Concrete pouring device

A technology of concrete and conveying devices, which is applied in the direction of construction, building structure, and building materials processing, can solve the problems of increasing workload and materials, increasing worker workload, increasing construction time, etc., to reduce workload, Efficient pouring area range and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

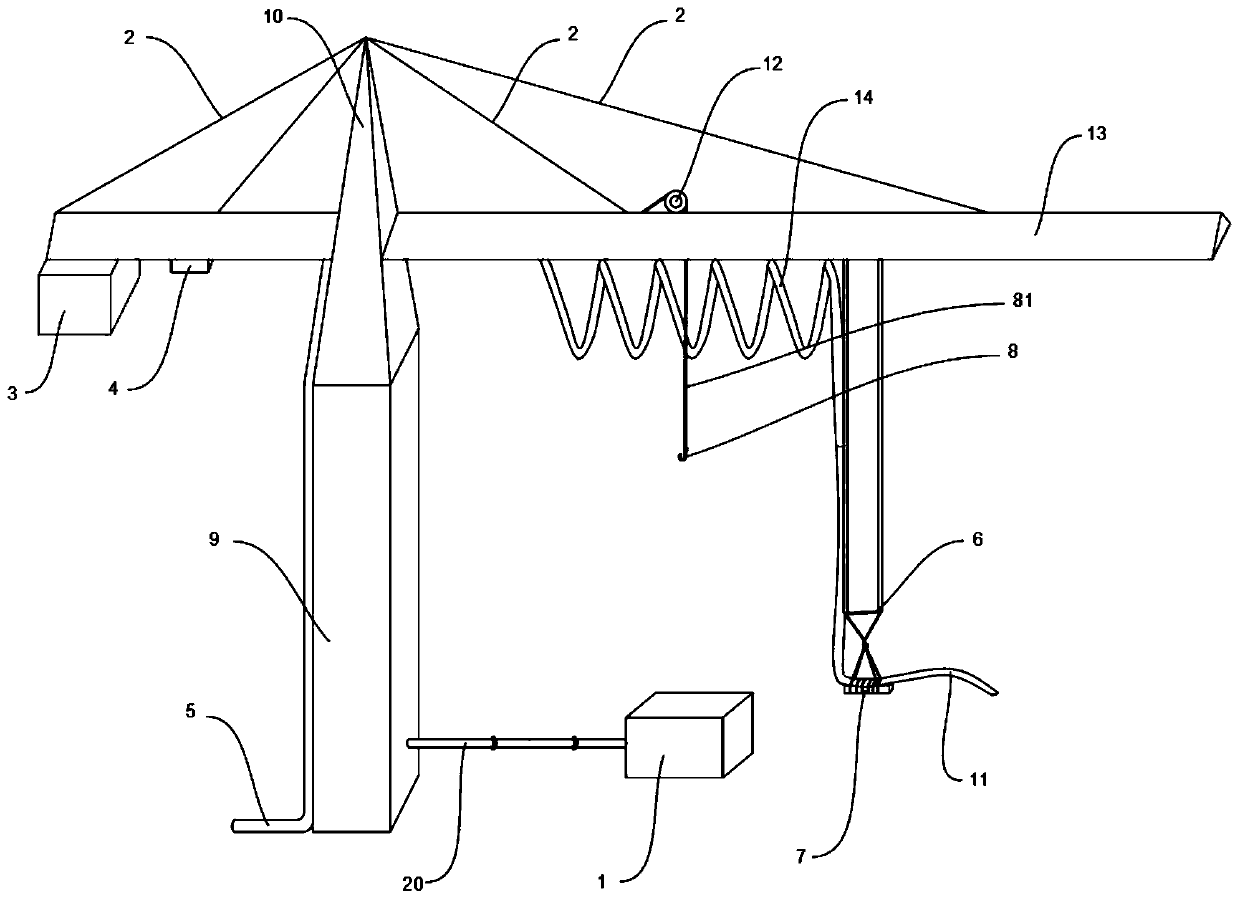

[0030] Such as figure 1As shown, a concrete conveying and pouring device in this embodiment includes a tower crane body, and a first conveying pipe for conveying concrete is arranged on the tower crane body. One end of the first conveying pipe is connected to a shock-absorbing conveying device, and the first conveying pipe A folded pipe 14 is provided at one end away from the shock-absorbing conveying device, and a concrete hose 11 is provided at the end of the folded pipe 14 away from the shock-absorbing conveying device.

[0031] The shock-absorbing conveying device is used to eliminate the vibration of the first conveying pipe during the concrete conveying process, prevent the folded pipe 14 from swinging during the concrete conveying process, and affect the stability of the tower crane body, resulting in inaccurate pouring positions and poor efficiency during concrete pouring. low. The folded pipe 14 is used to extend the first conveying pipe to further convey concrete, a...

