Construction method used for superhigh building fire elevator shaft wall and reinforced concrete wall

A technology of reinforced concrete and fire-fighting elevators, which is applied to walls, fire prevention, vertical pipes, etc., can solve the problems of alleviating the transportation pressure of super high-rise materials, complicated construction procedures, and less manpower input, saving manpower, reducing manpower input, and reducing labor costs. The effect of reducing transport pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

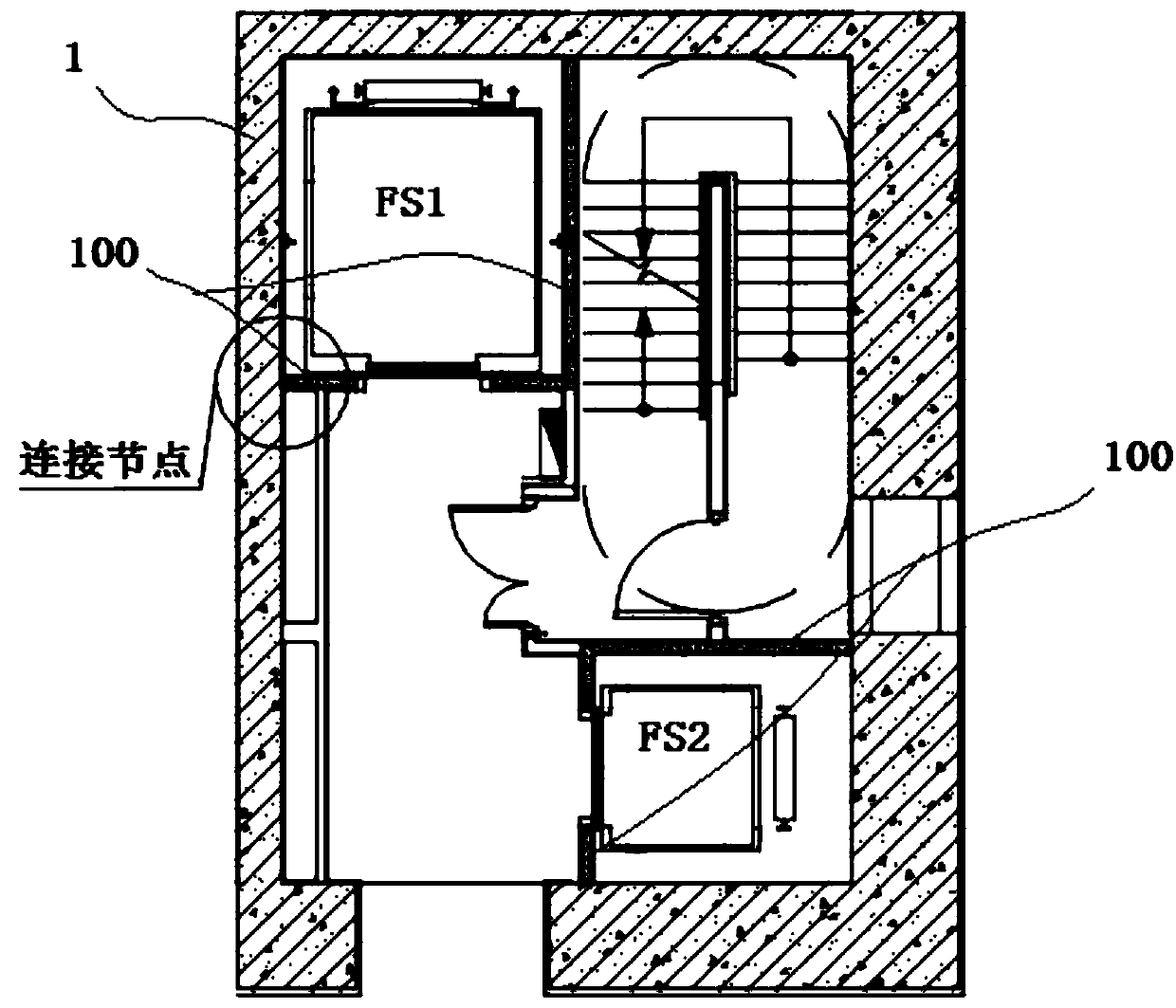

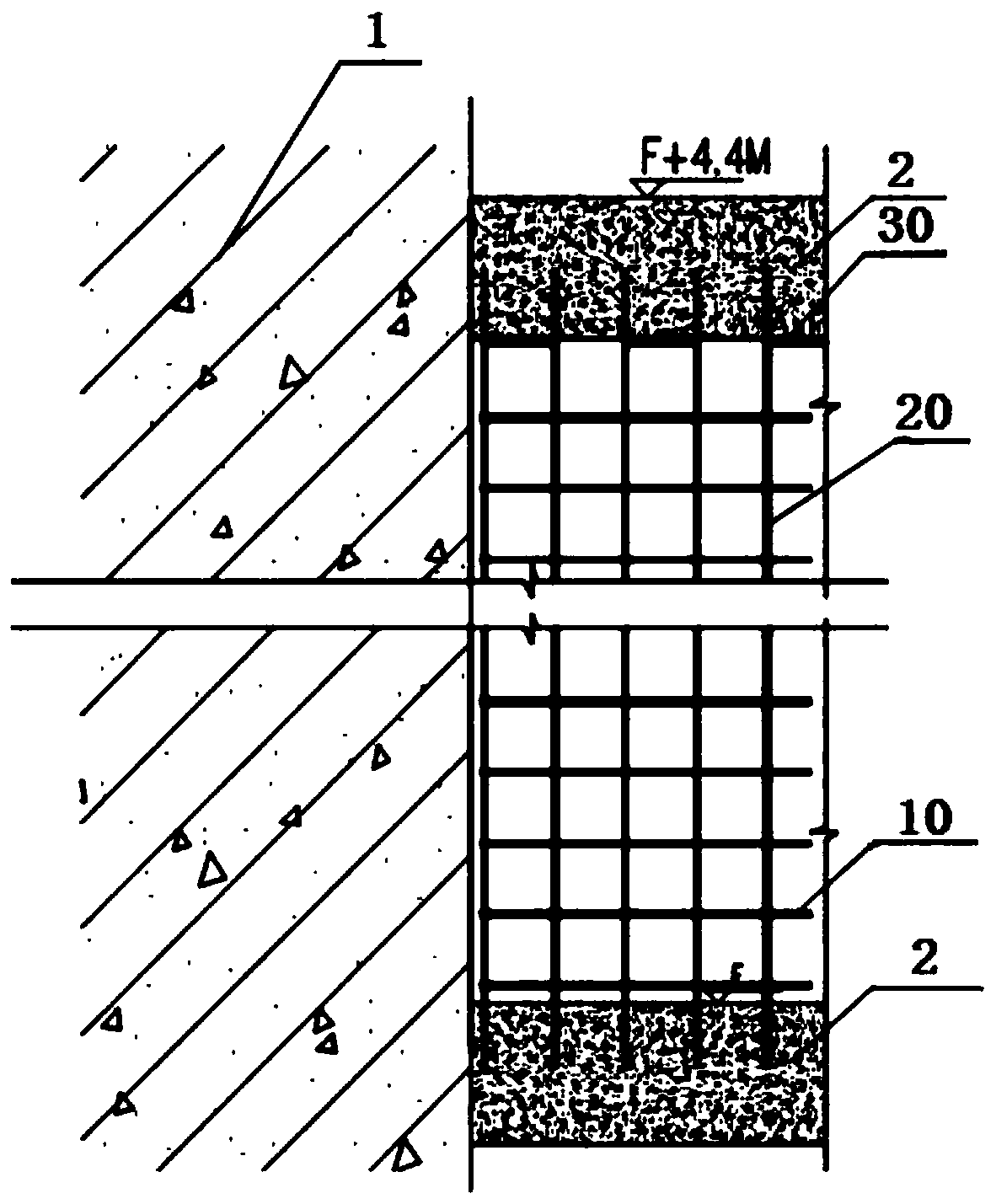

[0032] see Figure 1 to Figure 5 , the construction method for the super high-rise fire elevator shaft wall provided in this embodiment, according to the original design drawings, the masonry wall is changed to a reinforced concrete wall 100, the design confirms the reinforcement and concrete number, the wall reinforcement binding and concrete construction Simultaneously with the construction of the core tube structure of the super high-rise fire elevator shaft, the overall shaft and core tube structure of the super high-rise fire elevator are formed at one time. It saves the process of secondary structure construction in the later stage, saves resources such as manpower and construction period, and advances the construction time for the removal of construction elevators and filling vacancies of curtain walls.

