Bamboo fiber/hydroxyapatite/chitosan novel composite membrane and preparation method thereof

A technology of hydroxyapatite and bamboo fiber, which is used in medical science, tissue regeneration, prosthesis, etc. to accelerate bone growth, improve mechanical properties, and prevent infection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

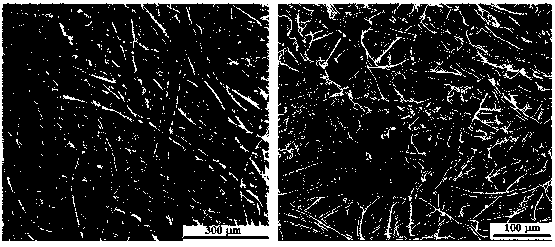

[0014] Example 1: Dissolve 1.5 g of chitosan in 80 ml of 2% glacial acetic acid to obtain a light yellow transparent mucus, add 0.3 g of nano-hydroxyapatite powder (average particle size is 30 nm) and add 20 ml of deionized water for ultrasonic After dispersing for 20 minutes, add dropwise to the chitosan solution under high-speed stirring, continue to stir at room temperature for 4 hours, add 1.0 g of surface carboxylated bamboo fibers (average length is 0.1 mm), ultrasonically disperse for 40 minutes, and continue to stir at room temperature. After stirring for 2 hours, it was left to defoam and cast on a glass plate to form a smooth dense film. The tensile strength of the composite film was 36 MPa, and the elongation at break was 25%. The film was soaked in simulated body fluid for 8 weeks, and the surface of the film was completely covered by bone-like apatite as observed by SEM; The tensile strength was 4 MPa, and the film began to lose strength by 12 weeks.

Embodiment 2

[0015] Example 2: Dissolve 1.5 g of chitosan in 60 ml of 2% glacial acetic acid to obtain light yellow transparent mucus, add 0.5 g of nano-hydroxyapatite powder (average particle size is 30 nm) and add 20 ml of deionized water for ultrasonic After dispersing for 30 minutes, add dropwise to the chitosan solution under high-speed stirring, continue to stir at room temperature for 4 hours, add 1.5 g of surface carboxylated bamboo fibers (average length is 0.1 mm), ultrasonically disperse for 1 hour, and continue to stir at room temperature. After stirring for 2.5 hours, it was left to defoam and cast on a glass plate to form a smooth dense film. The tensile strength of the composite film was 52 MPa, and the elongation at break was 28%. The film was immersed in simulated body fluid for 8 weeks, and its surface was completely covered by bone-like apatite as observed by SEM; the immersion continued until 10 weeks , the tensile strength of the film was 10 MPa, and the film began to ...

Embodiment 3

[0016] Example 3: Dissolve 1.2 g of chitosan in 50 ml of 2% glacial acetic acid to obtain light yellow transparent mucus, add 0.8 g of nano-hydroxyapatite powder (average particle size is 30 nm) and add 25 ml of deionized water for ultrasonic After dispersing for 30 minutes, add dropwise to the chitosan solution under high-speed stirring, continue to stir at room temperature for 4 hours, add 1.0 g of surface carboxylated bamboo fibers (average length is 0.1 mm), ultrasonically disperse for 1 hour, and continue to stir at room temperature. After stirring for 3 hours, it was left to defoam and cast on a glass plate to form a smooth dense film. The tensile strength of the composite film is 48 MPa, and the elongation at break is 26%. The film is immersed in simulated body fluid for 8 weeks, and its surface has been completely covered by bone-like apatite as observed by SEM; the immersion lasts until the immersion lasts for 10 weeks , the tensile strength of the film was 6 MPa, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap