Multipurpose tray

A multi-purpose, tray technology, applied in the direction of rigid containers, containers, packaging, etc., can solve the problem of low applicability, and achieve the effect of simple structure, avoiding scratches, and avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

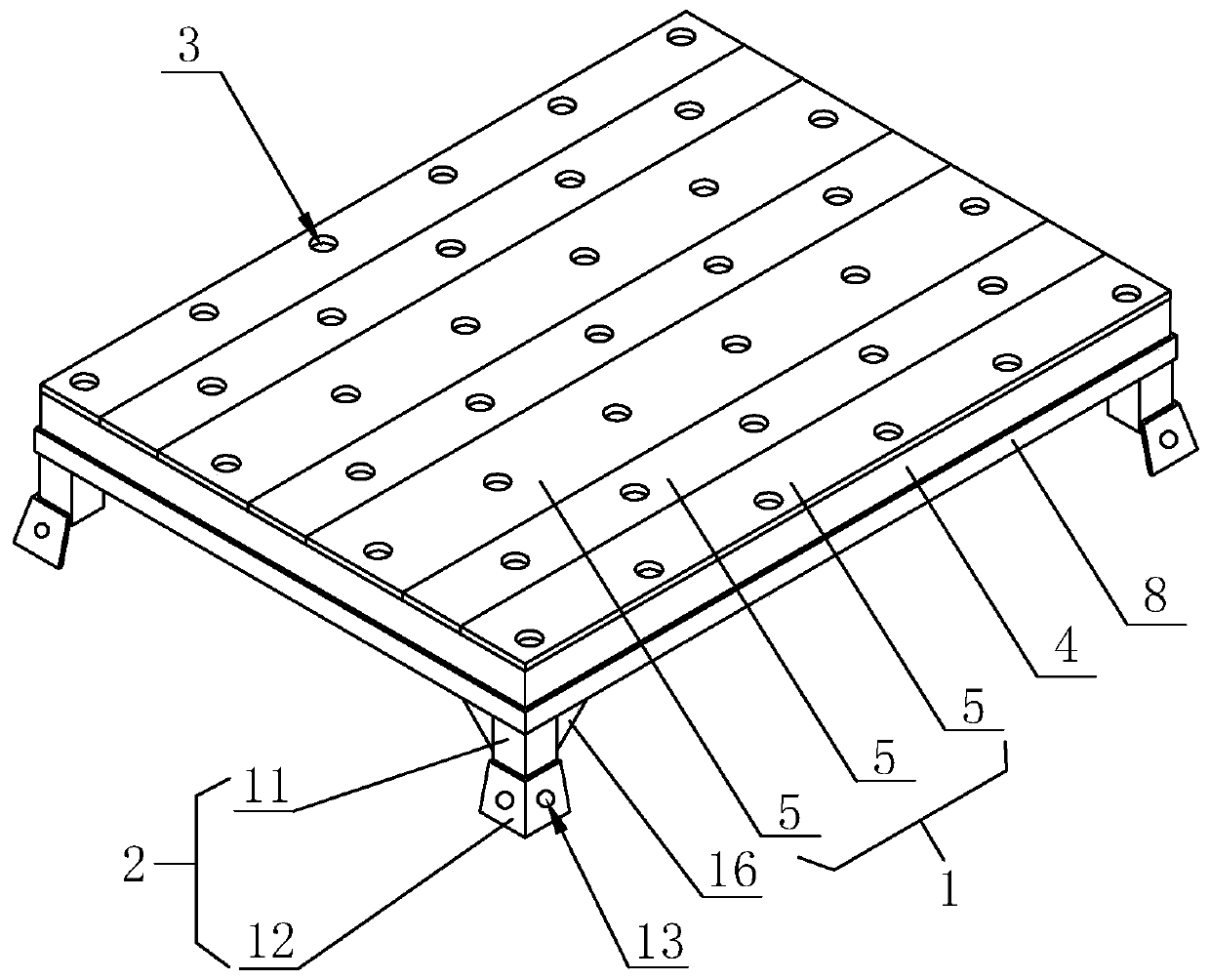

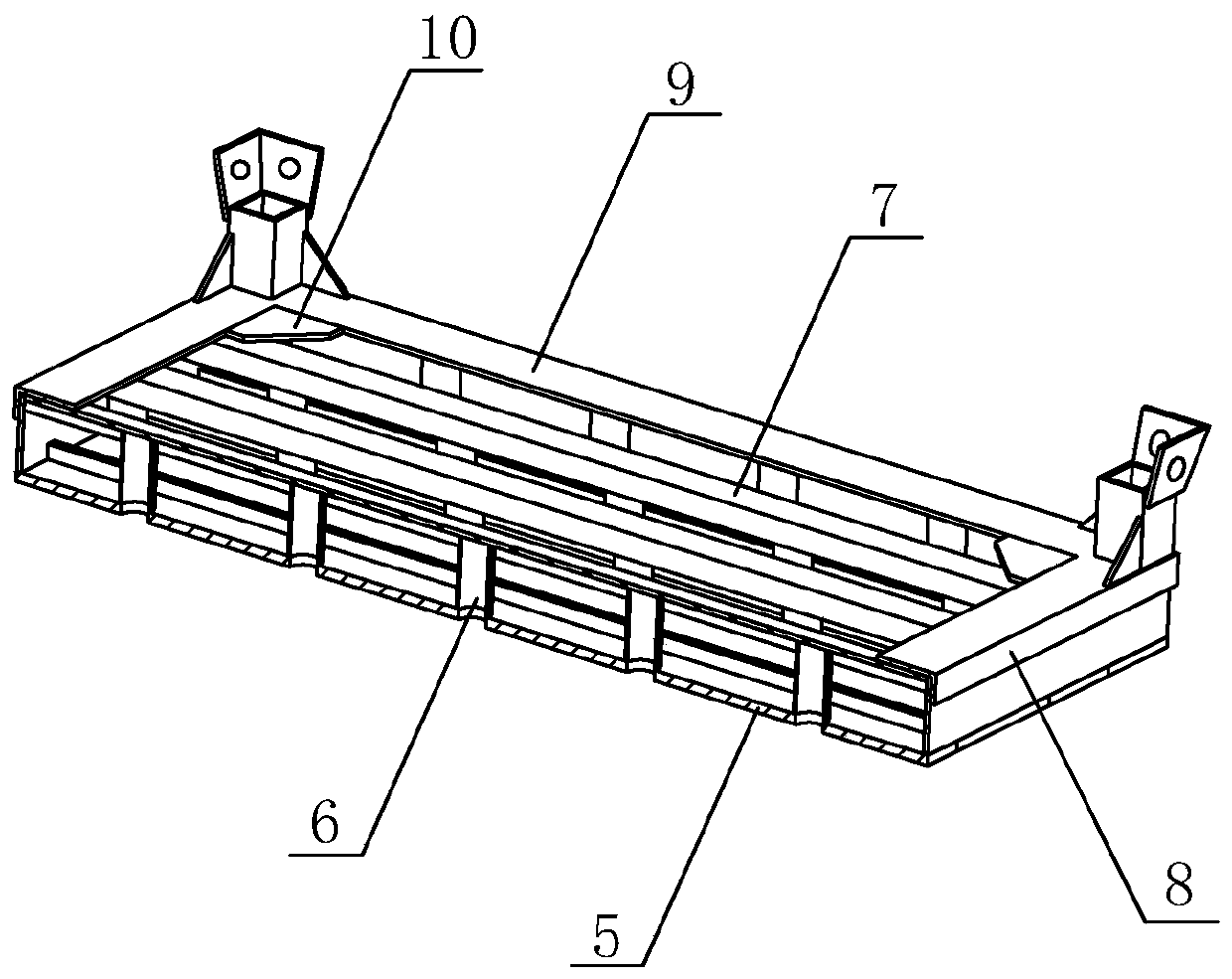

[0057] A multi-purpose pallet such as figure 1 and image 3As shown, it includes a supporting plate 1, and a plurality of supporting feet 2 for supporting are arranged on one side of the supporting plate 1. The supporting plate 1 includes a rectangular or square-shaped surrounding plate 4, and the surrounding plate 4 is composed of four vertically placed plate It is welded and fixed by gold head and tail. There are multiple plate surfaces 5 welded and fixed in parallel on one side of the coaming plate 4. The plate surfaces 5 are spliced from the leftover materials of the parts. It is green and environmentally friendly, reducing resource waste, and the splicing adopts hemming , to increase the bearing strength of the board surface 5 . A protective layer is fixed on the surface of the board, and the protective layer is a wood or plastic board, which is fixed on the board by screws or bolts to protect the product. A plurality of blind holes 3 are arranged on the board surface...

Embodiment 2

[0063] A multi-purpose pallet such as Figure 5 As shown, the difference from Embodiment 1 is that the blind holes 3 on both sides of the supporting plate 1 and the blind holes 3 on the middle plate 5 are alternately arranged, and the middle plate 5 adopts the same plate surface. 5. It is convenient to realize standardized processing and production.

