Robot welding production control cabinet with high heat dissipation

A technology of robot welding and production control, which is applied to the parts of casing/cabinet/drawer, modification through conduction heat transfer, cooling/ventilation/heating transformation, etc. The effect of cooling dead angle, improving heat dissipation, and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

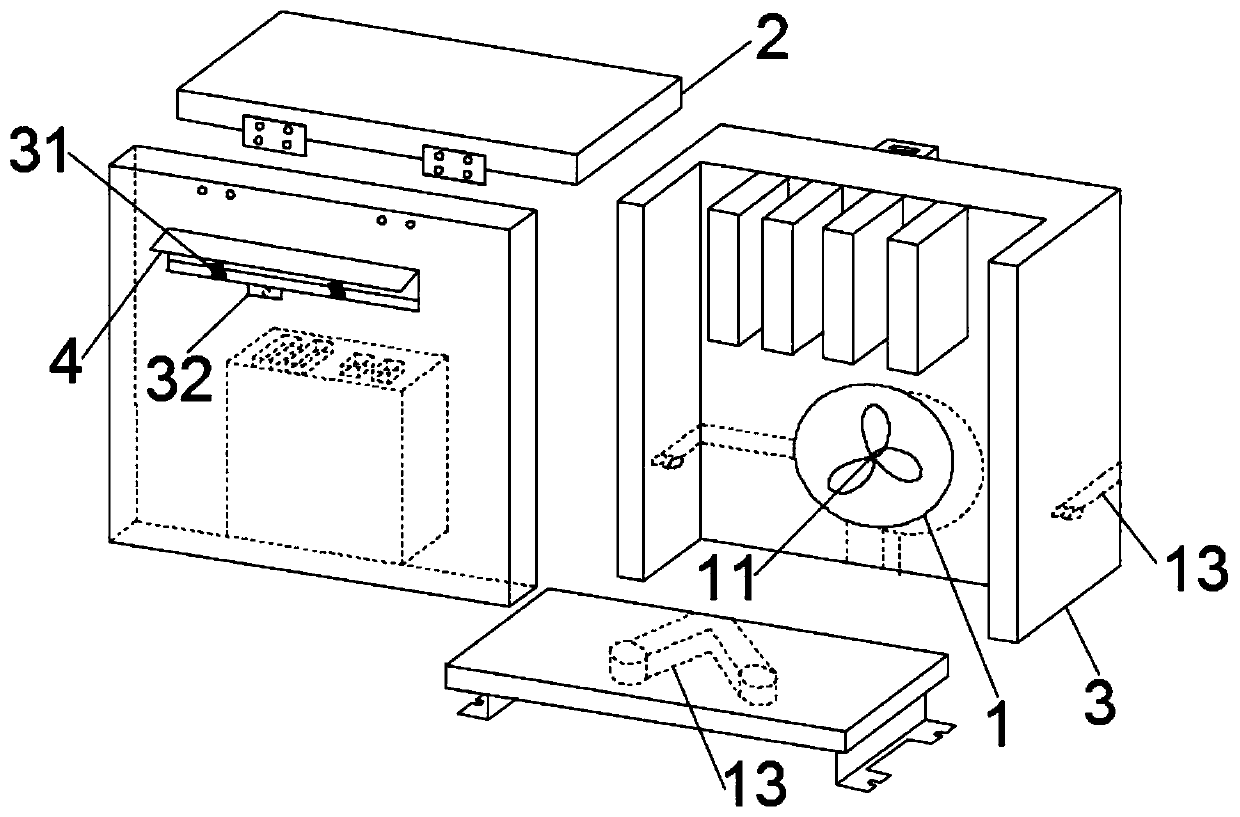

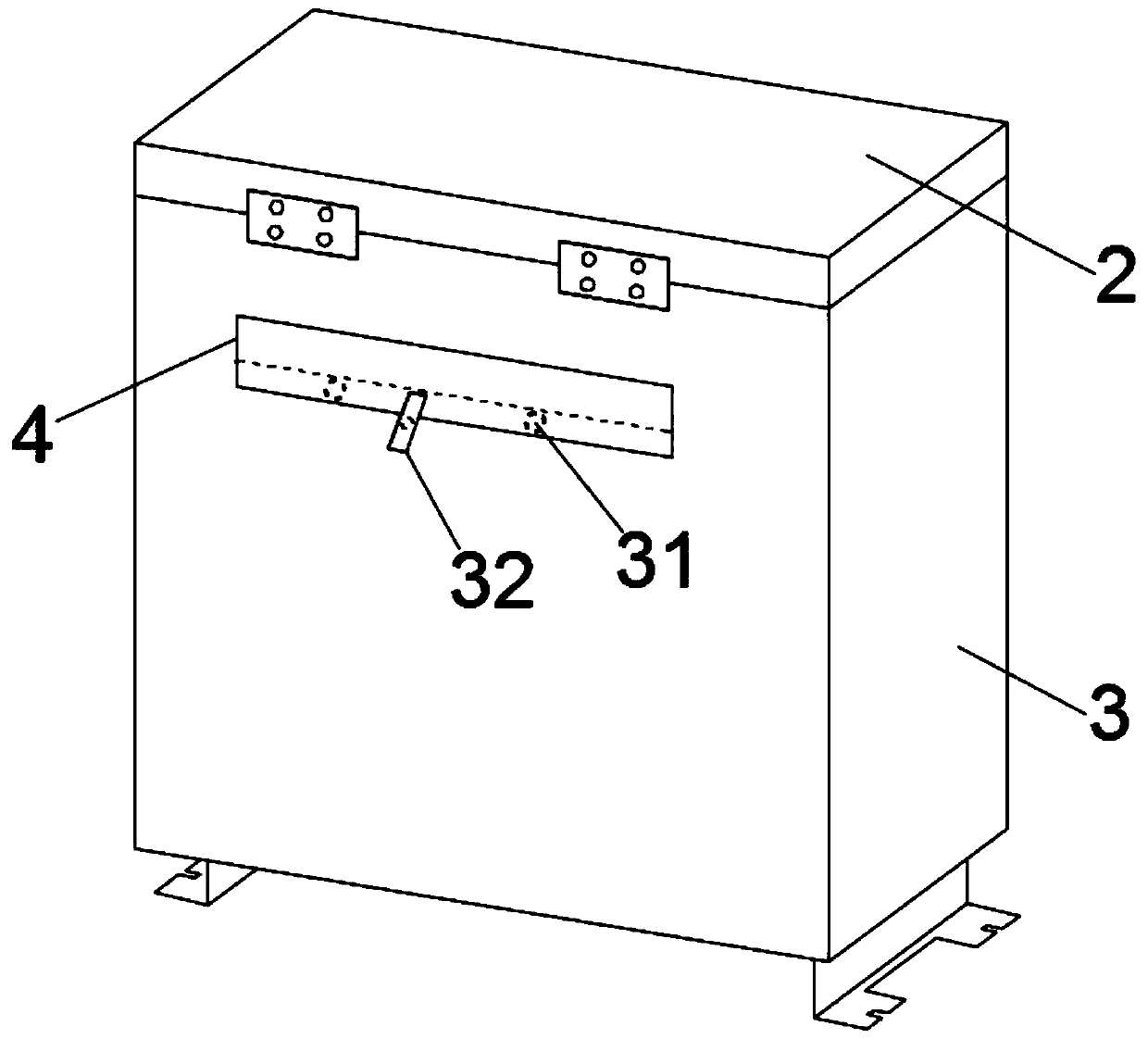

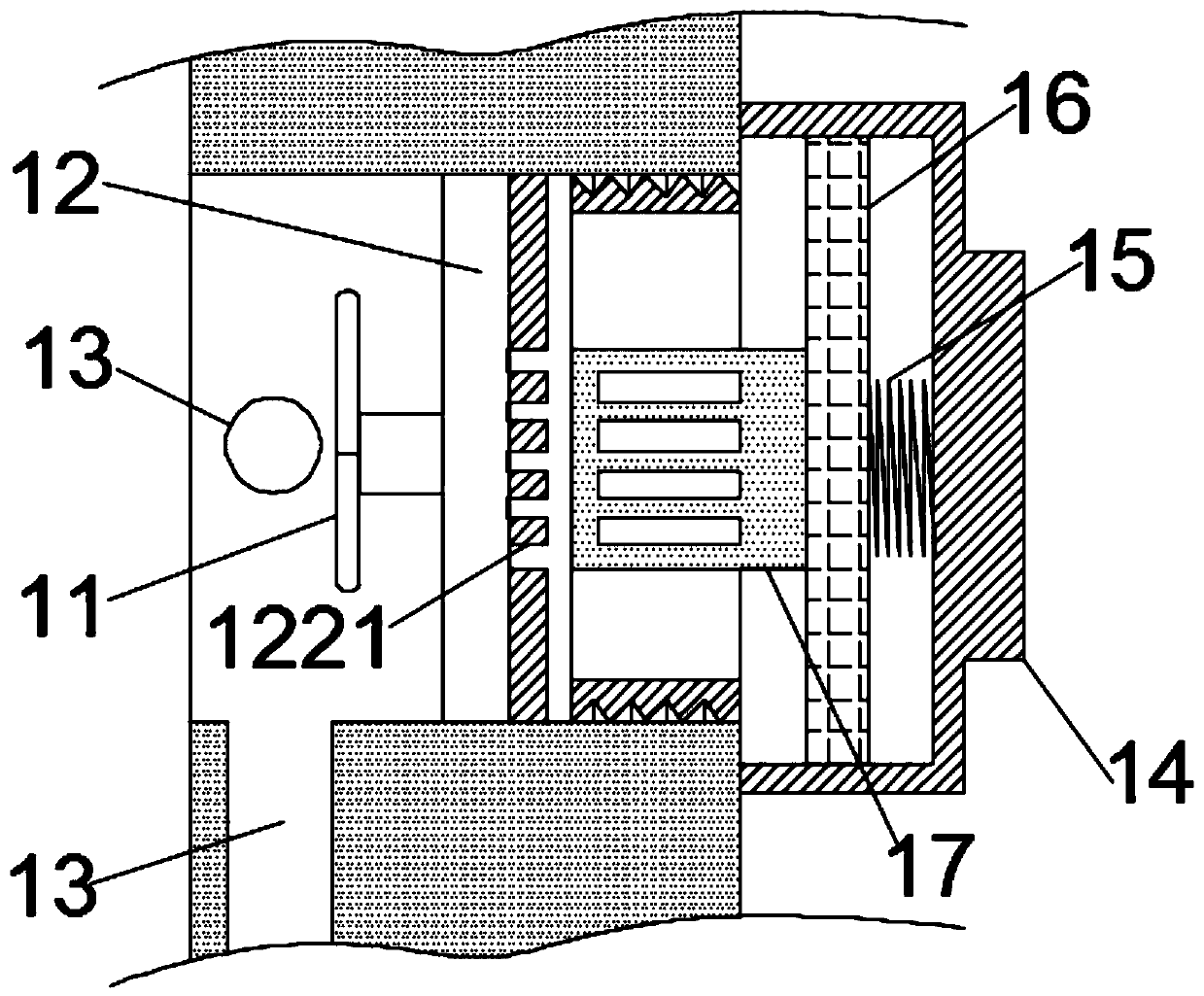

[0033] A control cabinet for robot welding production with high heat dissipation, including a sealed cabinet body and a heat dissipation mechanism 1. The sealed cabinet body is equipped with a stroke controller, a driver mounting plate and a key operation panel, and the driver mounting plate is equipped with drivers arranged in parallel. The