A one-way plane torsion spring

A plane torsion spring and torsion spring technology, applied in the field of robotics, can solve the problems of reducing the reliability of the limit function, the failure of the limit cable, and the complex structure, achieving a large relative rotation range, protecting the torsion spring structure, and torque bearing. high volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

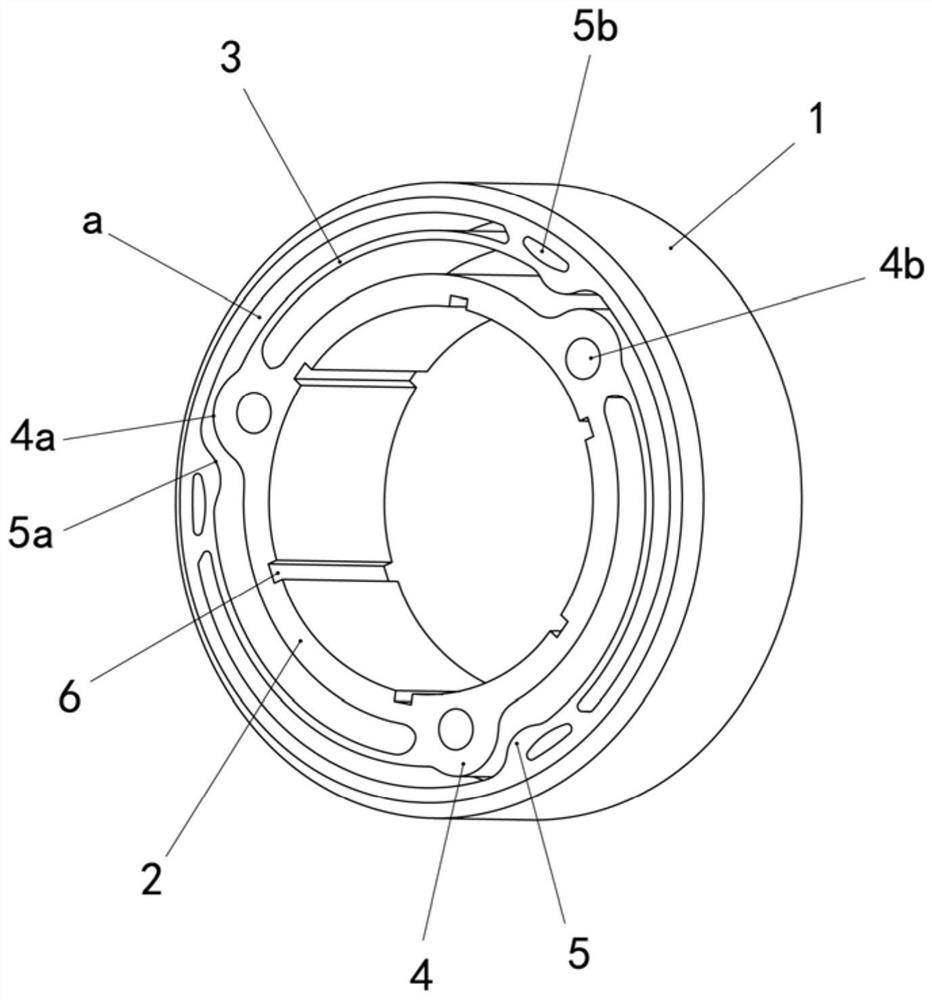

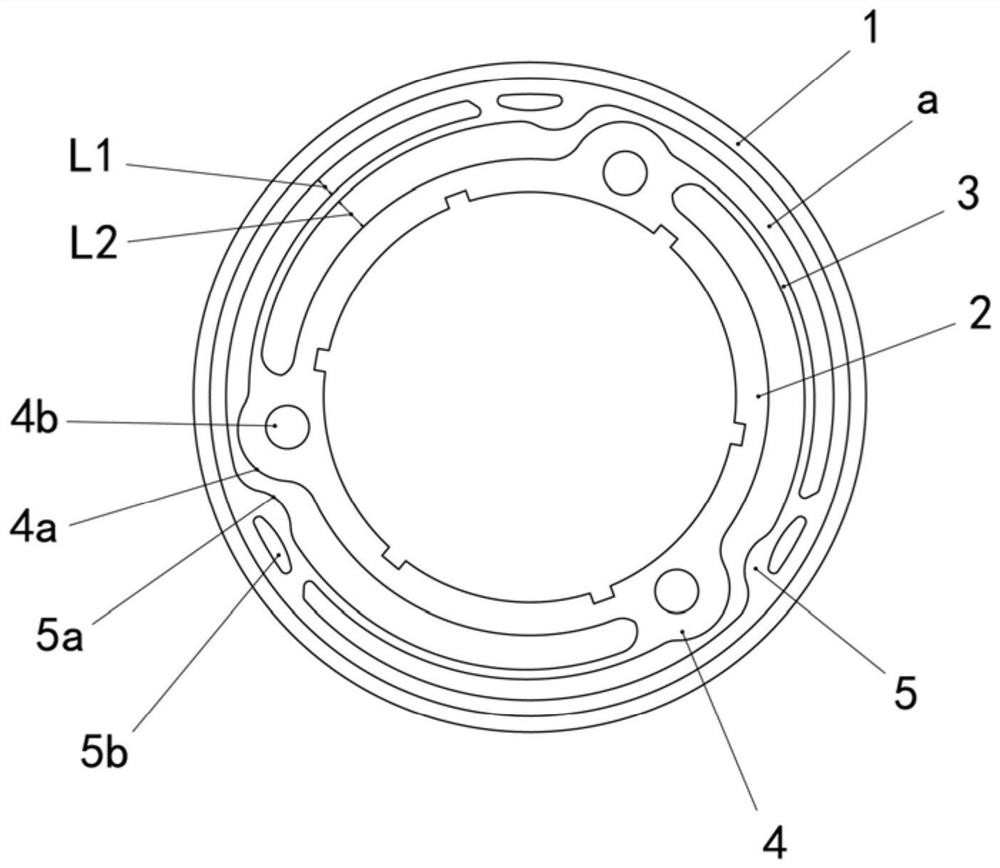

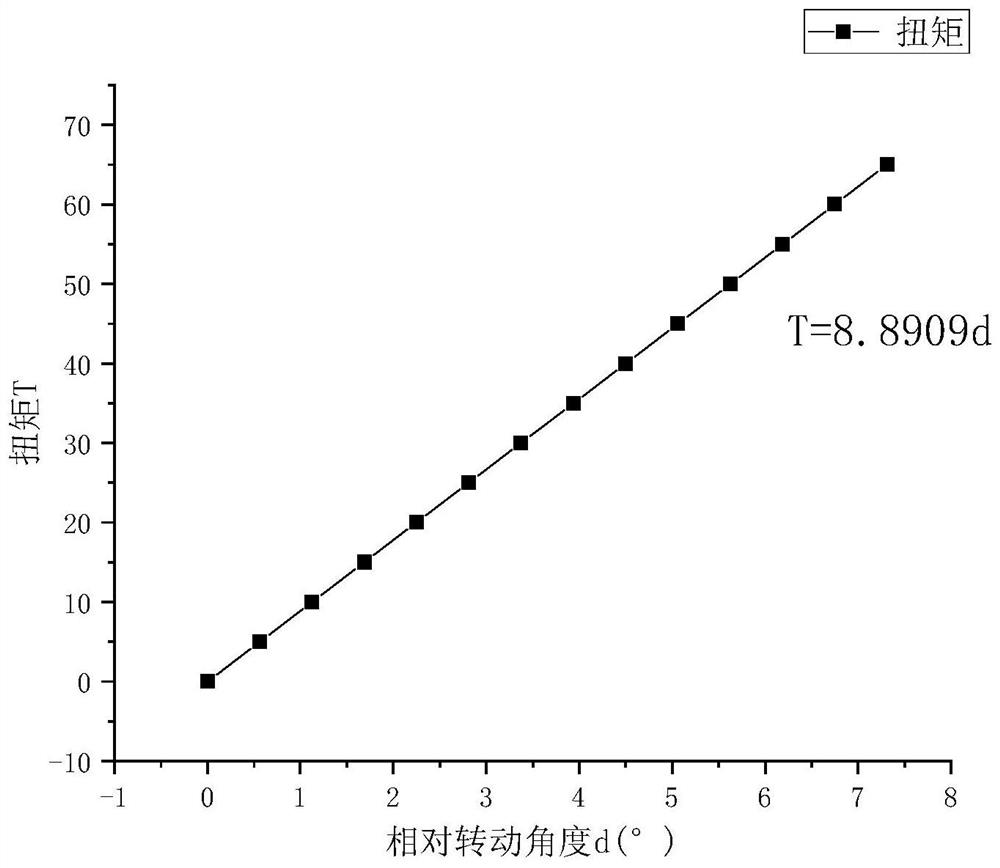

[0037] Such as figure 1 As shown in -5, a one-way planar torsion spring includes a torsion spring outer ring 1, a torsion spring inner ring 2, and a plurality of torsion spring elastic bodies 3, and there is a gap between the torsion spring outer ring 1 and the torsion spring inner ring 2 Space a, a plurality of torsion spring elastic bodies 3 are distributed in the gap space a between the torsion spring outer ring 1 and the torsion spring inner ring 2 .

[0038] One end of the torsion spring elastic body 3 is drawn from the inner peripheral surface of the torsion spring outer ring 1, along the outer peripheral direction of the torsion spring inner ring 2, taking the surrounding curve as the extension reference, and the other end of the torsion spring elastic body 3 extends to the torsion spring inner ring 2, the relative rotation between the torsion spring inner ring 2 and the torsion spring outer ring 1 along the extension direction of the torsion spring elastic body 3 will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com