Novel linear friction welding device

A new type of linear friction welding technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of increased energy consumption, high requirements for external devices, expensive linear friction welding equipment, etc., to achieve increased Reciprocating motion frequency, reduction of driving force, and effect of preventing misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

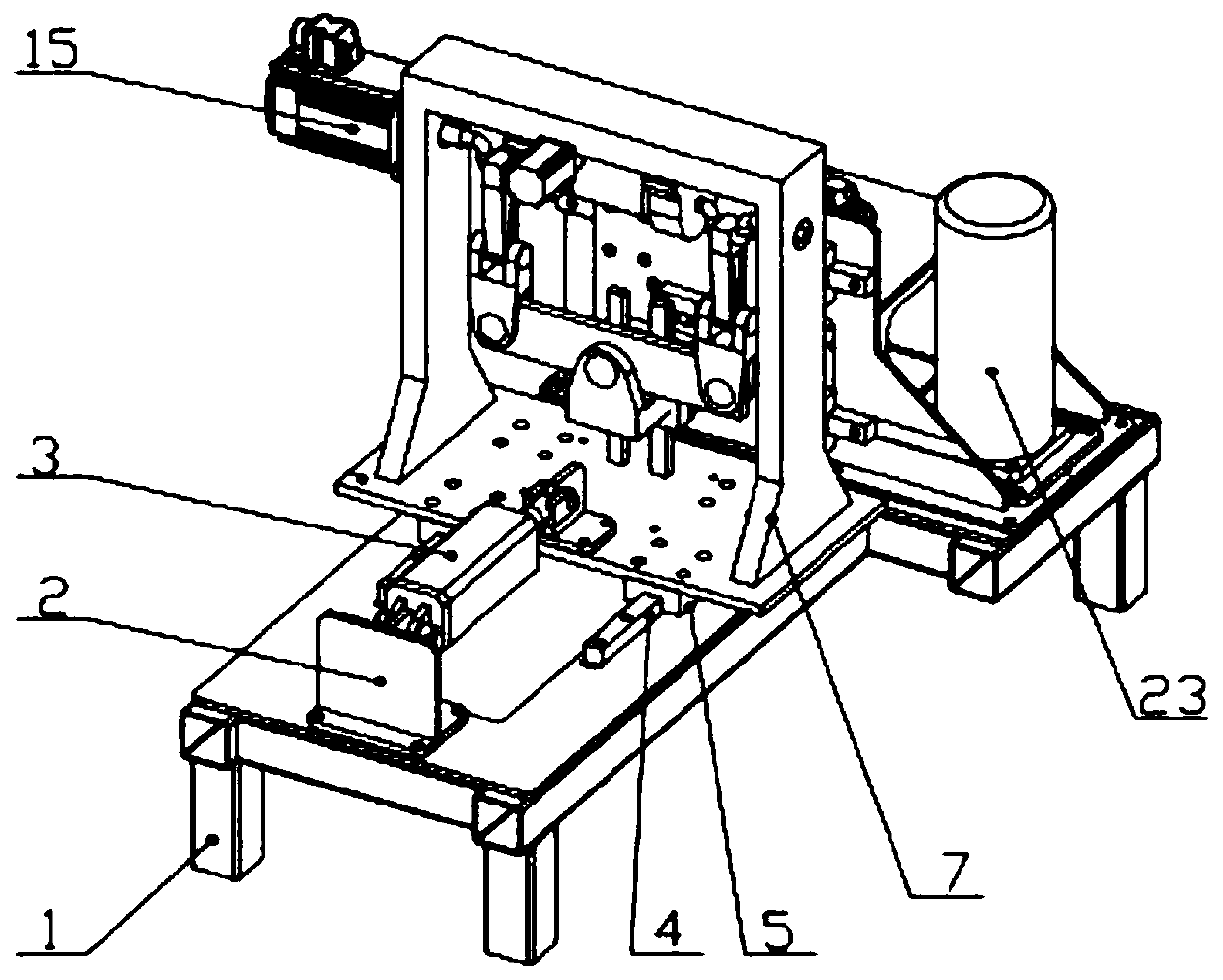

[0021] Specific embodiments of the present invention such as Figure 1 to Figure 6 As shown, a new type of linear friction welding device includes a base 1 and a support frame 7, and the support frame 7 is movably arranged on the upper end surface of the base 1; it is characterized in that it includes a vibration mechanism, a double cam mechanism and a feed mechanism;

