Automatic control device for extraction distillation and application thereof

A technology of automatic control device and controller, applied in distillation regulation/control, solvent extraction, co-current extraction, etc., can solve the problems of a large number of existing in material pipelines or condensers, difficulty in ensuring temperature stability, and high energy carried by steam , to achieve the effect of reducing labor intensity, improving extraction rate, and high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

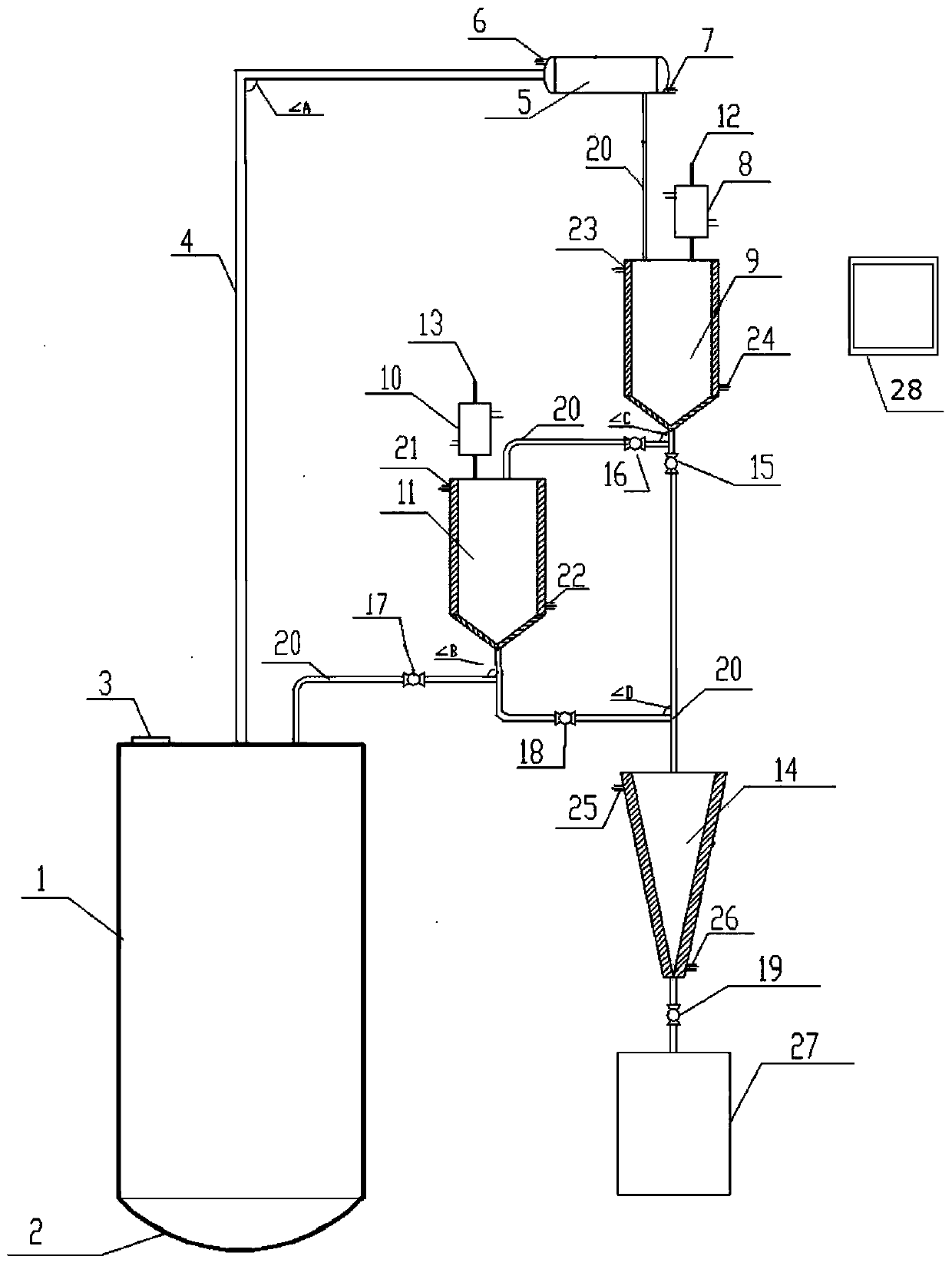

[0023] Such as figure 1 as shown, figure 1 Shown is an automatic control device for extraction and distillation provided by the present invention, which includes an extraction tank 1, a bottom cover 2, a feeding port 3, a material pipeline A4, a condensation component, an oil-water separation component, an oil collection tank 27, a controller 28, and a material pipeline B20, and series valve 15, valve 16, valve 17, valve 18, valve 19; the condensing assembly includes condenser A5, condensed water inlet A7, condensed water outlet A6, and the oil-water separation assembly includes oil-water separation assembly 1, oil-water Separation component two, oil-water separation component three, wherein the oil-water separation component one includes a condenser X8, an oil-water separator X9, an exhaust port X12, a condensed water inlet X24, and a condensed water outlet X23, and the condenser X8 is connected to the oil-water separator X9 , the top of the condenser X8 is respectively prov...