heat dissipation mechanism 1 includes a cooling fan 11, an isolation plate 12, a fan rear cover and a ventilation duct 13, the isolation plate 12 is fixedly connected with the sealed cabinet body, the isolation plate 12 is provided with a solid rod 121 and a receiving rod 122, and the outer surface of the solid rod 121 and the receiving rod 122 The surface is coated with a heat-conducting film, the receiving rod 122 is provided with a receiving groove 1221 that matches the heat sink 171, the fan back cover is screwed to the sealed cabinet body, the ventilation duct 13 is embedded in the cabinet wall of the sealed cabinet body, and the fan ba...

Embodiment 2

[0036] A control cabinet for robot welding production with high heat dissipation, including a sealed cabinet body and a heat dissipation mechanism 1. The sealed cabinet body is equipped with a stroke controller, a driver mounting plate and a key operation panel, and the driver mounting plate is equipped with drivers arranged in parallel. The heat dissipation mechanism 1 includes cooling fan 11, isolation plate 12, fan back cover and ventilation duct 13, isolation plate 12 is fixedly connected with the sealed cabinet body, fan back cover is threaded with the sealed cabinet body, and ventilation duct 13 is embedded in the cabinet wall of the sealed cabinet body , the fan rear cover includes a main cover 14, a return spring 15, an auxiliary base 16 and a heat sink base 17, one end of the return spring 15 is fixedly connected to the main cover 14, and the other end of the return spring 15 is fixed to the auxiliary base 16 connection, the auxiliary base 16 is slidably connected with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap