A kind of "thermo-electric" coupling unclad preparation method of tial alloy plate

A technology of alloy sheet and sheath, which is applied in the field of "thermo-electric" coupled no-sheath preparation of TiAl alloy sheet, can solve the problems of poor uniformity and mechanical properties of the sheet, poor deformation coordination, and low material utilization rate, etc., to avoid Effects of absorbing rolling deformation, reducing deformation resistance, and improving composition and grain size unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of Ti-44Al-8Nb-(B, Y) alloy plate "thermo-electric" coupling without jacket is as follows:

[0040] Step 1, weighing raw materials:

[0041]According to the atomic percentage of each component, the alloy composition is 44% Al, 8% Nb, 0.1% X (X is a 1:1 combination of B and Y elements), and the balance is Ti and unavoidable impurity elements. Weigh high-purity titanium sponge, high-purity aluminum, aluminum-niobium alloy (with a Nb content of 54.56%), aluminum-yttrium alloy (with a Y content of 87.3%), and a total of 10Kg of boron powder as raw materials.

[0042] Step 2. Ingot melting and casting:

[0043] The high-purity sponge titanium, high-purity aluminum, aluminum-niobium alloy, aluminum-yttrium alloy, and boron powder weighed in step 1 are added to a water-cooled copper crucible for melting in a vacuum induction shell melting furnace. The melting atmosphere is an argon atmosphere, and the argon pressure is 0.95~1MPa, the mass purity of arg...

Embodiment 1

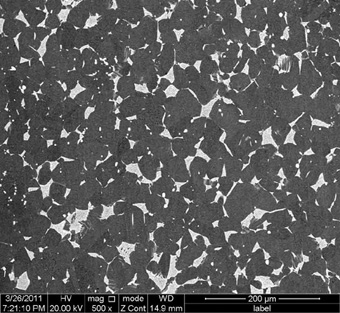

[0058] The TiAl alloy sheet material surface quality that embodiment 1 step 5 obtains is good, without obvious crack, as figure 1 shown.

Embodiment 2

[0060] The preparation method of Ti-43Al-4Nb-2Mo-2V-0.5Ni alloy plate "thermo-electric" coupling without jacket is as follows:

[0061] Step 1, weighing raw materials:

[0062] According to the atomic percentage of each component, the alloy composition is 43% Al, 4% Nb, 2% V, 2% Mo, 0.5% Ni, and the balance is Ti and unavoidable impurity elements. Weigh high-purity titanium sponge, high-purity aluminum, aluminum-niobium alloy (Nb content is 54.56%), aluminum-molybdenum alloy (Mo content is 55.35%), aluminum-vanadium alloy (V content is 52.12%), and high-purity nickel powder in total 15Kg as raw material.

[0063] Step 2. Ingot melting and casting:

[0064] Add the high-purity sponge titanium, high-purity aluminum, aluminum-niobium alloy, aluminum-molybdenum alloy, aluminum-vanadium alloy, and high-purity nickel powder weighed in step 1 into a water-cooled copper crucible for melting in a vacuum induction shell melting furnace, and pour the melt to 500 In the metal casting m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com