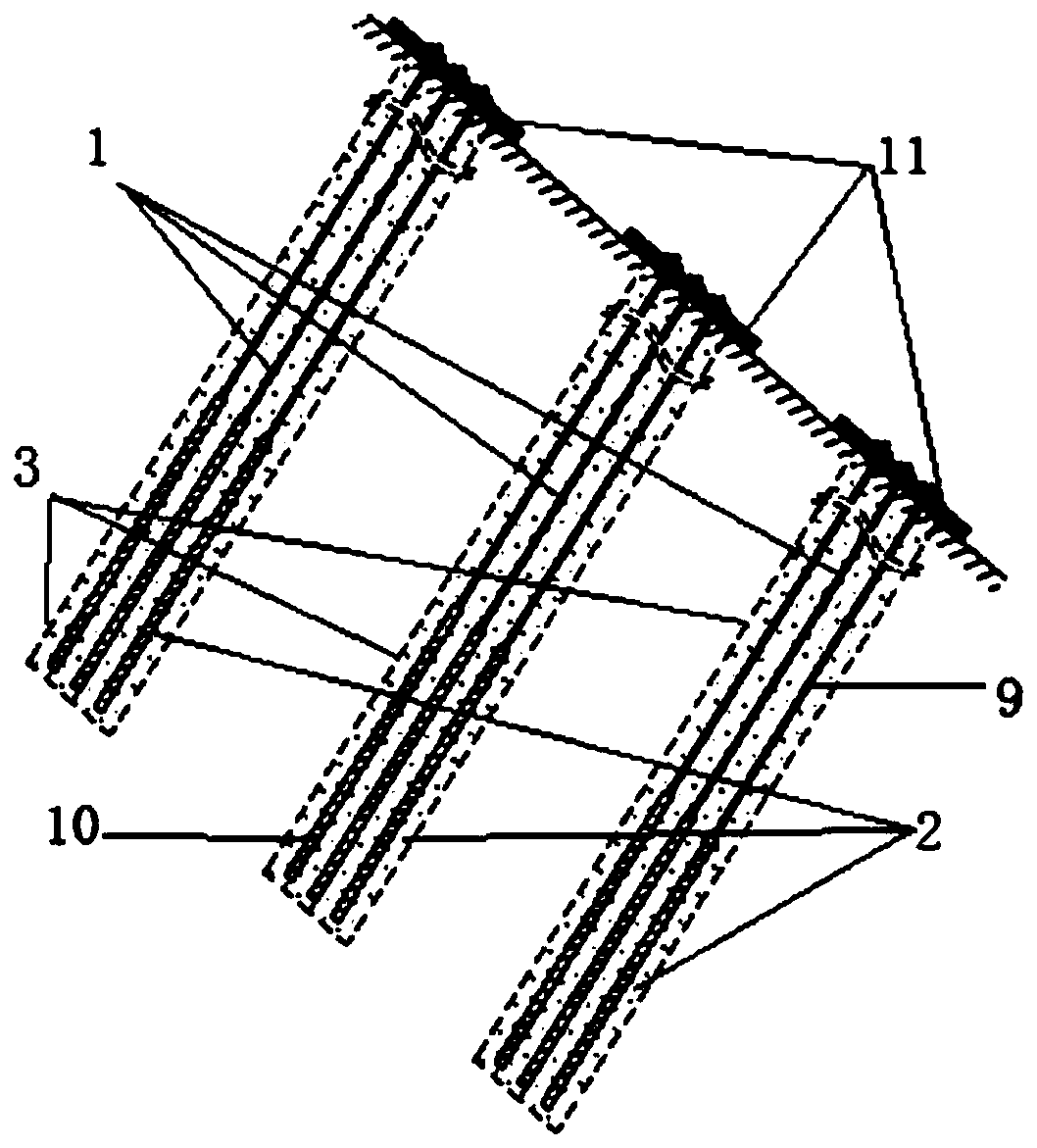

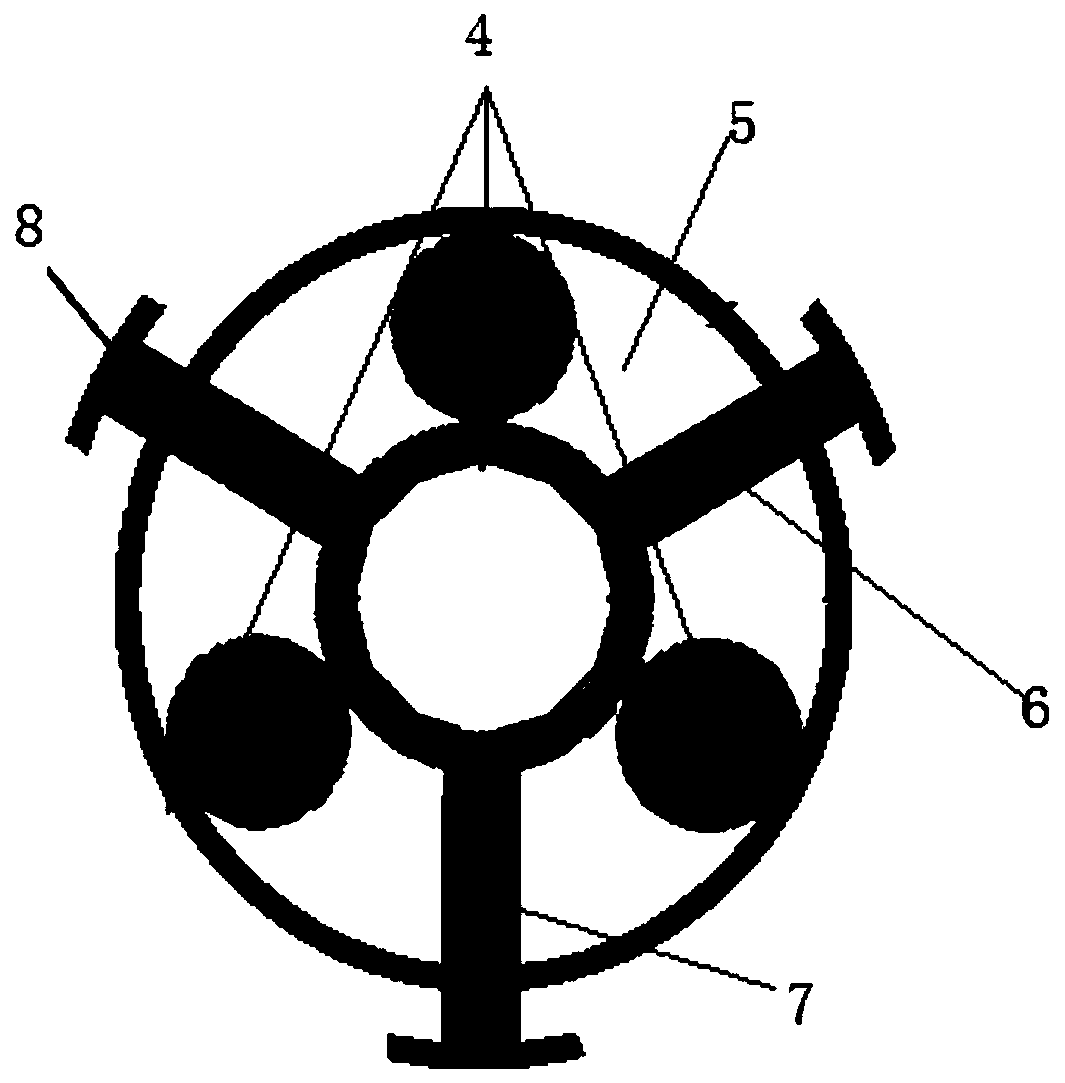

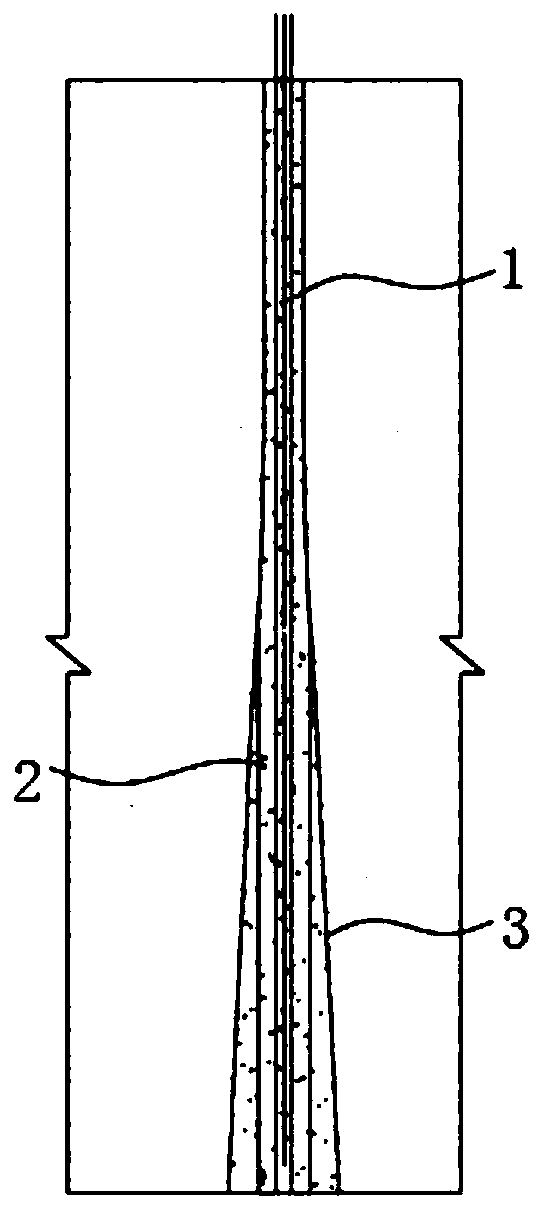

[0035] see Figure 1-4 , a multi-row ultra-deep oblique composite anchor pile for a narrow space, each composite anchor pile includes an anchor main structure 1 and a slurry consolidation body 2, and the slurry consolidation body 2 is filled in the anchor Around the main body structure 1 of the anchor rod; the main body structure 1 of the anchor rod includes a plurality of anchor rods 4, connectors 5 and limit fixtures 6, the connector 5 is circular, and a plurality of through holes are evenly arranged on its circumference, so The through holes are used to pass through the plurality of anchor rods 4, so that they are connected in a circular distribution; there are multiple connecting parts 5, which are evenly spaced along the length direction of the plurality of anchor rods 4; each The connecting member 5 is provided with three limit fixing members 6, and the limit fixing members 6 are evenly spaced on the circumference of the connecting member 5; the limit fixing member 6 inc...

