Weakly cemented soft rock coring device and method

A coring device and weak cementation technology, applied in the field of rock mechanics, can solve problems affecting the accuracy and integrity of rock samples, coring disturbance, etc., and achieve the effect of avoiding multiple disturbance damage, avoiding flying, and high-precision coring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

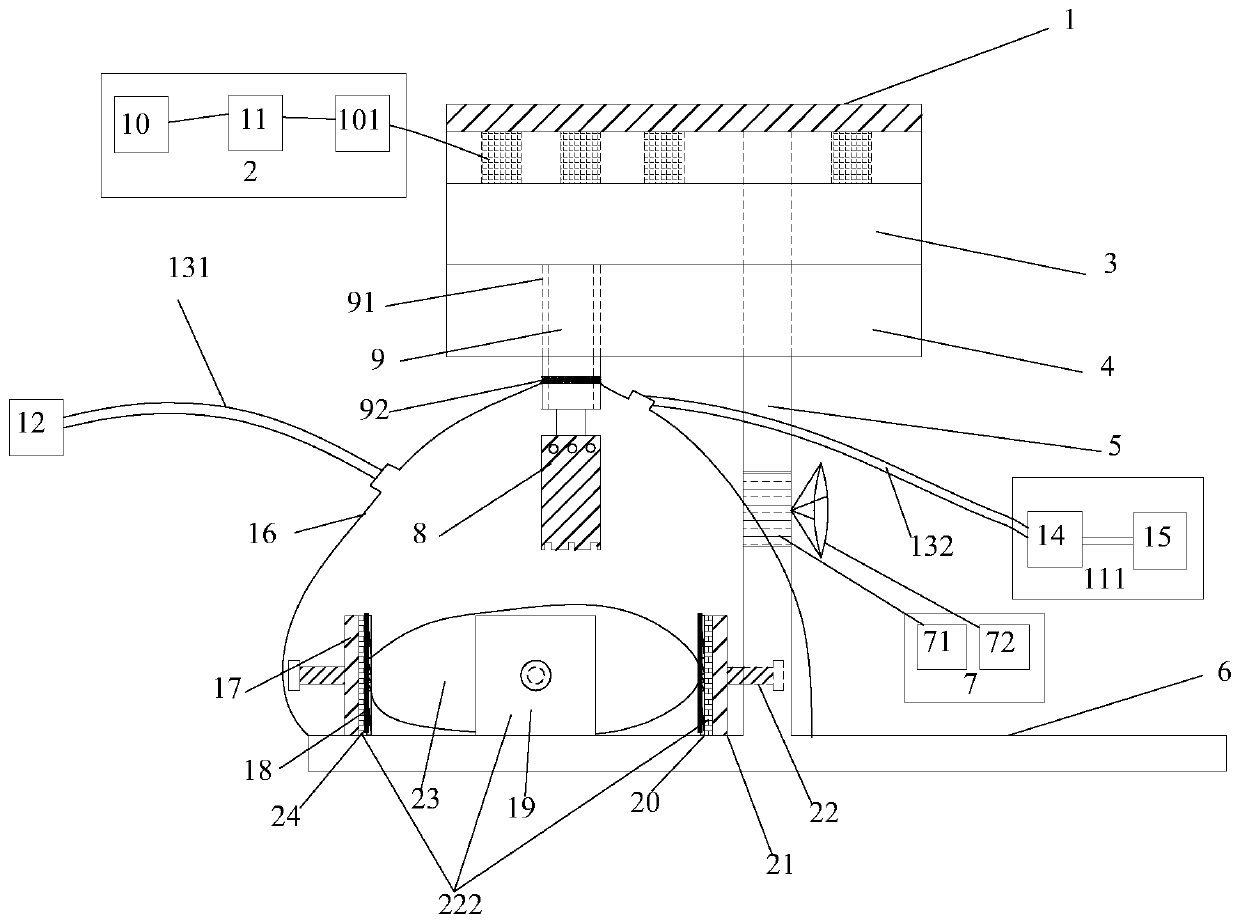

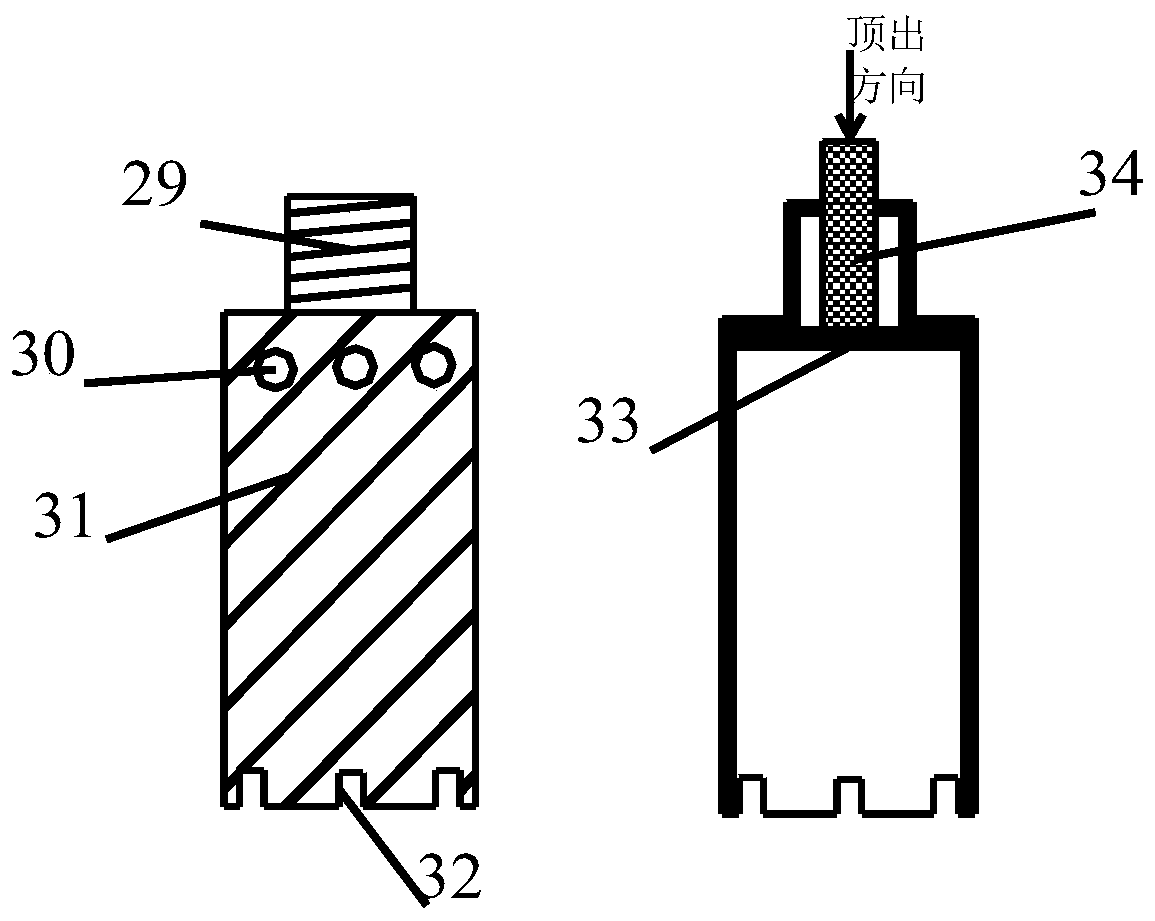

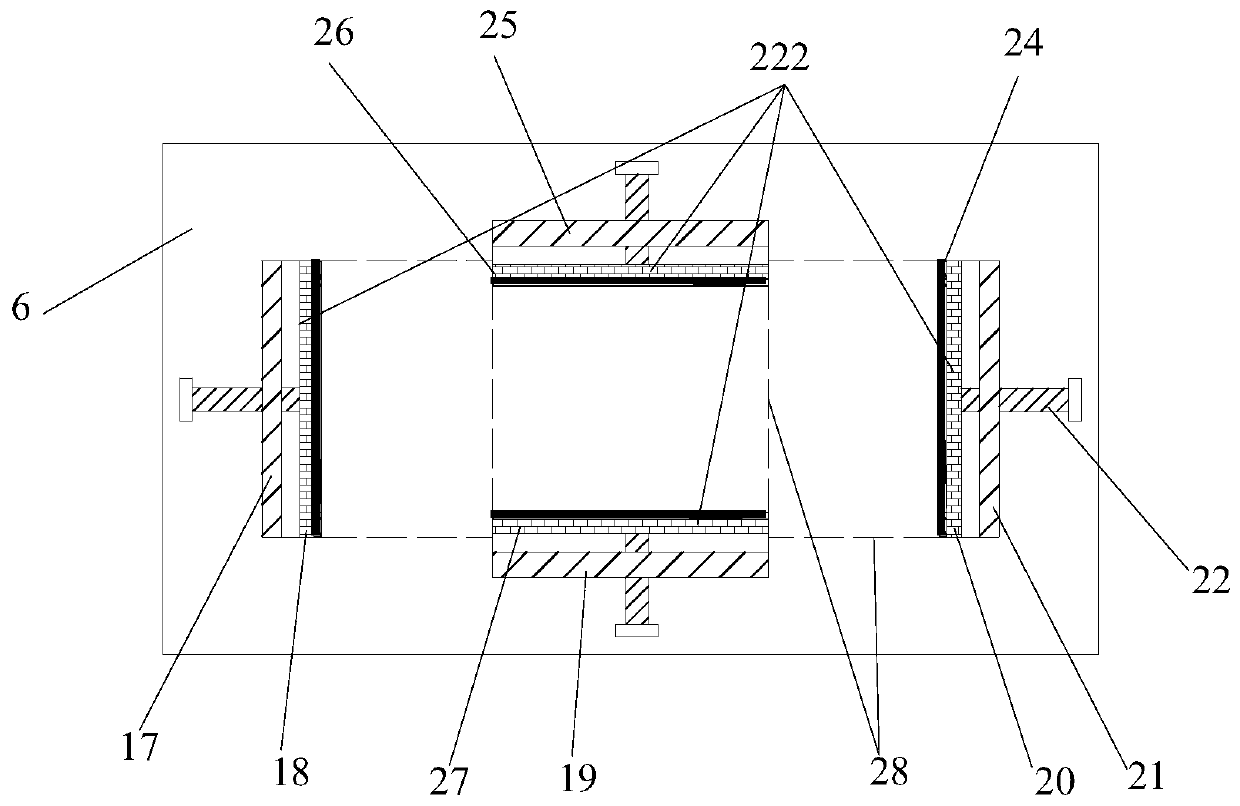

[0031] Combine Figure 1 to Figure 3 As shown, a soft rock coring device and method provided by the present invention are specifically implemented as follows.

[0032] In order to improve the efficiency and integrity of soft rock coring, maintain its original physical and mechanical properties, and provide high-precision soft rock specimens for indoor tests, the present invention provides a weakly cemented soft rock coring device and method.

[0033] Such as figure 1 As shown, a coring device for weakly cemented soft rock includes a top truss 1, a column 5, a height adjustment device 7, a base 6, a hydraulic lifting module 2, a motor module 3, a main shaft 9, a drill bit 8, and a refrigeration and dehumidification system 111 , Dust collection system (vacuum cleaner) 12, flexible transparent cover 16 and rock block fixing device 222. During the coring process, the height adjustment device 7 on the column 5 is used to adjust the height of the coring machine to match the size of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com