A large-resistance casing railway sleeper for automatic monitoring of train status

A technology for train status and automatic monitoring, applied in railway transportation, railway transportation, roads, etc., can solve the problems that manual inspection cannot meet real-time monitoring, the effect of manual inspection is unstable, and the inspection effect and quality are reduced. The work intensity and the possibility of missed detection, the effect of eliminating hidden dangers or failures in operation, and improving reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

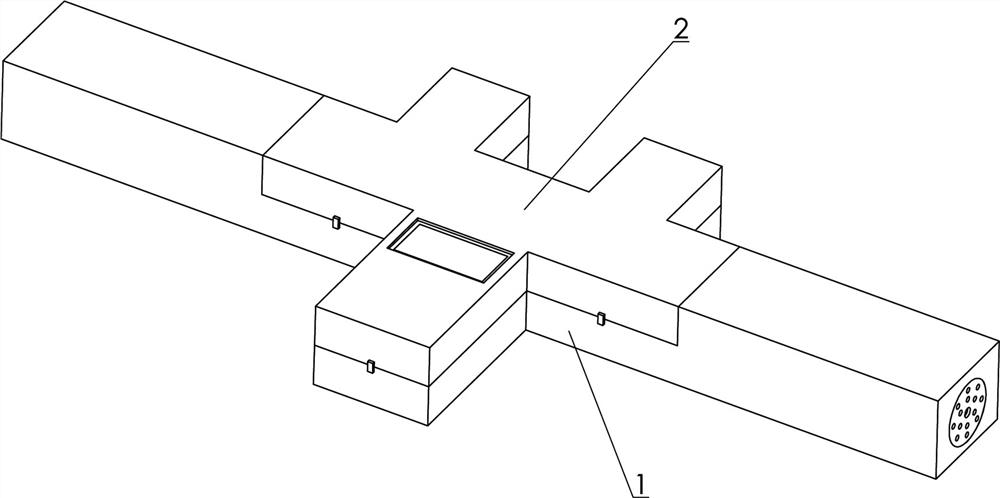

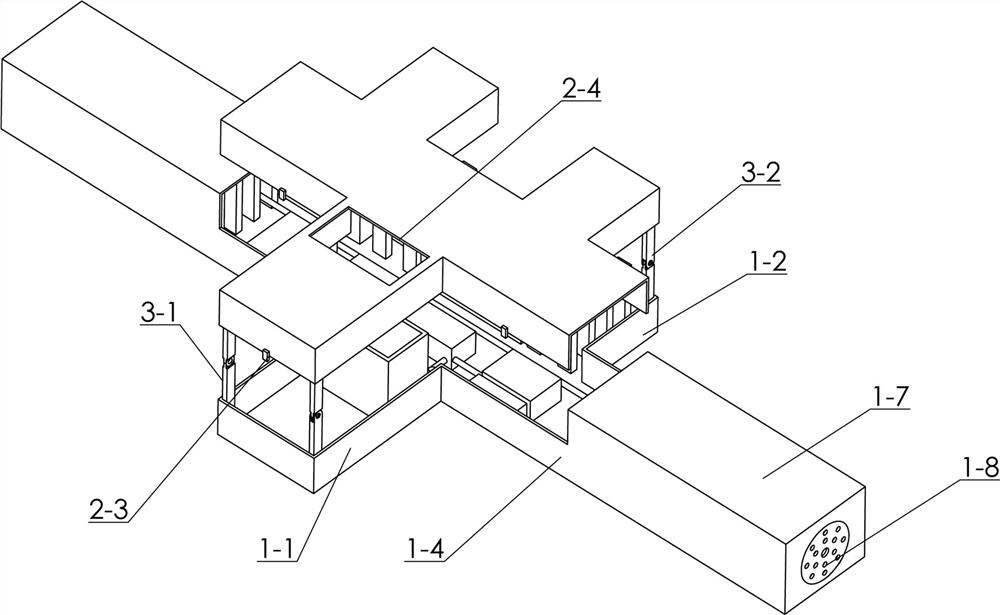

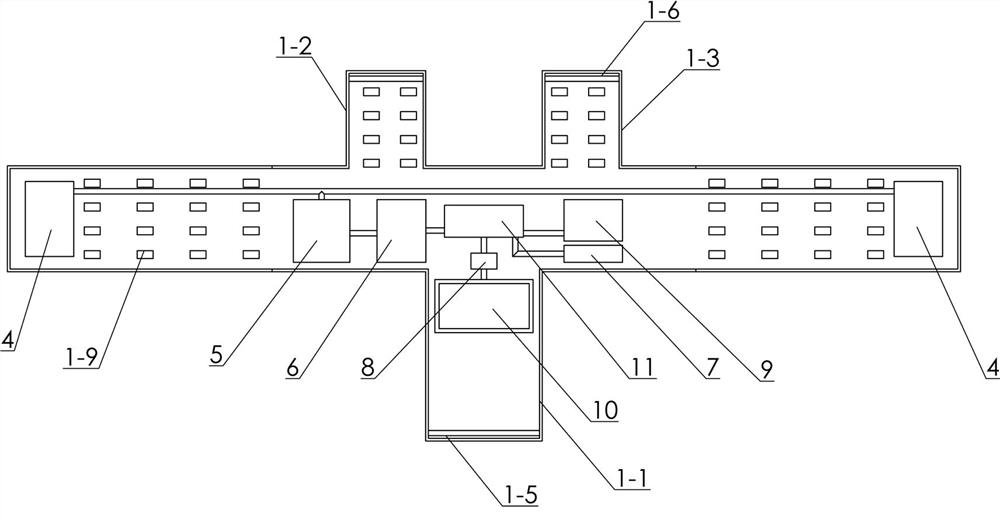

[0036] as attached Figure 1-4 As shown, the present invention includes a fixed sleeper 1, a moving sleeper 2 and a connecting assembly,

[0037] The fixed sleeper 1 includes a long rib 1-4, which is characterized in that the front end of the long rib 1-4 is provided with a first convex limit block 1-1, and the rear end is provided with a second convex limit block 1 -2 and the third convex limit block 1-3, the first convex limit block formed between the second convex limit block 1-2 and the third convex limit block 1-3 Block 1-1 is adapted to the connection groove, the first convex limit block 1-1 is provided with the first front connecting shaft 1-5, the second convex limit block 1-2 and the first The rear second connecting shaft 1-6 is arranged in the three-convex limit block 1-3,

[0038] Fixed protective covers 1-7 are arranged symmetrically at both ends of the long ribs 1-4,

[0039] The moving sleeper 2 is embedded in the groove between the fixed protective covers 1-7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com