Single-roller square cup knurling mechanism

A single-roller, knurling technology, which is applied in container manufacturing machinery, paper/cardboard containers, box production operations, etc., can solve the problems of short service life, difficult cup bottom knurling, increased processing and assembly difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

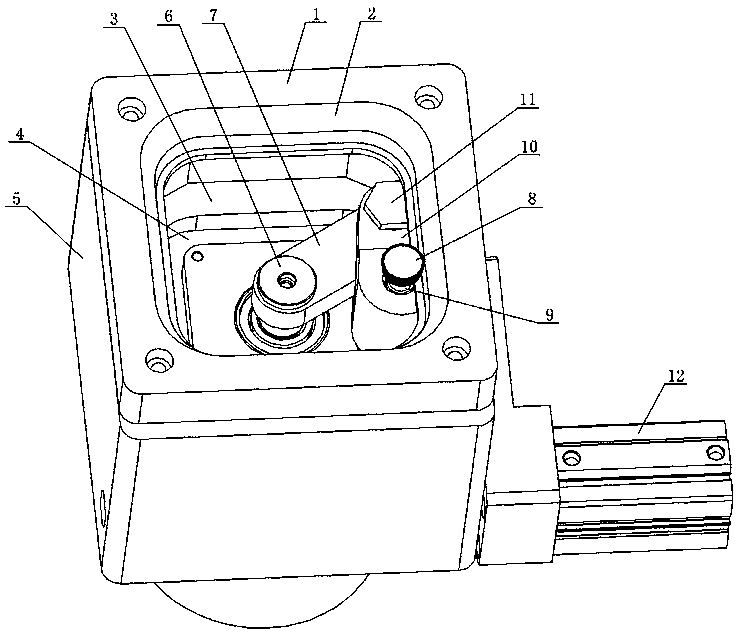

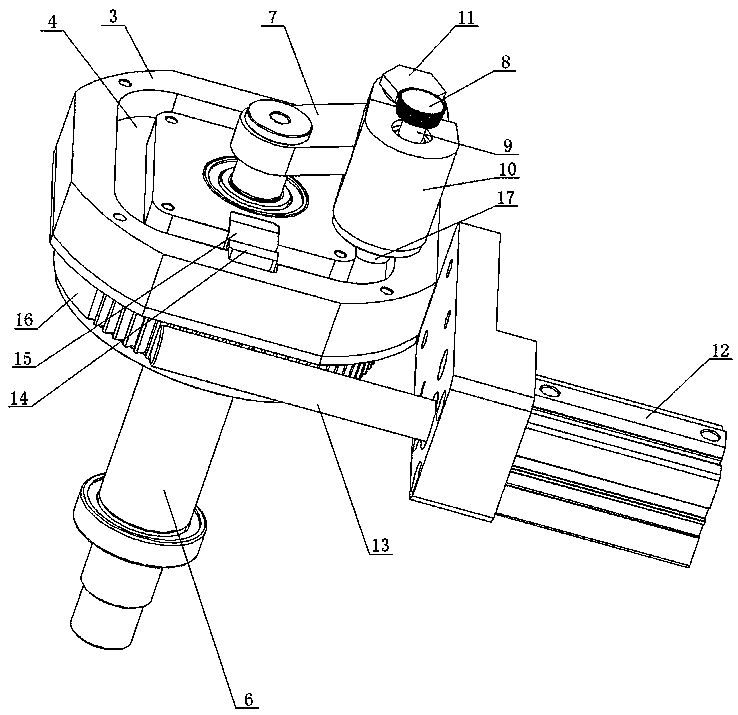

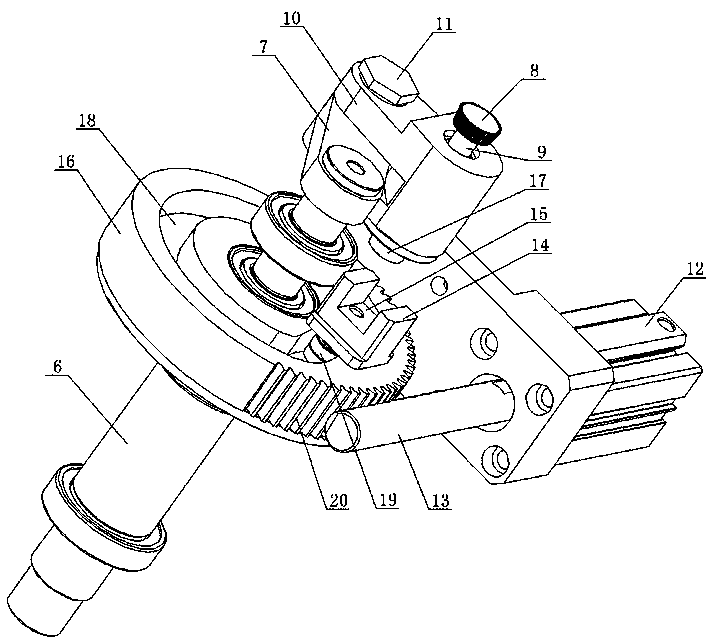

[0014] As shown in the figure, the single-roller square cup knurling mechanism of the present invention includes a knurling sleeve 1 and a knurling wheel 8, the knurling sleeve 1 is fixedly connected to the upper part of the knurling seat 5, and the knurling sleeve 1 has a square inner cavity 2 , the knurling wheel 8 is movable in the square inner cavity 2, the knurling wheel 8 is connected to the upper shaft end of the vertical wheel shaft 9, the lower shaft end of the vertical wheel shaft 9 is connected to the guide roller 17, and the guide roller 17 is rolled on the cam groove 4 Inside, the cam groove 4 is opened on the cam plate 3, the cam plate 3 is fixed in the knurling seat 5, the cam groove 4 is also square, and the cam groove 4 makes the knurling wheel 8 and the square shape of the knurling sleeve 1 during knurling work. The same distance is always maintained between the walls of the inner cavity 2, the vertical axle 9 is installed on the crank 10, the crank 10 is hing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com