Bilateral disassembly line setting method considering station constraints and energy consumption

A technology of energy consumption and station, which is applied in the field of bilateral disassembly line setting considering station constraints and energy consumption, to achieve the effect of reducing disassembly cost, improving disassembly efficiency and ensuring diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

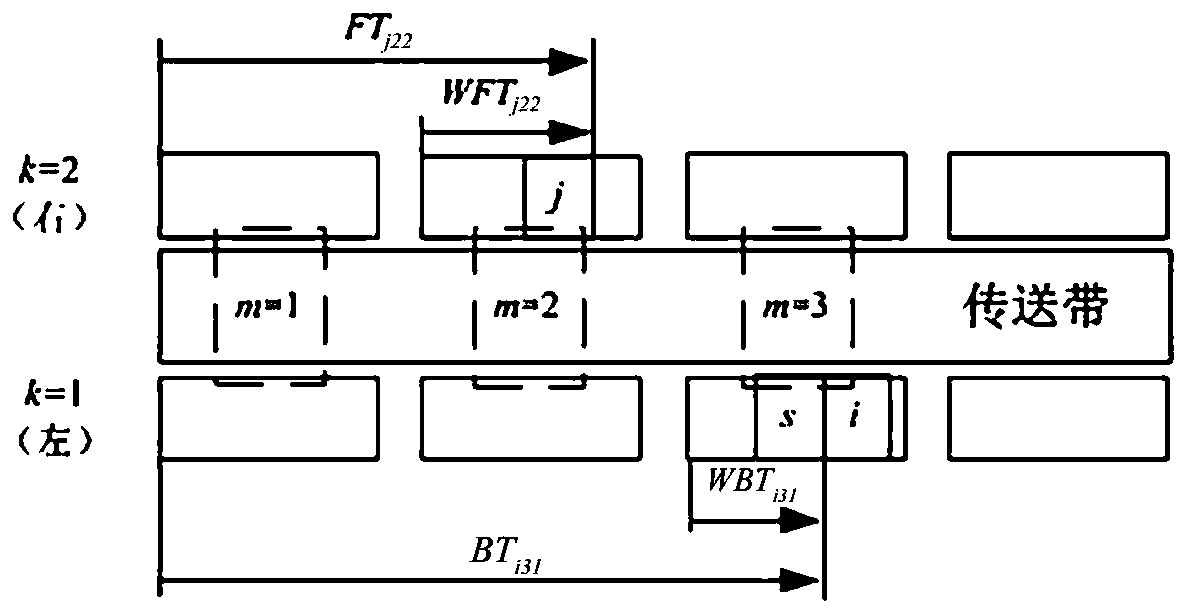

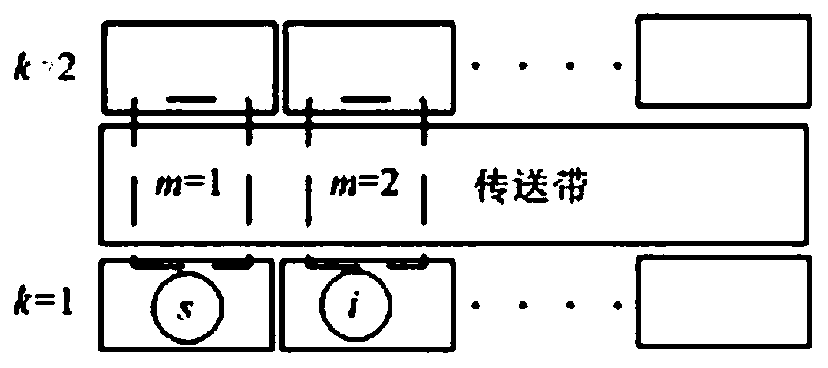

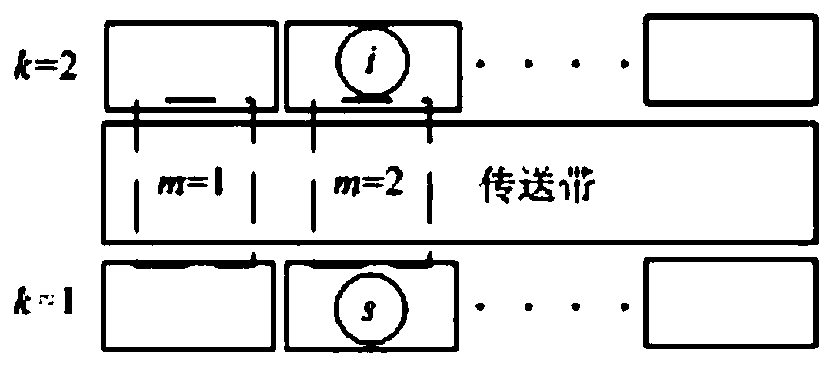

Method used

Image

Examples

Embodiment 1

[0147] The printer to be disassembled consists of 55 disassembly tasks (n=55). For the priority order of disassembly tasks, see Figure 9 , the disassembly information of the disassembly task is shown in Table 1. The disassembly information includes the disassembly time (unit is s), the required quantity (unit is piece), and the disassembly direction (1 means left side disassembly, 2 means right side disassembly, 3 means left and right can be carried out disassembly) and hazard index (0 means no hazard, 1 means hazard).

[0148] Table 1

[0149]

[0150]

[0151] The setting parameters are as follows: population size N=250, maximum number of cycles G=200, grouping rate Pam=0.4, and the capacity of external file Q is 14. according to Figure 7 The dismantling task allocation scheme obtained by the bilateral dismantling line setting method considering the station constraints and energy consumption is shown in Table 2, and the details are as follows:

[0152] Table 2

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com