A soft-landing pwm control method and system for piezoelectric high-speed switching valves

A high-speed switching valve and control method technology, applied in the direction of valve operation/release device, valve fluid energy absorption device, valve details, etc., can solve the problem of strong system vibration, high noise, and material wear on the surface of the valve core and valve seat and other issues to achieve the effect of maintaining dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

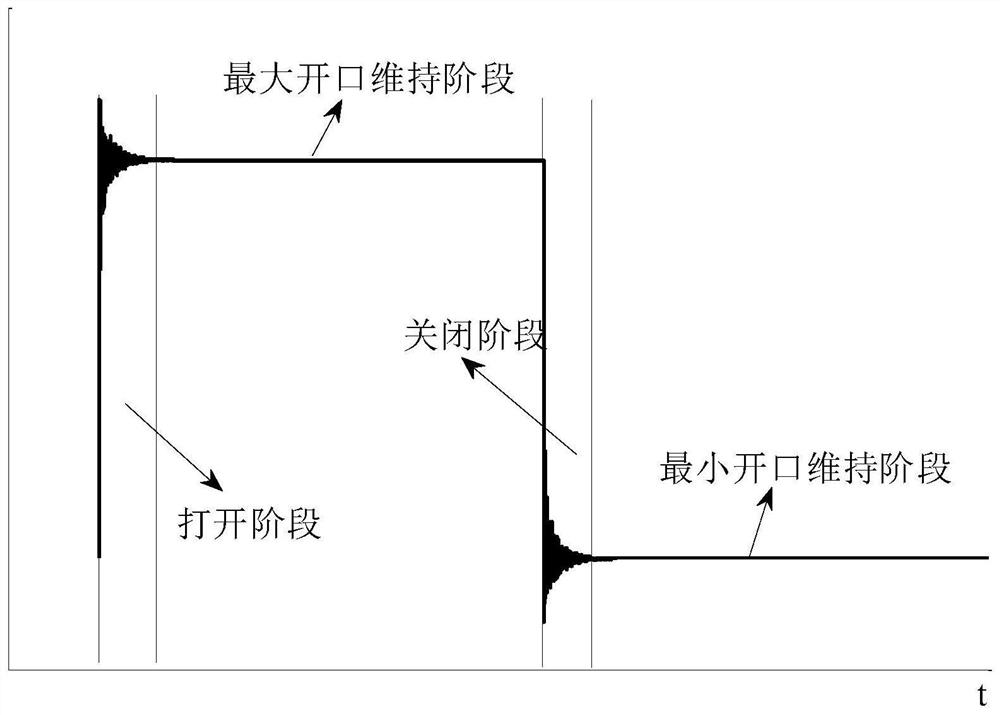

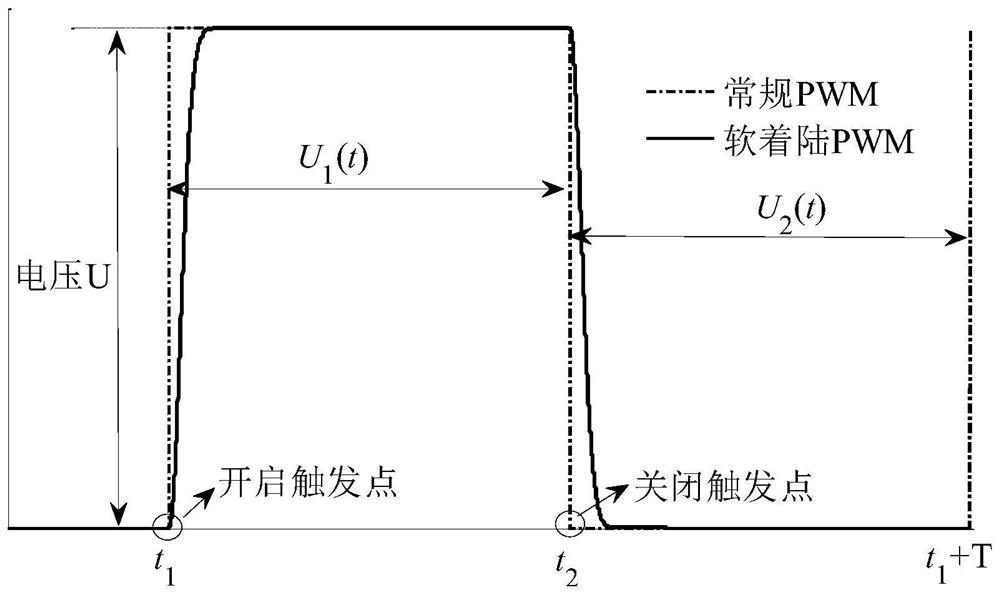

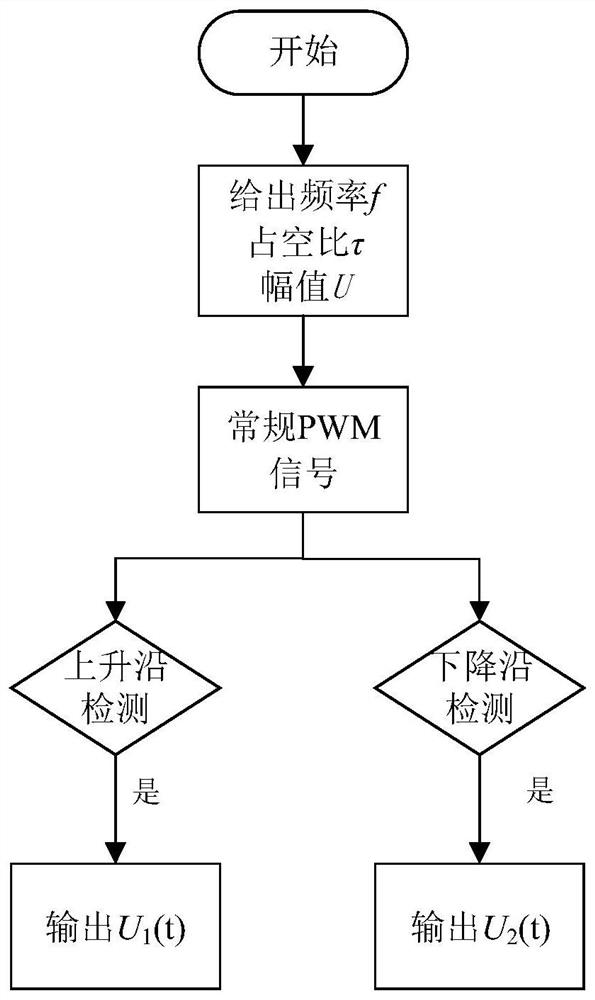

[0033] Such as figure 1 As shown, the embodiment of the present invention provides such as figure 1 As shown, the present invention discloses a soft-landing PWM control method for piezoelectric high-speed switching valves, including defining the working process of the piezoelectric high-speed switching valve spool into four stages in one cycle, and the four stages are respectively: The spool opening stage, the spool maximum opening maintenance stage, the spool closing stage and the spool minimum opening maintenance stage. The spool opening stage is when the spool moves from the minimum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com