Vibration-attenuating drive connection device of electromagnetic power-off brake

A technology for electromagnetic loss of power and connection device, applied in the field of machinery, can solve problems affecting user user experience, noise and vibration, etc., and achieve the effect of improving user experience, eliminating noise, and good positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

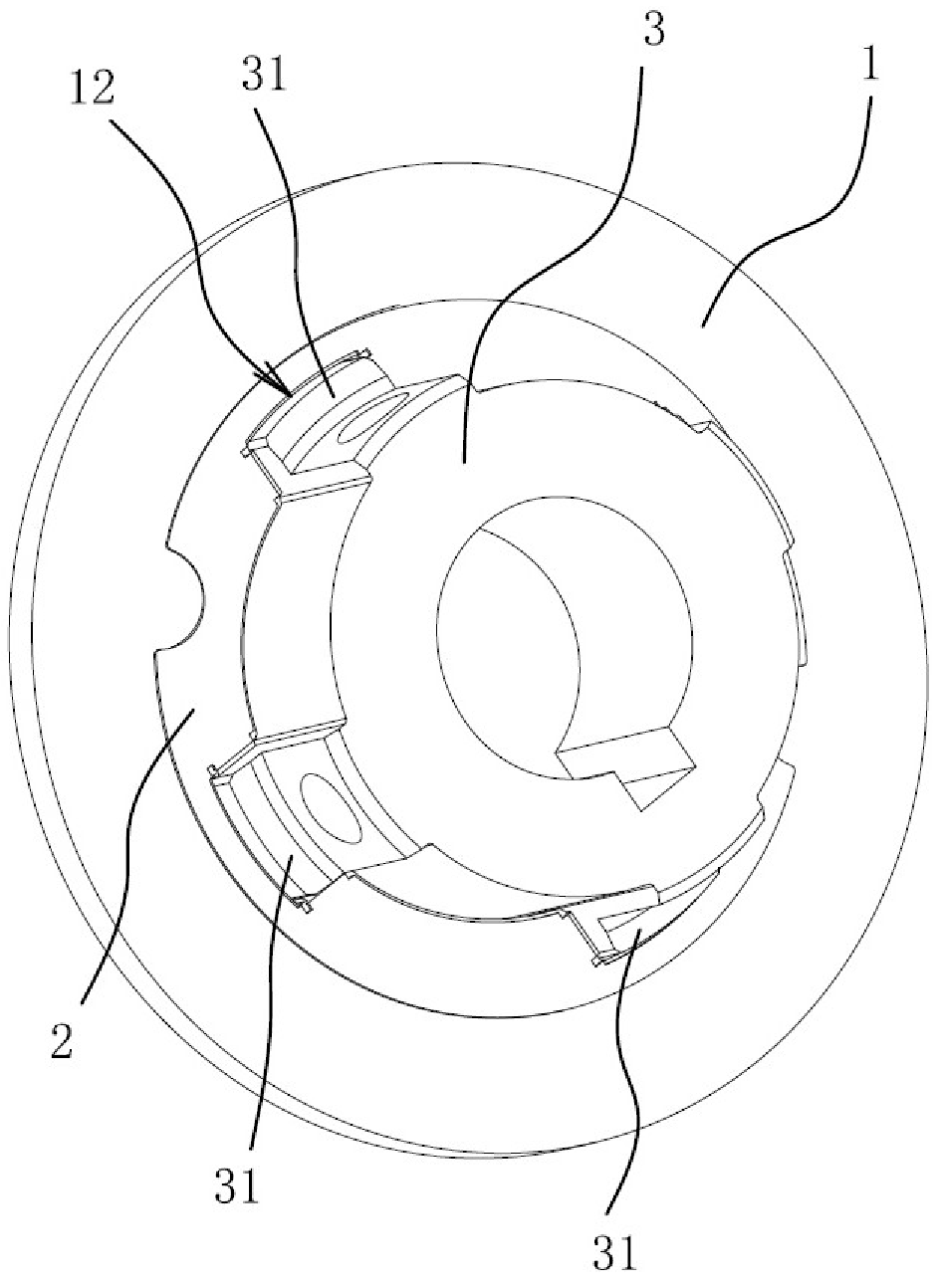

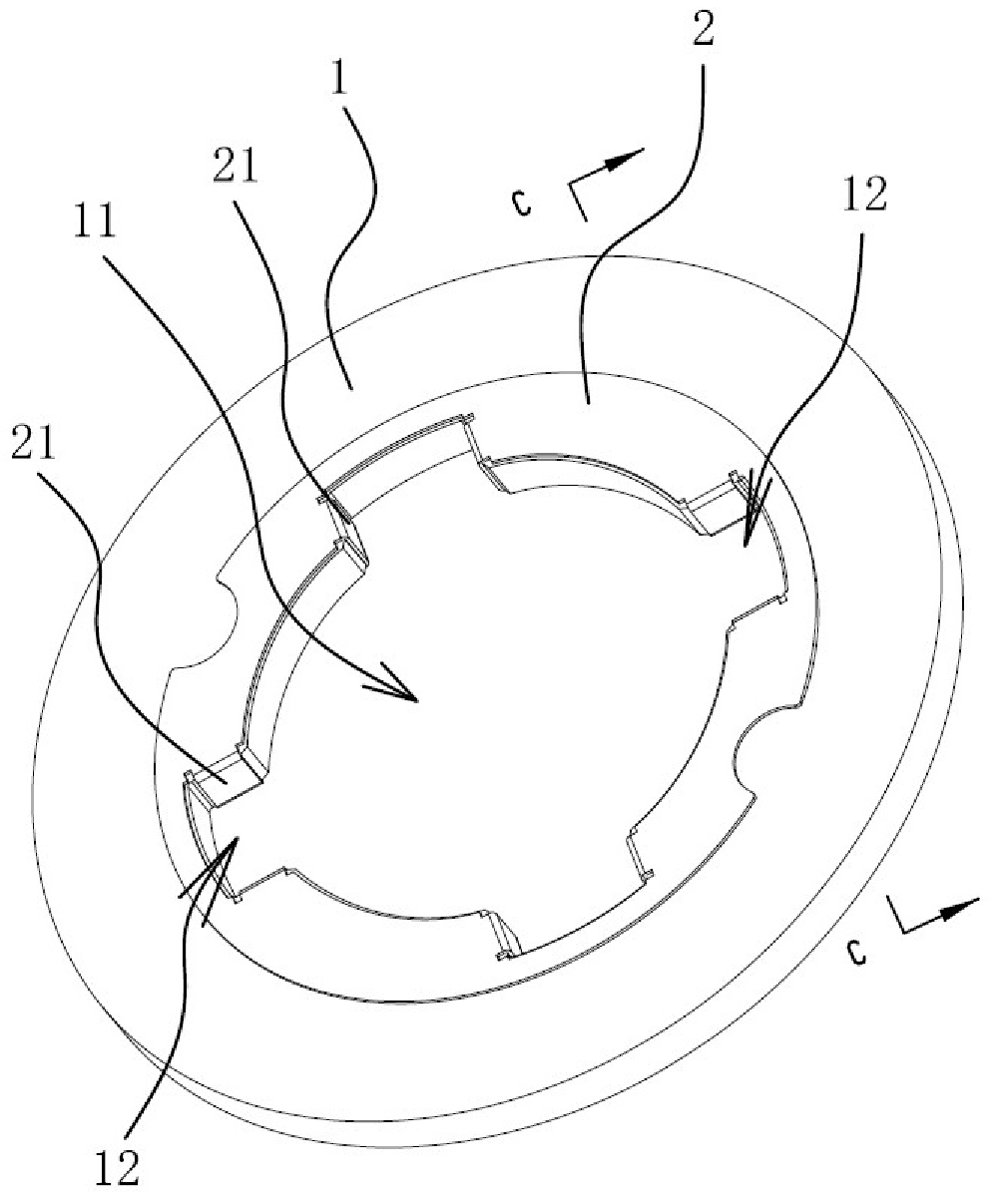

[0032] Such as figure 1 with figure 2 As shown, the vibration-damping transmission coupling device of the electromagnetic power-off brake includes a brake disc 1, the middle part of the brake disc 1 is provided with a connection hole 11, and the hole wall of the connection hole 11 is recessed to form an inner spline groove 12.

