Efficient crusher

A pulverizer, high-efficiency technology, applied in the direction of grain processing, etc., can solve the problems of inaccurate powder classification, affecting processing efficiency, high cost, etc., to achieve the effect of expanding the support area, improving grinding efficiency, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object and technical solutions of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments:

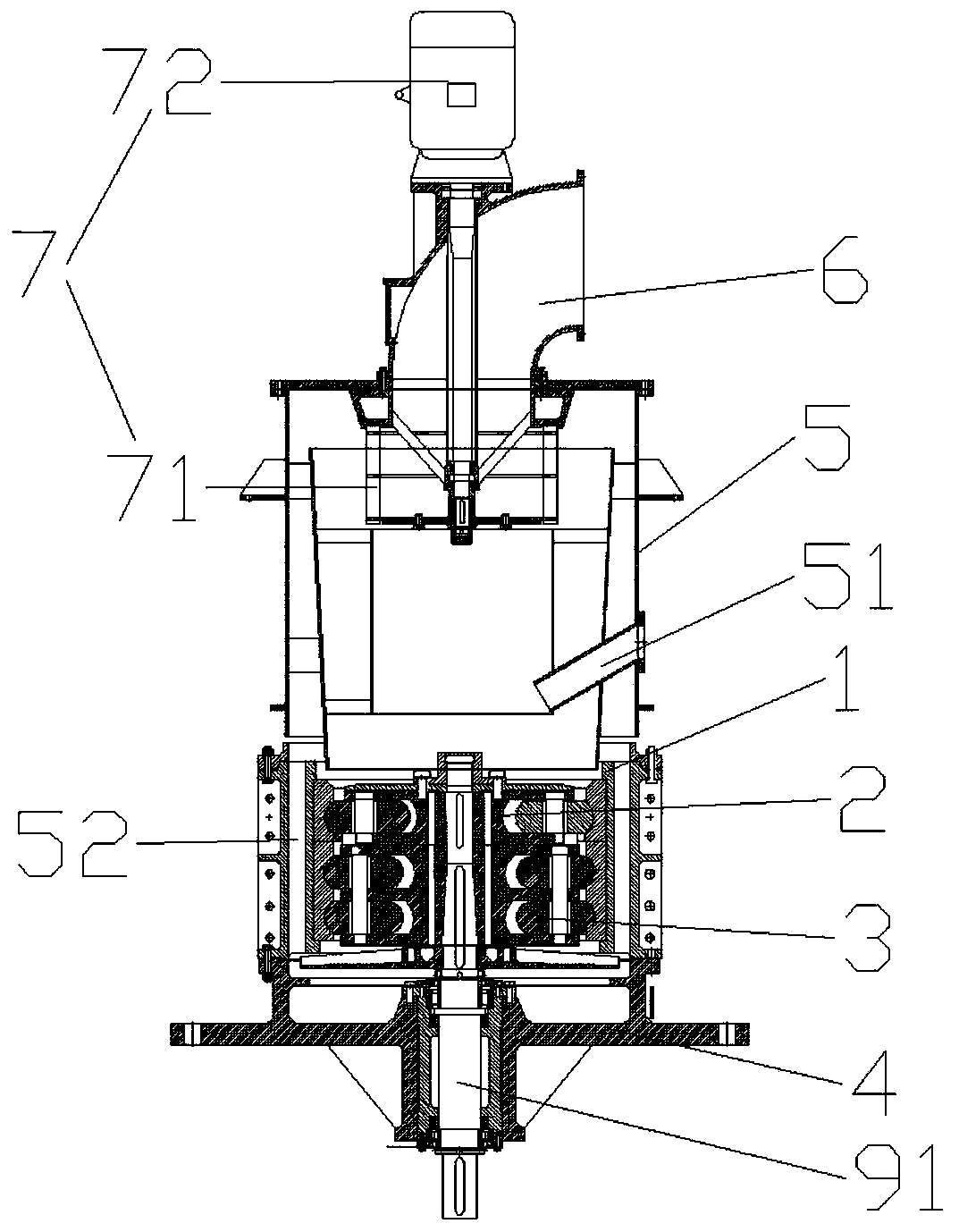

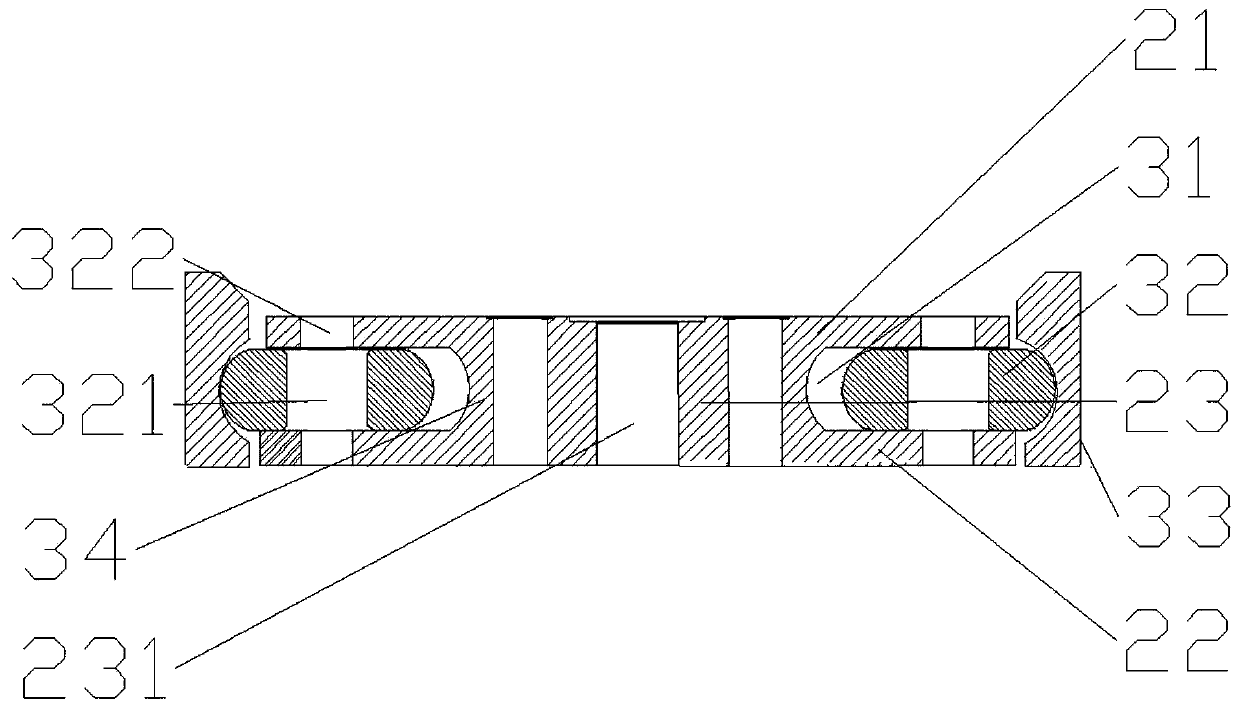

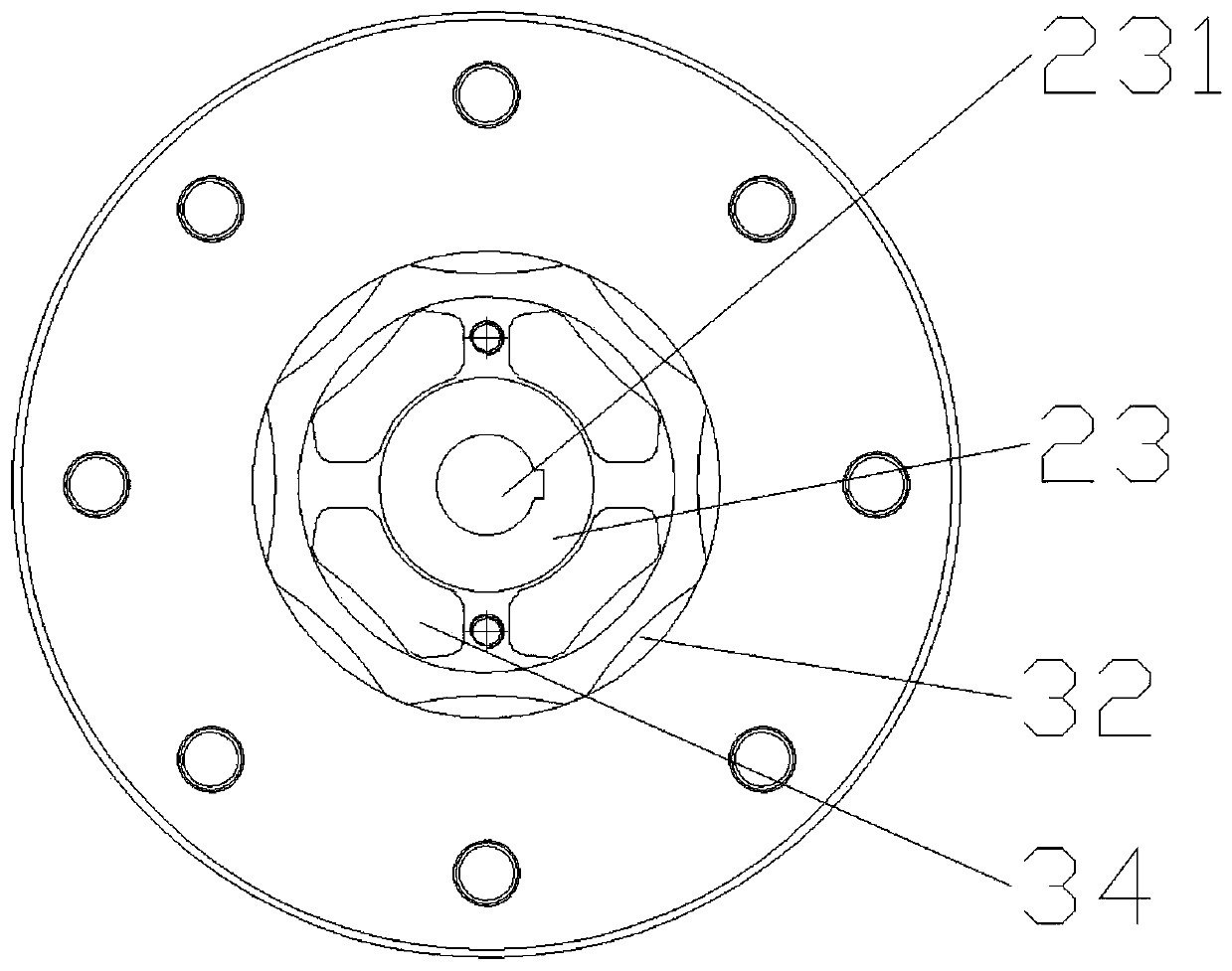

[0022] Such as Figure 1 to Figure 8 The shown high-efficiency pulverizer includes a frame 4; a housing 5, which is installed and fixed on the frame; a crushing chamber 1, which is installed inside the housing 5, and the bottom communicates with the bottom of the housing 5 The grinding wheel support 2 is disc-shaped, and is provided with an upper grinding disc 21 and a lower grinding disc 22; a central end hub 23 is provided in the middle, for connecting and fixing the upper grinding disc 21 and the lower grinding disc 22; the center of circle of the central end hub 23 The place is hollow, and runs through the center of the upper grinding disc 21 and the lower grinding disc 22 to form a transmission shaft hole 231, and the grinding wheel support 2 is installed in the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com