Rubber composition and conductive roller using the same

A rubber composition, a technology of a conductive roller, applied in the direction of the electric recording process applying the charge pattern, the conductive paint, the equipment of the electric recording process applying the charge pattern, etc. problems such as degradation of stability, and achieve the effect of excellent image durability and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

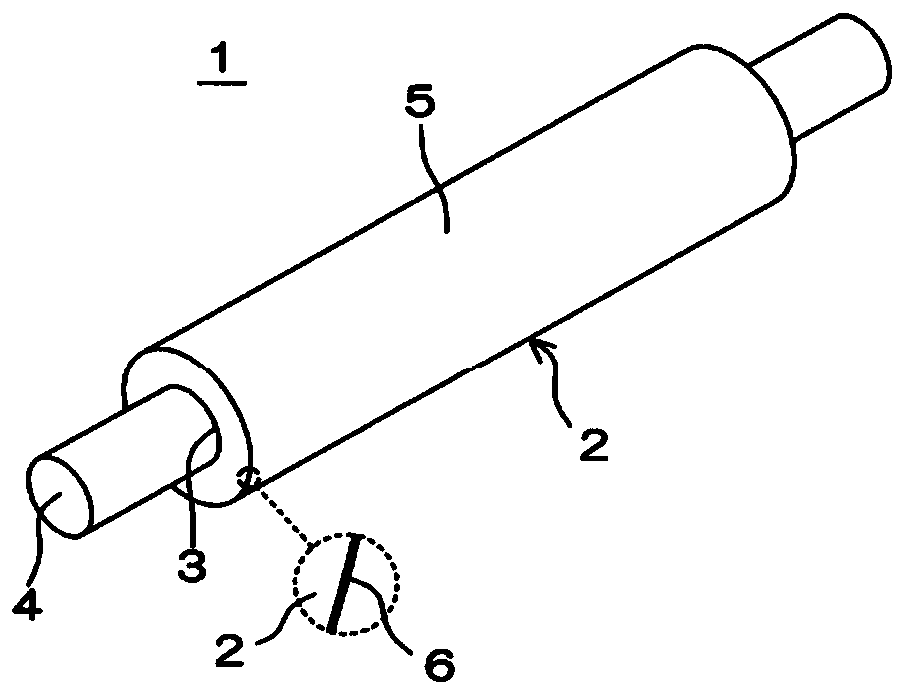

Image

Examples

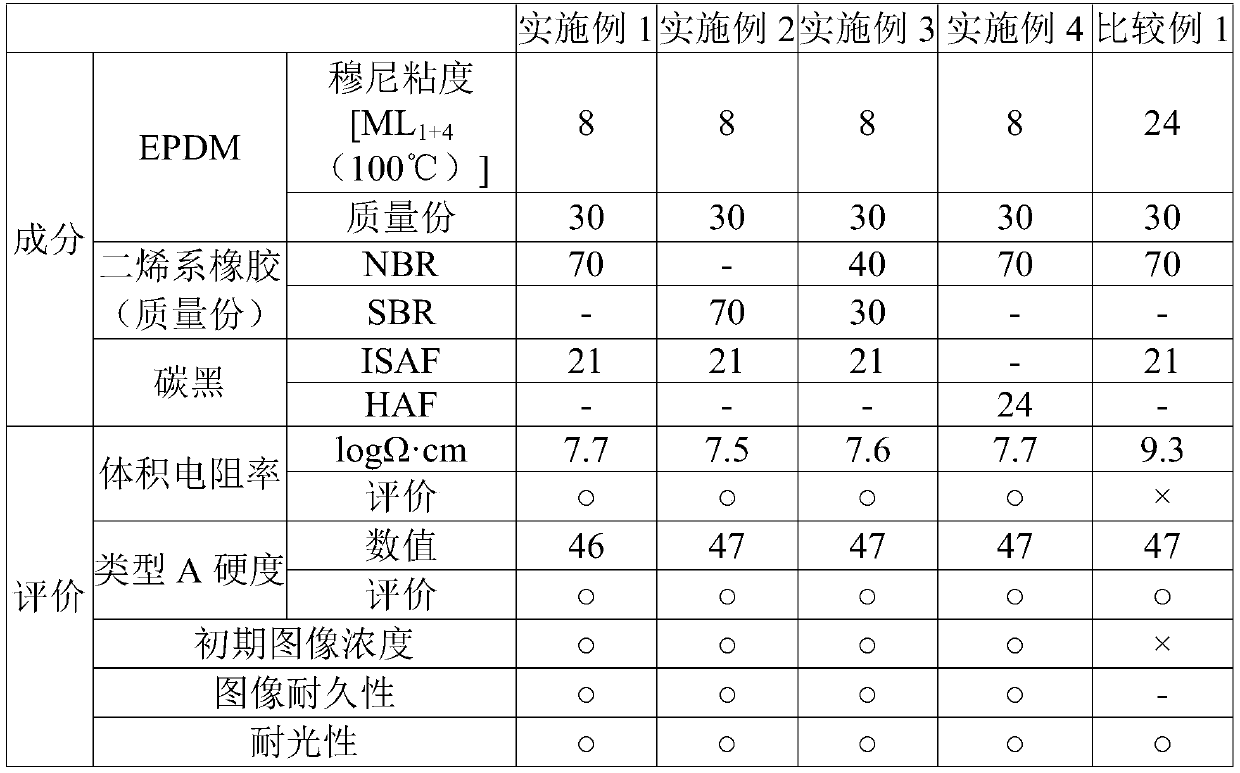

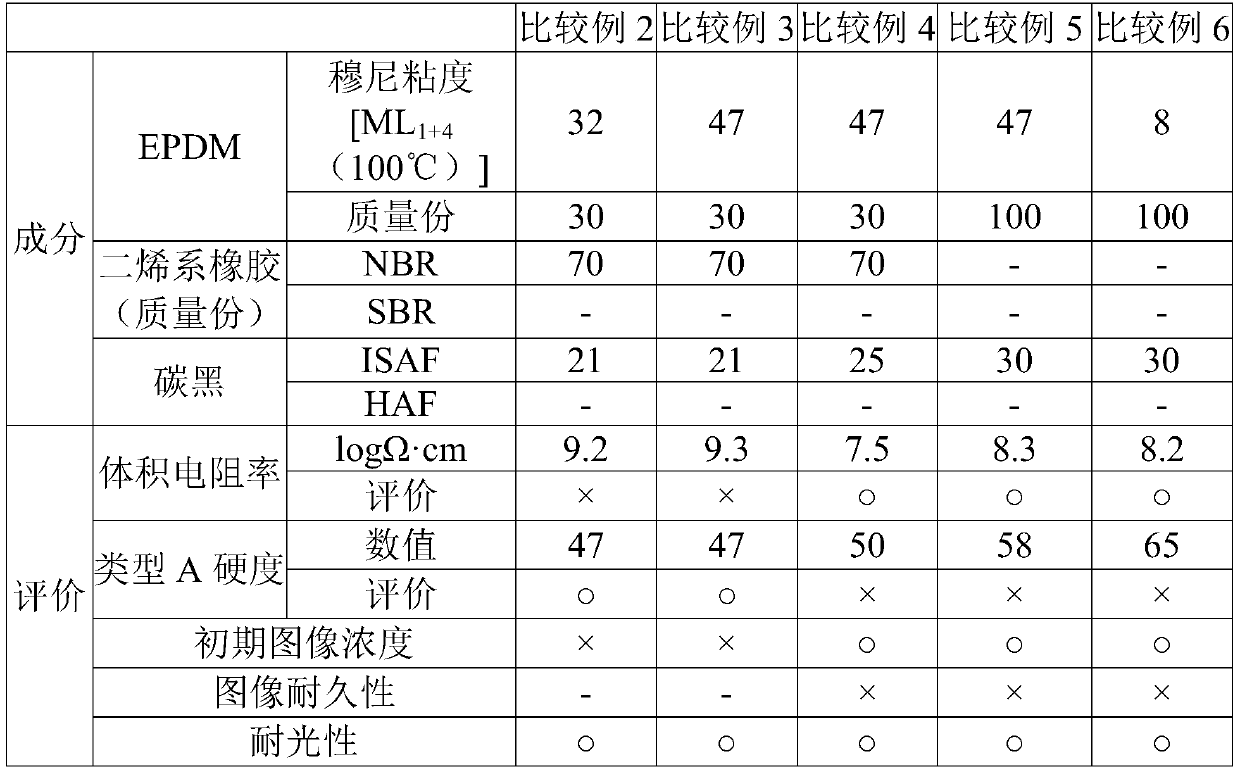

Embodiment 1

[0201] As a rubber, adjust the Mooney viscosity ML 1+4 (100°C) is EPDM below 10 [Mitsui EPT X-4010M manufactured by Mitsui Chemical Co., Ltd. mentioned above, Mooney viscosity ML 1+4 (100° C.): 8, ethylene content: 54%, diene content: 7.6%, non-oil-extended] 30 parts by mass, and NBR as a diene rubber [JSR N250SL manufactured by JSR Co., Ltd. proposed above, Low Nitrile NBR, Nitrile Content: 19.5%, Mooney Viscosity ML 1+4 (100°C): 43, non-oil-extended] 70 parts by mass.

[0202] Then, using a Banbury mixer, 100 parts by mass of the total amount of both rubbers was masticated, and firstly, each component shown in Table 1 below was added and kneaded.

[0203] [Table 1]

[0204] Table 1

[0205] Element parts by mass Crosslinking Auxiliary 2.5 carbon black 21 Processing aids 0.5

[0206] Each component in Table 1 is as follows. In addition, the parts by mass in Table 1 are parts by mass relative to 100 parts by mass of the total amount of r...

Embodiment 2

[0225] As the diene rubber, the same amount of SBR [JSR1502 manufactured by JSR Co., Ltd. proposed above, styrene content: 23.5%, Mooney viscosity ML 1+4(100° C.): 52, non-oil-extended] A rubber composition was prepared in the same manner as in Example 1, and a conductive roller was produced.

Embodiment 3

[0227] As the diene rubber, use the same NBR 40 parts by mass as in Example 1 and 30 parts by mass of SBR as in Example 2, except that a rubber composition was prepared in the same manner as in Example 1 to produce a conductive roll.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com