[0033] The present invention utilizes the construction method of one-time molding of the fire elevator shaft to change the masonry wall into a reinforced concrete wall...

Embodiment 2

[0041] like Figure 1 to Figure 5 As shown, the present invention also provides a reinforced concrete wall 100, which is used as a super high-rise fire elevator shaft wall, which is configured to ensure the overall rigidity, design and calculation to confirm the number of reinforcement and concrete, wall reinforcement and concrete The construction is synchronized with the construction of the core tube structure of the super high-rise fire elevator shaft, so that the overall shaft and core tube structure of the super high-rise fire elevator are formed at one time.

[0042] like figure 1 As shown, in this embodiment, the thickness of the reinforced concrete wall 100 is 120 mm, and double rows of D10@200 steel bars are arranged inside according to the structural requirements. wall.

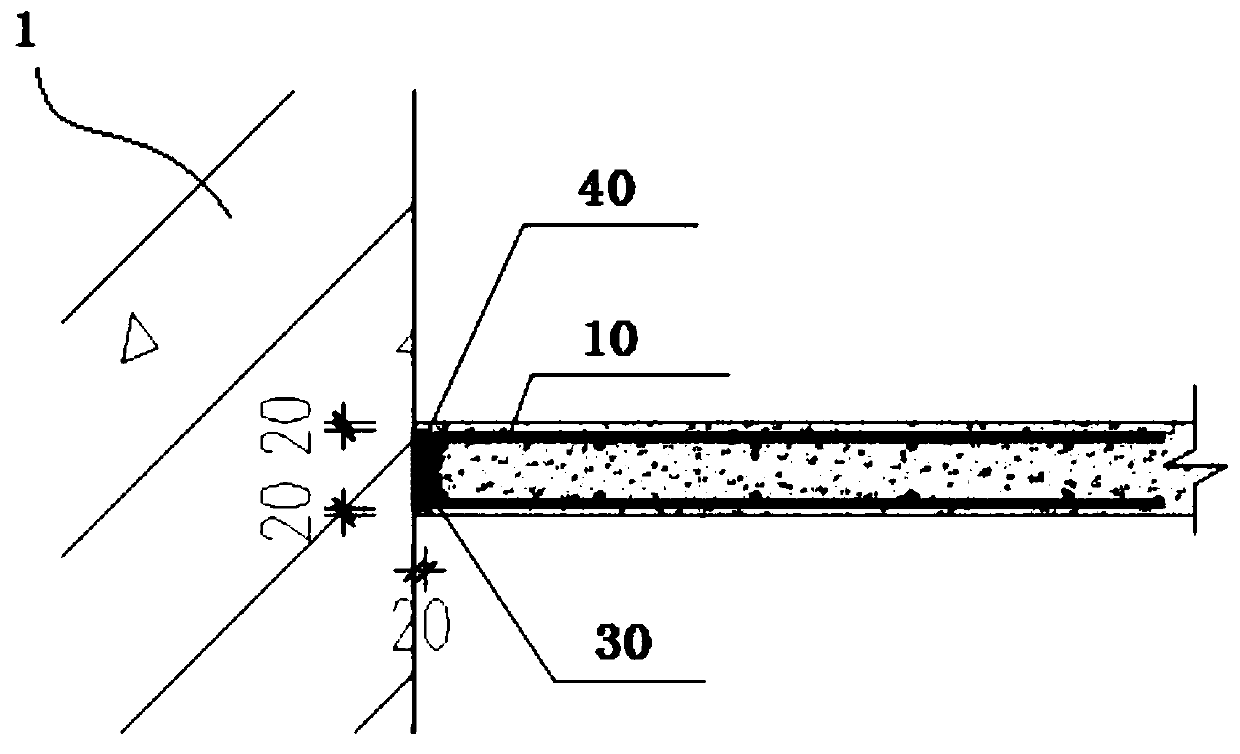

[0043] like figure 2 As shown, in this embodiment, the horizontal bars 10 constructed in the reinforced concrete wall 100 are anchored into the core tube structural wall 1 every 400 mm.

[0044] l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com