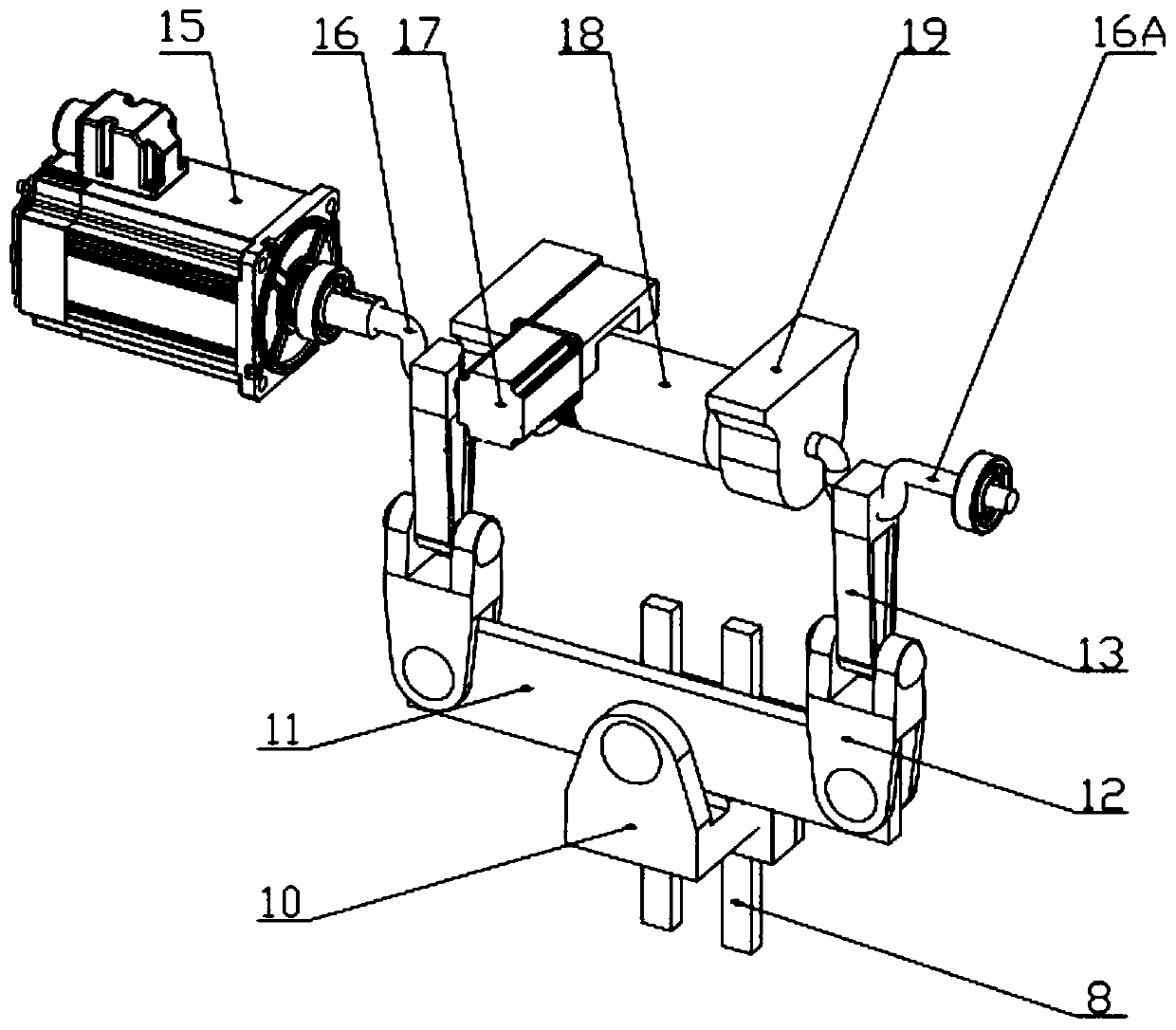

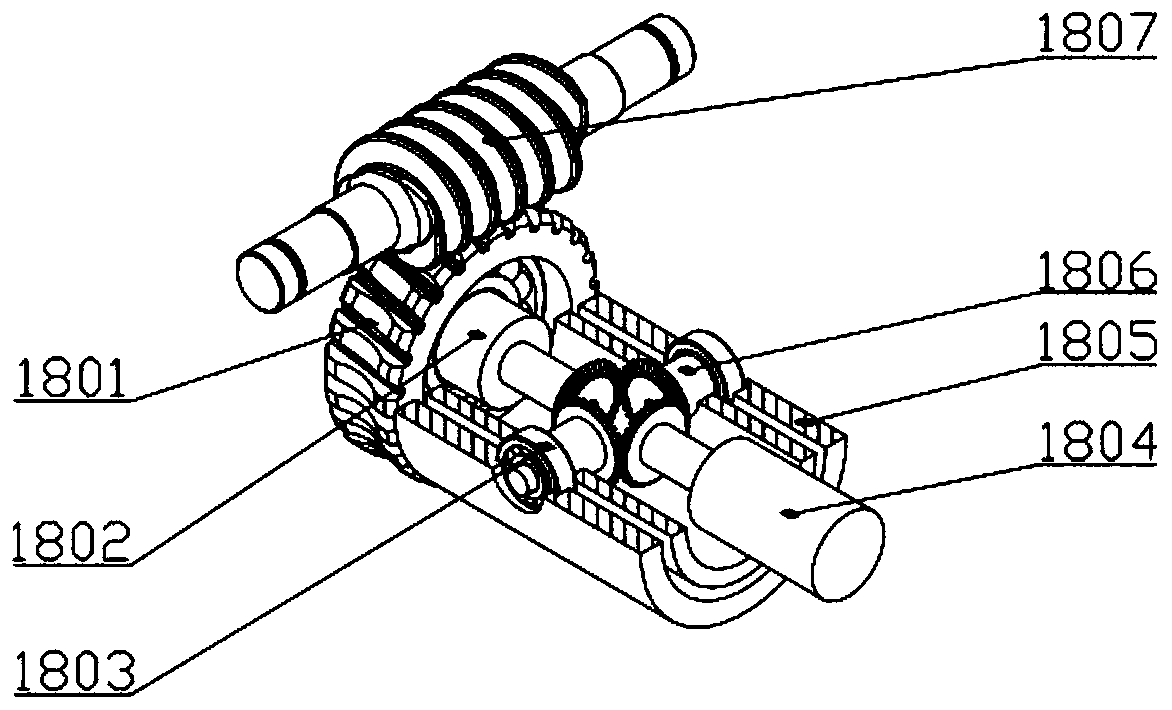

[0022] Described vibration mechanism is arranged on support frame 7, and described vibration mechanism comprises crankshaft drive motor 15, phase change mechanism, vertical slide rail 8, vertical slider 9, steering joint 10, crossbeam 11, two connectors 12, Two connecting rods 13, two crank shafts 16 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com