Bobbin loader used for industrial sewing machine

A technology for industrial sewing machines and thread reels, which is applied in the field of sewing machine manufacturing, can solve the problems of large wire space occupation, low wire efficiency, loose yarn edges, etc., and achieve the effects of reducing occupied area, improving efficiency, and promoting fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

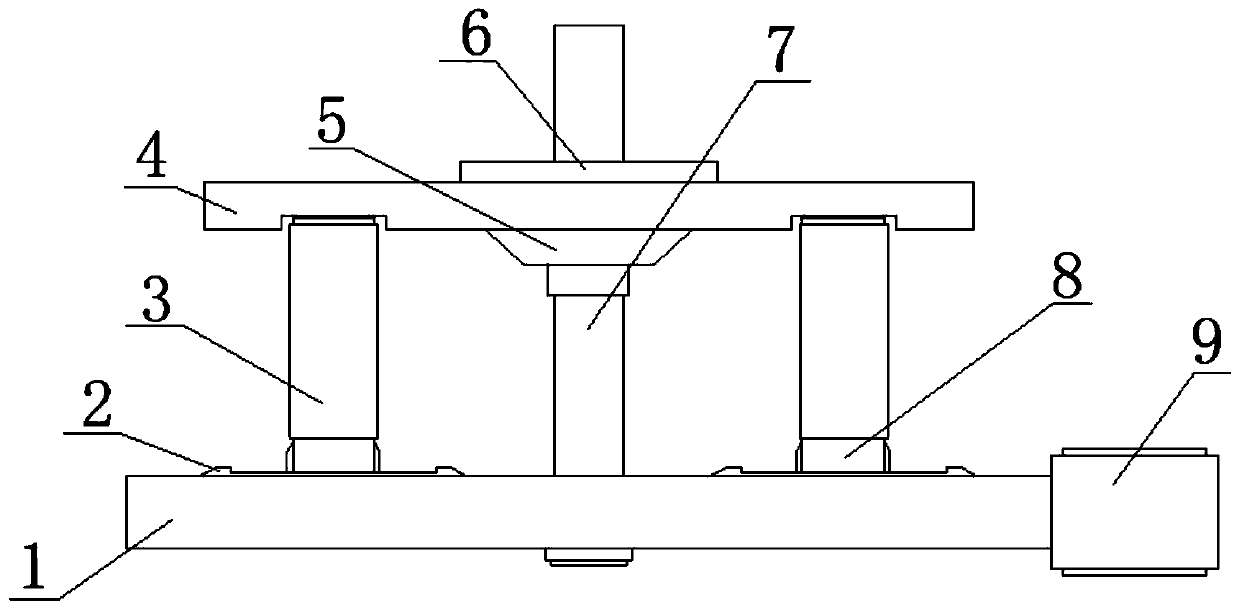

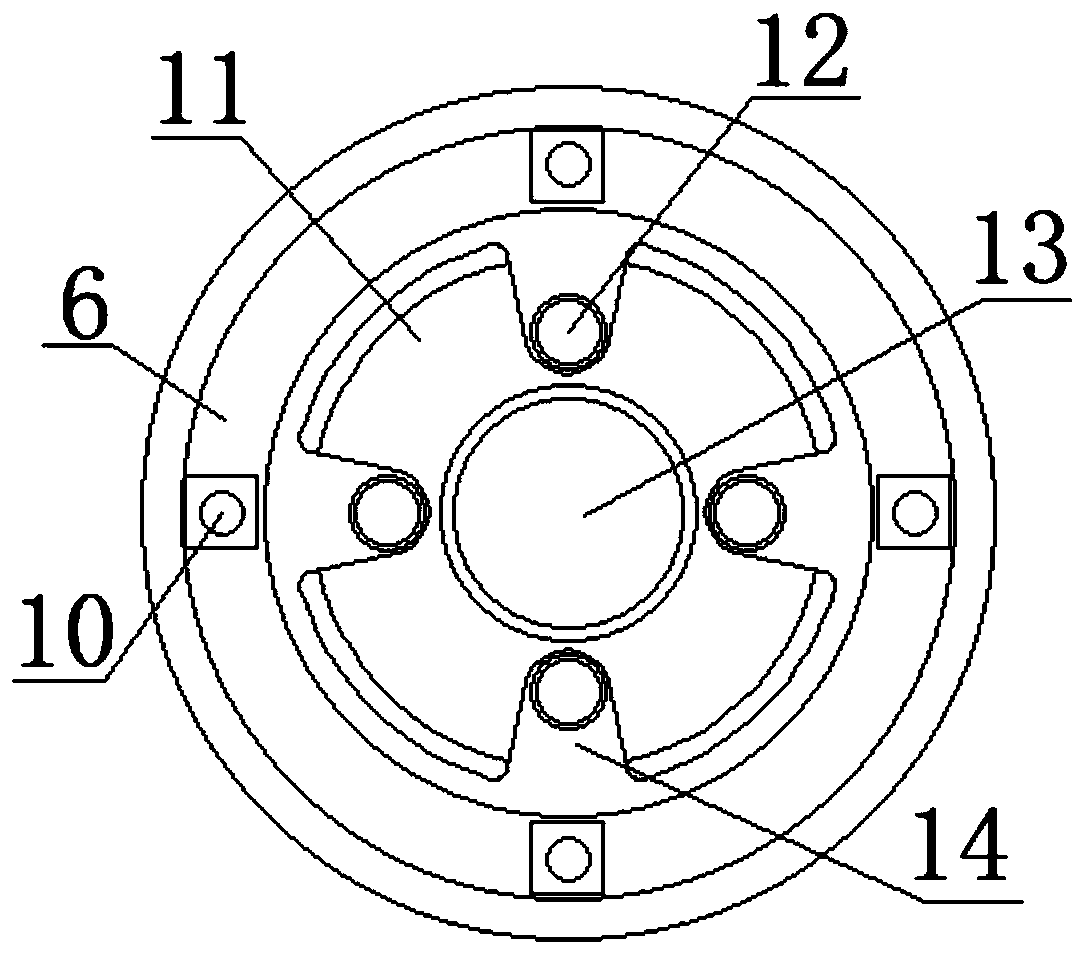

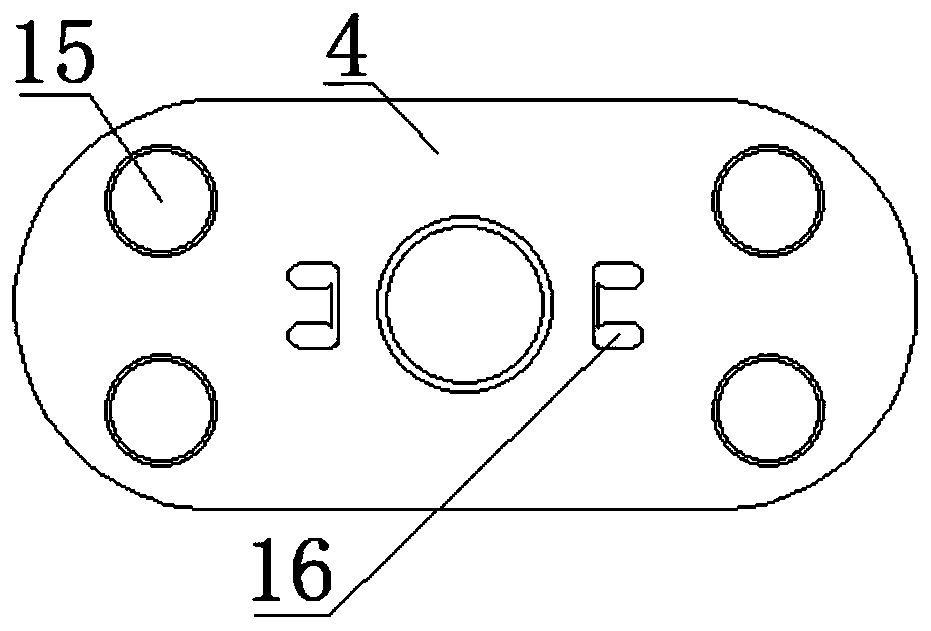

[0030] Such as figure 1 As shown, the thread reel rack for industrial sewing machines in this embodiment includes a bottom plate 1 and a two-dimensional linear module 2 . Bottom plate 1 adopts steel plate to make, and steel plate can be made into groove shape, is used for collecting the debris such as thread end that produces when the wire reel frame works normally. In order to facilitate the movement of the wire rack, a two-dimensional linear module needs to be introduced. The fixed module of the two-dimensional linear module is fixed on the ground, the moving module of the two-dimensional linear module slides vertically relative to the fixed module of the two-dimensional linear module, and the bottom of the base plate 1 is welded on the bottom of the two-dimensional l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com