A processing technology of hollow building formwork

A technology for building formwork and processing technology, which is used in construction, on-site preparation of building components, building construction, etc. Grinding degree and heat resistance, etc., to achieve the effect of improving heat resistance, improving strength, and increasing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

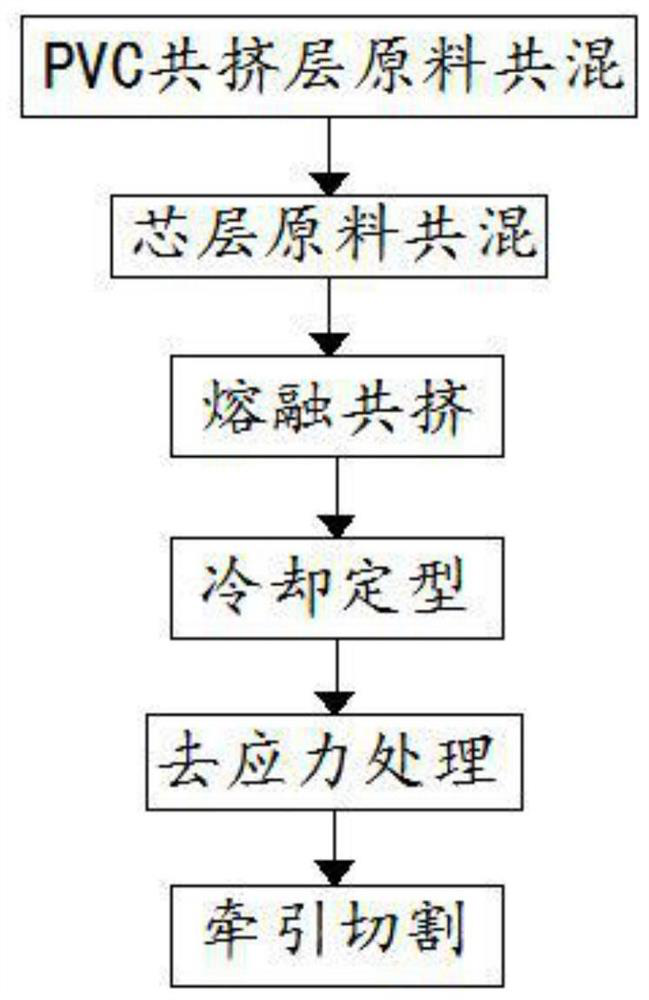

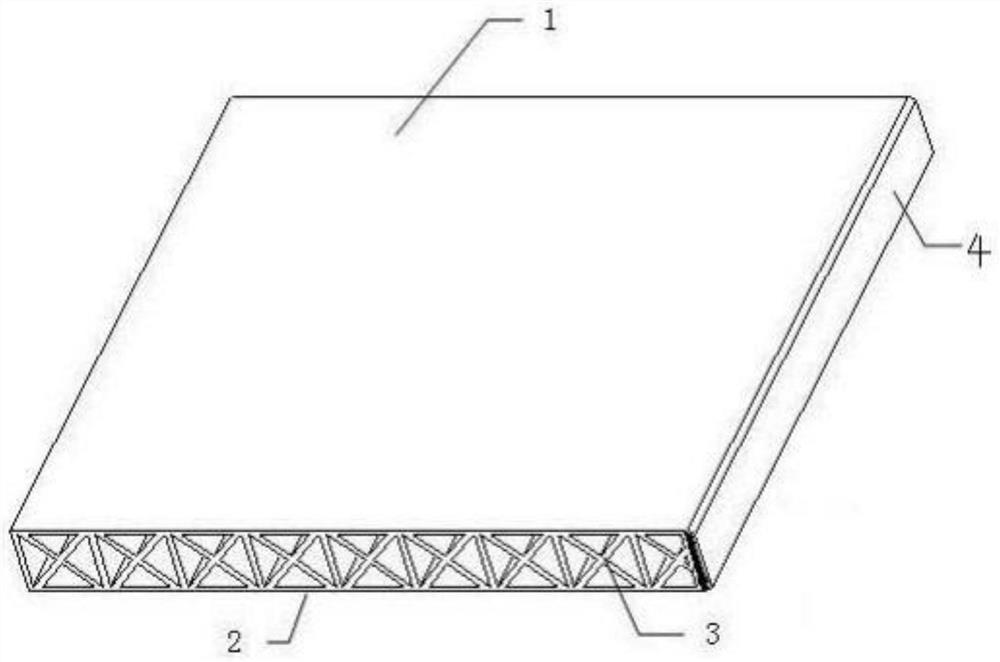

[0035] see Figure 1-2 As shown, the present embodiment provides a processing technology for hollow building formwork, comprising the following steps:

[0036] S1. Blending of raw materials for PVC co-extrusion layer: by weight, weigh 75 parts of polyvinyl chloride resin powder, 25 parts of acrylonitrile-butadiene-styrene copolymer, 8 parts of aromatic polyamide fiber, and 1.2 parts of antistatic filler. 7 parts, 7 parts of light calcium carbonate, 1.6 parts of titanium dioxide, mix and stir evenly to obtain PVC co-extrusion layer blend; wherein, the apparent density of polyvinyl chloride resin powder is 0.42-0.45g / cm 3 , the residual vinyl chloride content is less than 10ug / g; the heat distortion temperature of the acrylonitrile-butadiene-styrene copolymer is 94-96°C, the tensile strength is 52-55MPa, and the bending strength is 85-88MPa.

[0037] The preparation method of the antistatic filler is as follows: according to parts by weight, 4 parts of ultraviolet absorber 2-(2...

Embodiment 2

[0044] see Figure 1-2 As shown, the present embodiment provides a processing technology for hollow building formwork, comprising the following steps:

[0045] S1. Blending of raw materials for PVC co-extrusion layer: according to parts by weight, weigh 85 parts of polyvinyl chloride resin powder, 27 parts of acrylonitrile-butadiene-styrene copolymer, 10 parts of aromatic polyamide fiber, and 1.5 parts of antistatic filler. 8 parts, 8 parts of light calcium carbonate, 2.5 parts of titanium dioxide, mix and stir evenly to obtain PVC co-extrusion layer blend; wherein, the apparent density of polyvinyl chloride resin powder is 0.42-0.45g / cm 3 , the residual vinyl chloride content is less than 10ug / g; the heat distortion temperature of the acrylonitrile-butadiene-styrene copolymer is 94-96°C, the tensile strength is 52-55MPa, and the bending strength is 85-88MPa.

[0046] The preparation method of the antistatic filler is as follows: according to parts by weight, use 30 parts of ...

Embodiment 3

[0053] see Figure 1-2 As shown, the present embodiment provides a processing technology for hollow building formwork, comprising the following steps:

[0054] S1. Blending of raw materials for PVC co-extrusion layer: according to parts by weight, weigh 85 parts of polyvinyl chloride resin powder, 27 parts of acrylonitrile-butadiene-styrene copolymer, 11 parts of aromatic polyamide fiber, and 1.8 parts of antistatic filler 9 parts of light calcium carbonate, 3 parts of titanium dioxide, mix and stir evenly to obtain PVC co-extrusion layer blend; the apparent density of polyvinyl chloride resin powder is 0.42-0.45g / cm 3 , the residual vinyl chloride content is less than 10ug / g; the heat distortion temperature of the acrylonitrile-butadiene-styrene copolymer is 94-96°C, the tensile strength is 52-55MPa, and the bending strength is 85-88MPa.

[0055]The preparation method of the antistatic filler is as follows: according to parts by weight, 4.5 parts of ultraviolet absorber 2-hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com