Composite manufacturing process of multi-layer stainless steel composite pot

A manufacturing process and technology for compound pots, applied in the field of compound pots, can solve the problems of poor heat distribution of iron enamel pots, poor heat distribution of stainless steel pots, and poor heat distribution of iron pots, achieving superior performance and reducing work energy consumption , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

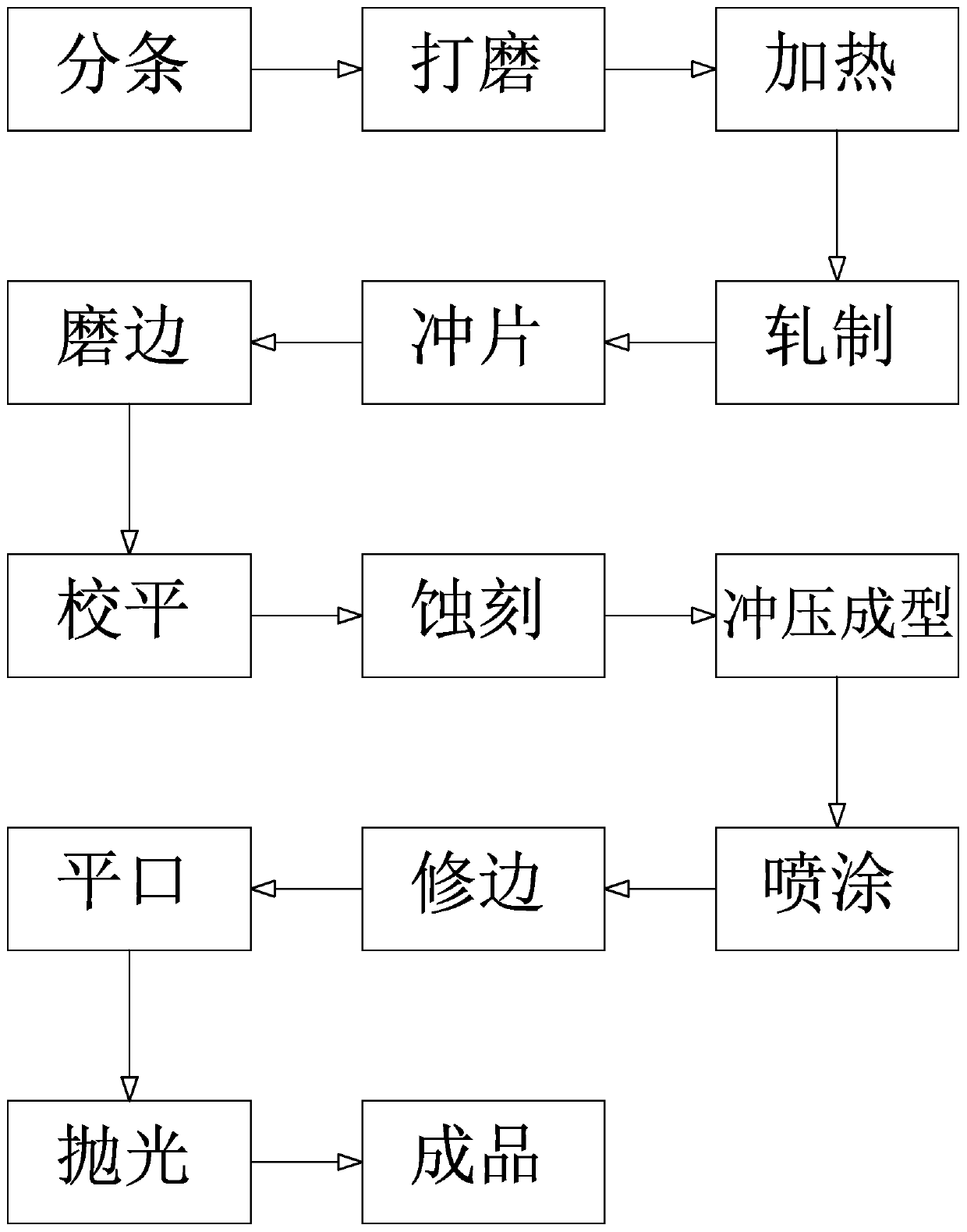

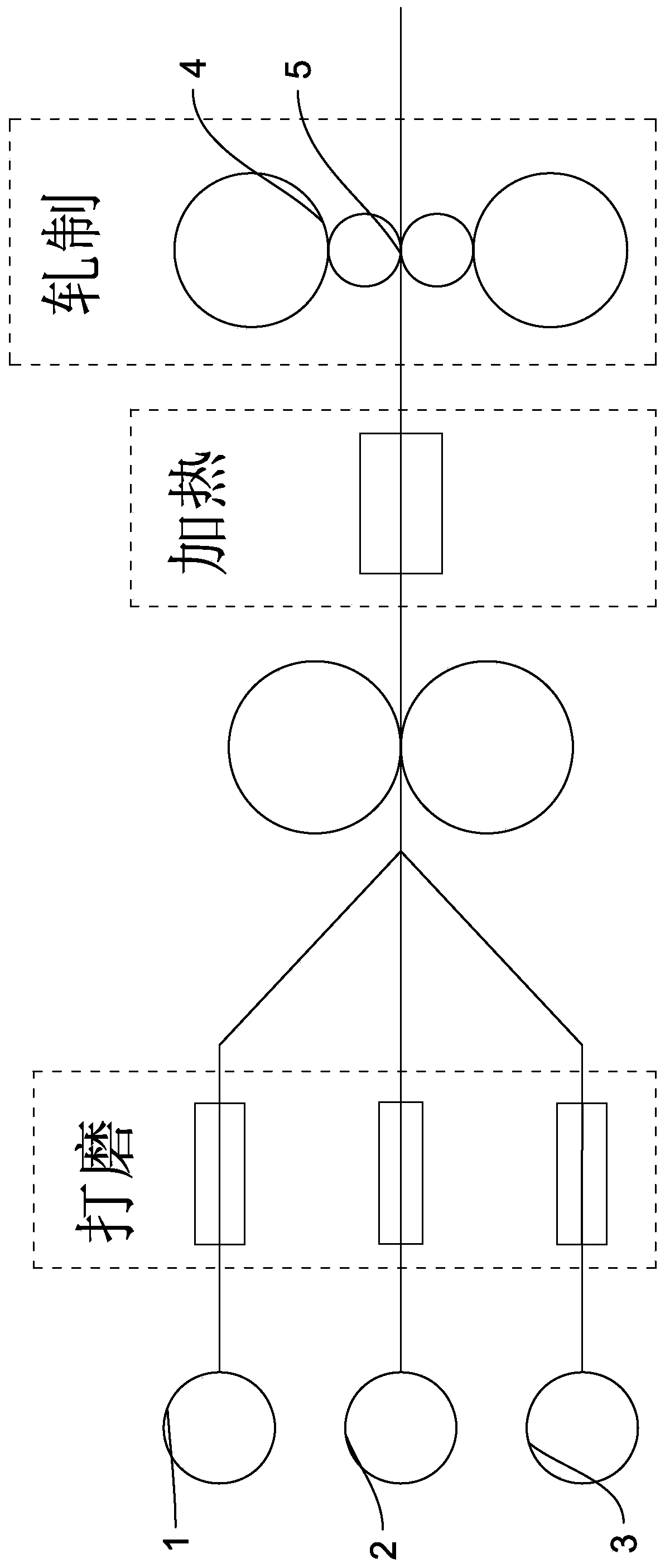

[0034] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 -2:

[0035] The composite manufacturing process of the multi-layer 304 stainless steel composite pot includes at least three layers, and the upper and lower layers are successively 304 stainless steel layer 1, aluminum layer 2, and 304 stainless steel layer 1. The multi-layer composite plate formed by rolling and compounding, the multi-layer composite plate The rolling process includes the following steps:

[0036] In step a, the 304 stainless steel sheet, the aluminum sheet, and the 430 stainless steel sheet are carried out into strips;

[0037] Step b, carrying out surface pretreatment to the 304 stainless steel sheet, the aluminum sheet, and the 430 stainless steel sheet in step a;

[0038] Step c: heating the 304 stainless steel sheet, the aluminum sheet, and the 430 stainless steel sheet in step b;

[0039] Step d: Arrange the 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com