Embodiment 2

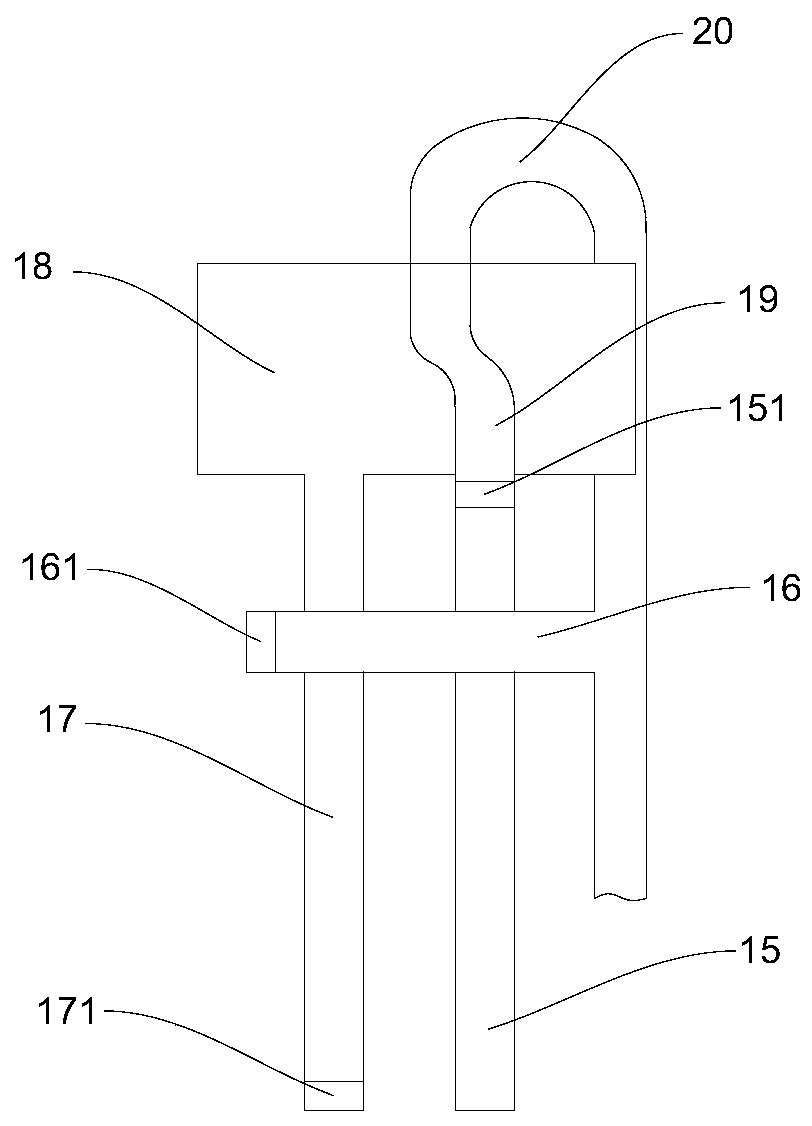

[0035] This embodiment is a definition optimized on the basis of the above-mentioned embodiment 1, such as figure 1 , figure 2 As shown, a concrete pouring device of this embodiment, the shock-absorbing conveying device includes a feed hopper 18 and a third cylinder 17 connected to the feed hopper 18, and the end of the third cylinder 17 away from the feed hopper 18 is provided with a first Three pistons 171; the feed hopper 18 is also provided with the first cylinder 15, the first cylinder 15 is positioned at one side of the third cylinder 17, and the first cylinder 15 is provided with the first piston 151 near the end of the feed hopper 18; The bucket 18 is provided with a guide tube 19, one end of the guide tube 19 is connected to the first cylinder 15, and the end of the guide tube 19 away from the first cylinder 15 is provided with a second delivery tube 20, and the second delivery tube 20 is far away from the feed hopper 18 One end of the second cylinder 16 is provided...

Embodiment 3

[0039] This embodiment is a definition optimized on the basis of the above-mentioned embodiment 1, such as figure 1 , figure 2 As shown, a concrete conveying and pouring device of this embodiment, the tower crane body includes a tower crane body 9 of a square structure, a tower crane cone 10 rotatably connected to the tower crane body 9 and a triangular beam frame arranged in the middle of the tower crane cone 10, the tower crane The conical body 10 is connected with the main body 9 of the tower crane through a rotating gear plate.

[0040] One end of the tower crane body 9 is connected to the ground, and one end of the tower crane body 9 away from the ground is connected to the tower crane cone 10 . In the middle of the connection between the tower crane main body 9 and the tower crane cone 10 is provided a pipe joint that can rotate 360 degrees. Folding tube 14 is arranged through tower crane main body 9, and is arranged along the axial direction of tower crane main bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com