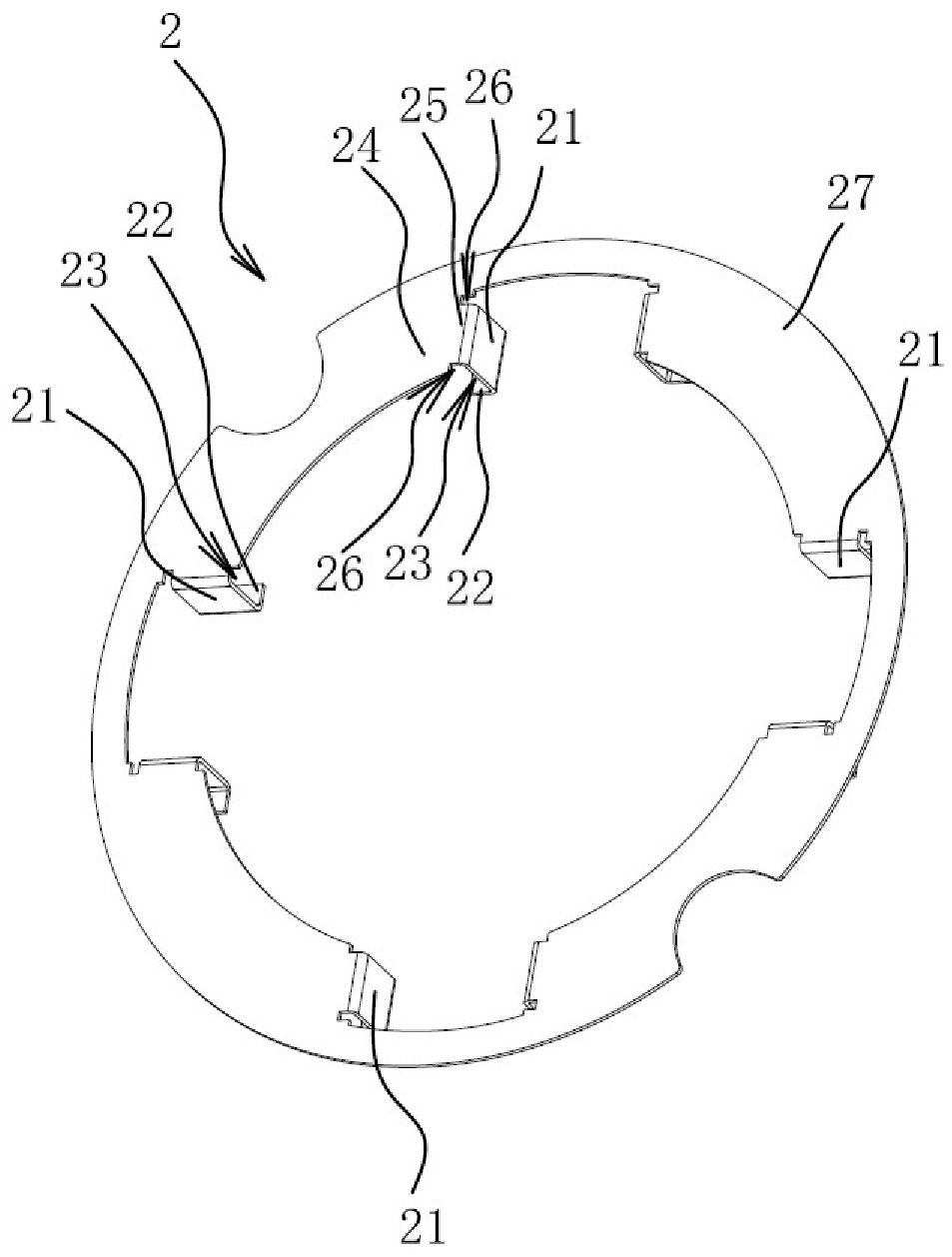

[0033] An elastic sheet 2 is arranged on the brake disc 1, and the elastic sheet 2 is made of metal elastic material. The elastic sheet 2 includes an annular elastic sheet substrate 27 that is in contact with the end surface of the brake disc 1, and the elastic sheet substrate 27 is provided with each spline groove 12 corresponding to the center hole of the brake disk to be folded inwards and formed into the spline groove. The baffle 21 next to the two side walls of the spline groove, such as Figure 4 with Figure 5 As shown, when the blocking piece is in a free state, an angle B is formed between the side wall of the spline groove and the angle B...

Embodiment 2

[0037] Embodiment 2: as Figure 6-Figure 10 As shown, when the blocking piece 21 is in a free state, it has a curved surface shape, and the curved surface shape has an arc-shaped cross section, so that an elastic gap 1211 is formed between the blocking piece 21 and the side wall 121 of the spline groove 12 when the blocking piece 21 is in a free state. The curved shape of the baffle can be compressed by the splines of the rotor so as to eliminate the fit gap between the splines of the rotor and the spline grooves of the brake disc. Such as Figure 10As shown, the minimum distance L between two adjacent baffles 21 is smaller than the width of the rotor spline, so that before the spline of the rotor fits with the brake disc, the spline groove of the brake disc is defined by the two baffles The width is less than the width of the rotor splines. All the other structures of this embodiment are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com