Multi-roller square paper cup knurling mechanism

A knurling and square technology, applied in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of slow production speed, precision discount, short service life, etc., to improve knurling production speed and ensure knurling quality , the effect of fewer moving parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

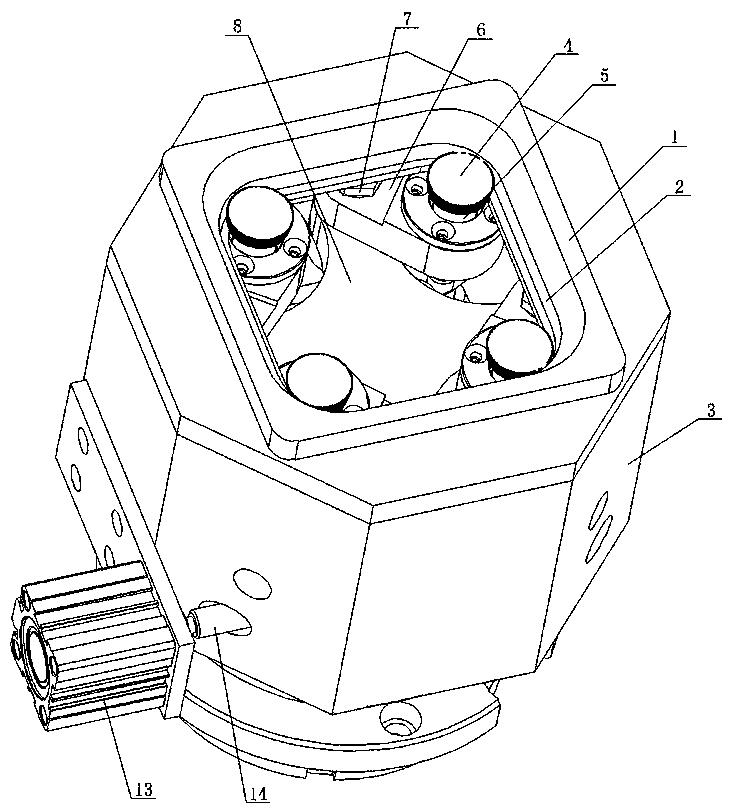

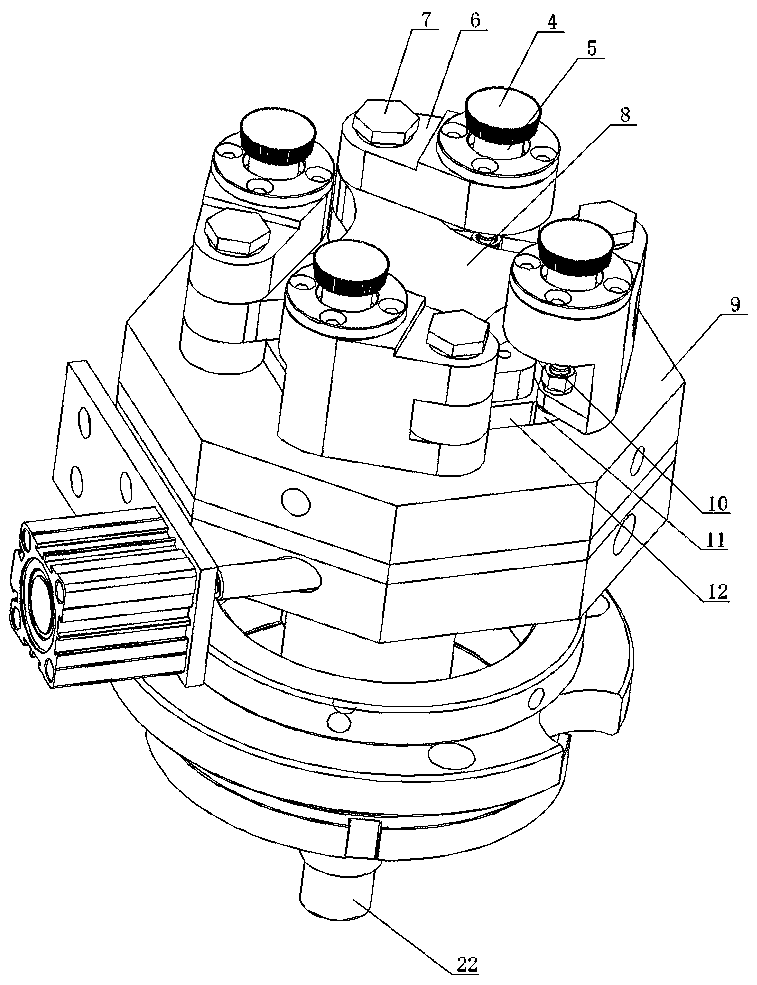

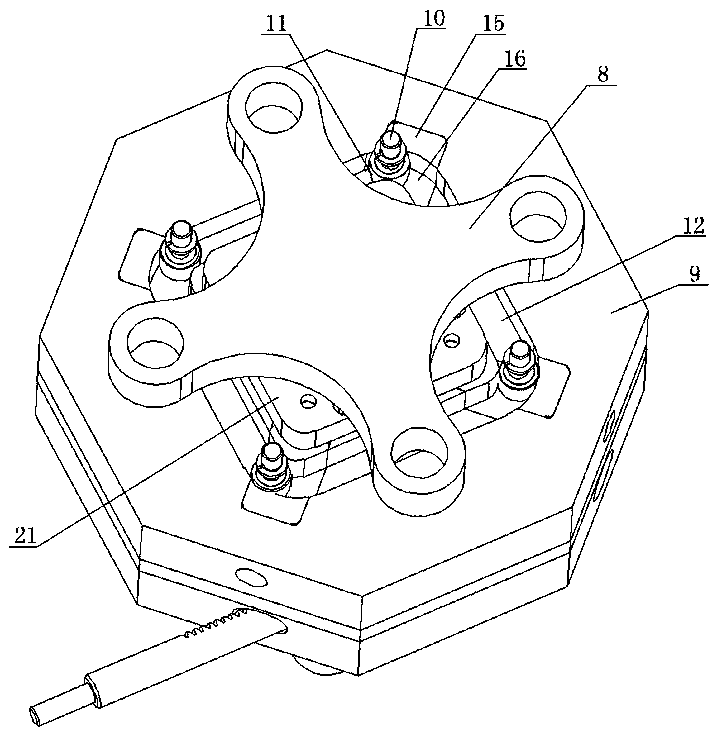

[0018] As shown in the figure, the multi-roller square paper cup knurling mechanism of the present invention includes a knurling sleeve 1 and a knurling wheel 4. The knurling sleeve 1 is fixedly connected to the upper part of the knurling seat 3, and the knurling sleeve 1 has a regular quadrilateral square shape. The inner cavity 2, the knurling wheel 4 is set in the square inner cavity 2, there are four knurling wheels 4, and the four knurling wheels 4 correspond to the four sides of the square inner cavity 2 respectively, and the knurling wheel 4 is connected to the vertical axle 5 On the bottom of the knurling wheel 4, there is a guide roller 11 coaxial with the knurling wheel 4. The guide roller 11 rolls in the cam groove 12, the cam groove 12 is opened on the cam disc 9, and the cam disc 9 is fixed on the In the knurling seat 3, the cam groove 12 is also a regular quadrilateral, and the cam groove 12 keeps the same distance between the knurling wheel 4 and the square inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com