Embodiment 3

[0065] A multi-purpose pallet such as Figure 6 As shown, the difference from the third embodiment is that the length direction of the U-shaped plate 7 is set perpendicularly to the length direction of the plate surface 5, and a plurality of plate surfaces 5 are arranged parallel to each other between the coaming plates 4, and the U-shaped The plate 7 is arranged perpendicular to the plate surface 5, and the U-shaped plate 7 connects a plurality of plate surfaces 5 in the width direction of the plate surface 5, which further enhances the structural strength of the present invention.

[0066] In summary:

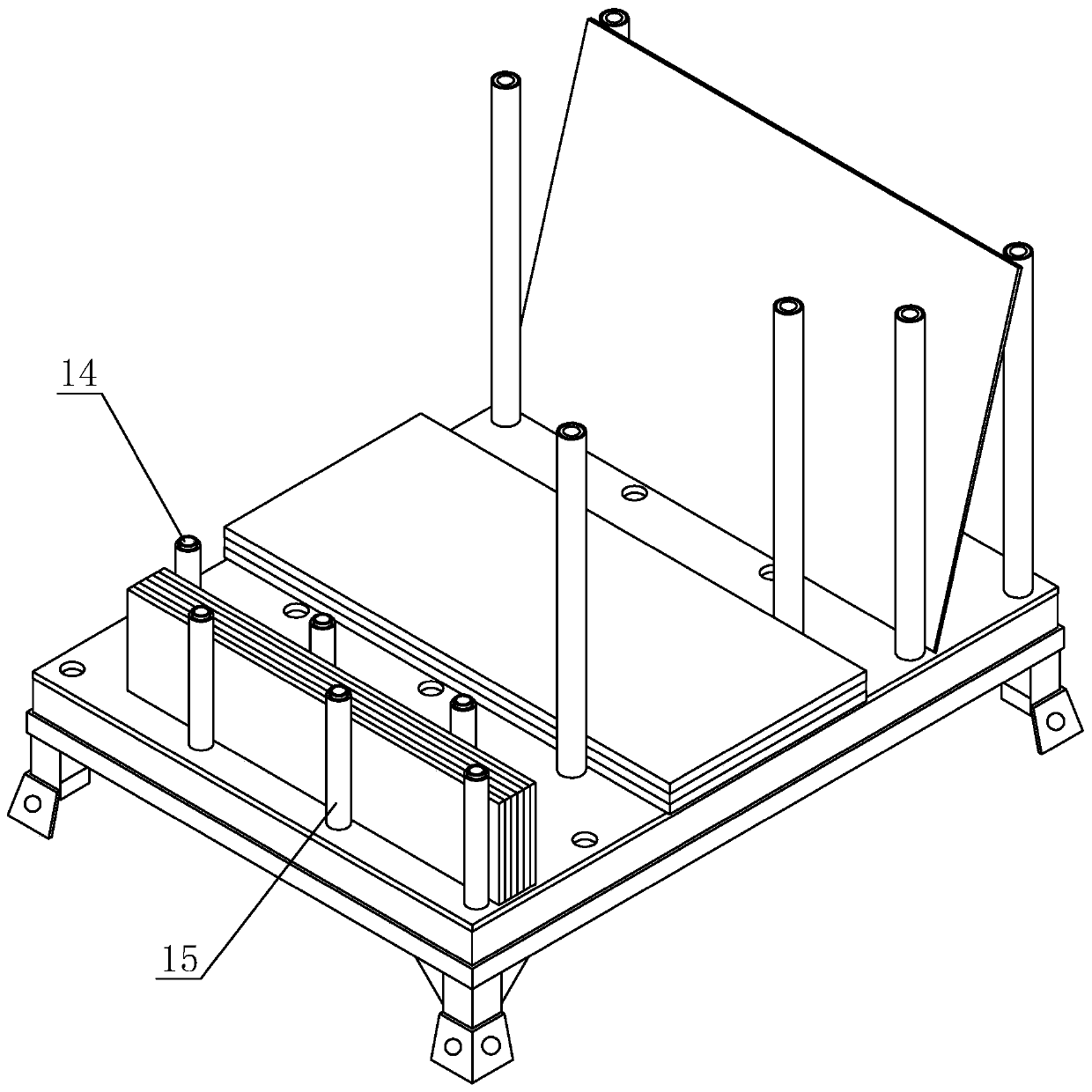

[0067] When the present invention is used, by setting the blind hole 3 on the board surface 5, it is convenient to insert round rods on the board surface 5, and adapt to multi-variety, multi-batch, small-batch, large-batch, and non-standard products in various placement ways. Parts, strong applicability; through the intubation 6, the plate surface 5 and the U-shaped plate 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com