Room temperature vulcanized fluorosilicone rubber and preparation method thereof

A technology of fluorosilicone rubber and room temperature vulcanization, applied in the field of silicone rubber, can solve problems such as failure to meet performance requirements, increase in system viscosity, and inability to cross-link and cure, so as to improve antifouling and self-cleaning performance, improve use effect, and avoid viscosity peaks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

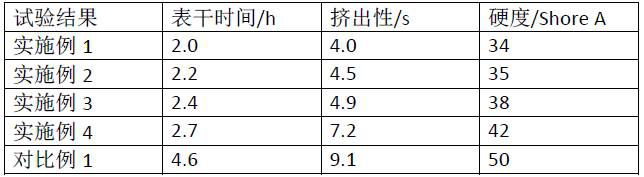

Examples

Embodiment 1

[0062] This embodiment provides a room temperature vulcanized fluorosilicone rubber and its preparation method, the steps are as follows:

[0063] (1) Preparation of methoxy-terminated fluoropolysiloxane

[0064] Mix trifluoropropyltrimethylcyclotrisiloxane, octamethylcyclotetrasiloxane and vinyl double head, then add macroporous cation exchange resin D002 to carry out polymerization reaction, after the reaction, filter and remove In addition to low-molecular reactants, vinyl-terminated fluorosilicone oil can be obtained; understandably, products with different fluorine contents can be prepared by adjusting the ratio of raw materials.

[0065] Mix the vinyl-terminated fluorosilicone oil and trimethoxyhydrogensilane, add a platinum catalyst, and carry out a hydrosilylation reaction at 65°C. The reaction time is 4h. Removal of small molecule reactants to prepare methoxy-terminated fluorine-containing polysiloxane.

[0066] (2) Prepare substrate tackifier

[0067] (3,3,3-trifl...

Embodiment 2

[0077] This embodiment provides a room temperature vulcanized fluorosilicone rubber and its preparation method, the steps are as follows:

[0078] (1) Preparation of ethoxy-terminated fluoropolysiloxane

[0079] Mix trifluoropropyltrimethylcyclotrisiloxane, octamethylcyclotetrasiloxane and vinyl double head, and then add tetramethylammonium hydroxide to carry out polymerization reaction. In addition to low-molecular reactants, vinyl-terminated fluorosilicone oil can be obtained; understandably, products with different fluorine contents can be prepared by adjusting the ratio of raw materials.

[0080] Mix the vinyl-terminated fluorosilicone oil and triethoxyhydrogensilane, add a platinum catalyst, and carry out a hydrosilylation reaction at 65°C. The reaction time is 4h. After the reaction, vacuumize, at 130°C, -0.1Mpa The small molecular reactant is removed under the condition of ethoxy-terminated fluorine-containing polysiloxane.

[0081] (2) Prepare substrate tackifier

...

Embodiment 3

[0092] This embodiment provides a room temperature vulcanized fluorosilicone rubber and its preparation method, the steps are as follows:

[0093] (1) Preparation of methoxy-terminated fluoropolysiloxane

[0094] Mix trifluoropropyltrimethylcyclotrisiloxane, octamethylcyclotetrasiloxane and vinyl double head, then add trifluoromethanesulfonic acid to carry out polymerization reaction, after the reaction, add sodium bicarbonate After neutralization, the low-molecular reactants are removed to obtain vinyl-terminated fluorosilicone oil; understandably, products with different fluorine contents can be prepared by adjusting the ratio of raw materials.

[0095] Mix the vinyl-terminated fluorosilicone oil and trimethoxyhydrogensilane, add a platinum catalyst, and carry out a hydrosilylation reaction at 65°C. The reaction time is 4h. Removal of small molecule reactants to prepare methoxy-terminated fluorine-containing polysiloxane.

[0096] (2) Prepare substrate tackifier

[0097] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com