Embodiment 2

[0026] Extraction and distillation automatic control device and distillation extraction of volatile oil of Auranthus nudica

[0027] Extraction distillation automatic control device

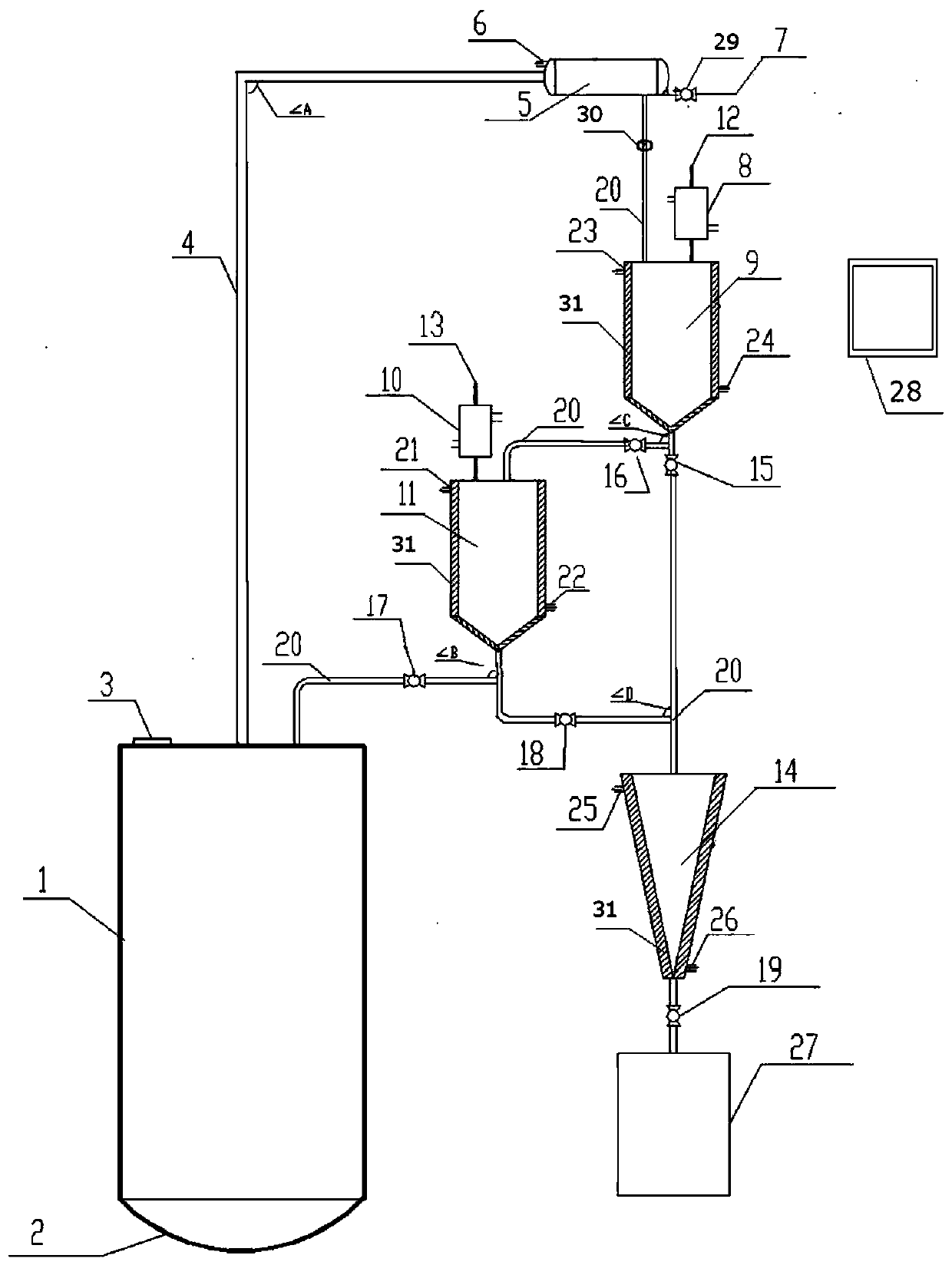

[0028] figure 2Shown is an automatic control device for extraction and distillation provided by the present invention, which includes an extraction tank 1, a bottom cover 2, a feeding port 3, a material pipeline A4, a condensation component, an oil-water separation component, an oil collection tank 27, a controller 28, and a material pipeline B20, and series valve 15, valve 16, valve 17, valve 18, valve 19; the condensing assembly includes condenser A5, condensed water inlet A7, condensed water outlet A6, and the oil-water separation assembly includes oil-water separation assembly 1, oil-water Separation component two, oil-water separation component three, wherein the oil-water separation component one includes a condenser X8, an oil-water separator X9, an exhaust port X12, a condensed water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com