Embodiment 2

[0051] see Figure 1-4 , a multi-row ultra-deep oblique composite anchor pile for a narrow space, each composite anchor pile includes an anchor main structure 1 and a slurry consolidation body 2, and the slurry consolidation body 2 is filled in the anchor Around the main body structure 1 of the anchor rod; the main body structure 1 of the anchor rod includes a plurality of anchor rods 4, connectors 5 and limit fixtures 6, the connector 5 is circular, and a plurality of through holes are evenly arranged on its circumference, so The through holes are used to pass through the plurality of anchor rods 4, so that they are connected in a circular distribution; there are multiple connecting parts 5, which are evenly spaced along the length direction of the plurality of anchor rods 4; each The connecting member 5 is provided with three limit fixing members 6, and the limit fixing members 6 are evenly spaced on the circumference of the connecting member 5; the limit fixing member 6 inc...

Embodiment 3

[0080] see Figure 1-4 , a multi-row ultra-deep oblique composite anchor pile for a narrow space, each composite anchor pile includes an anchor main structure 1 and a slurry consolidation body 2, and the slurry consolidation body 2 is filled in the anchor Around the main body structure 1 of the anchor rod; the main body structure 1 of the anchor rod includes a plurality of anchor rods 4, connectors 5 and limit fixtures 6, the connector 5 is circular, and a plurality of through holes are evenly arranged on its circumference, so The through holes are used to pass through the plurality of anchor rods 4, so that they are connected in a circular distribution; there are multiple connecting parts 5, which are evenly spaced along the length direction of the plurality of anchor rods 4; each The connecting member 5 is provided with three limit fixing members 6, and the limit fixing members 6 are evenly spaced on the circumference of the connecting member 5; the limit fixing member 6 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com