A flow automatic control valve

A technology for automatic valve and flow control, applied in valve details, valve devices, engine components, etc., can solve the problems of low regulation precision, inability to control water flow, and high difficulty in operation, and achieve high regulation precision, prolong life, and difficulty in operation. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

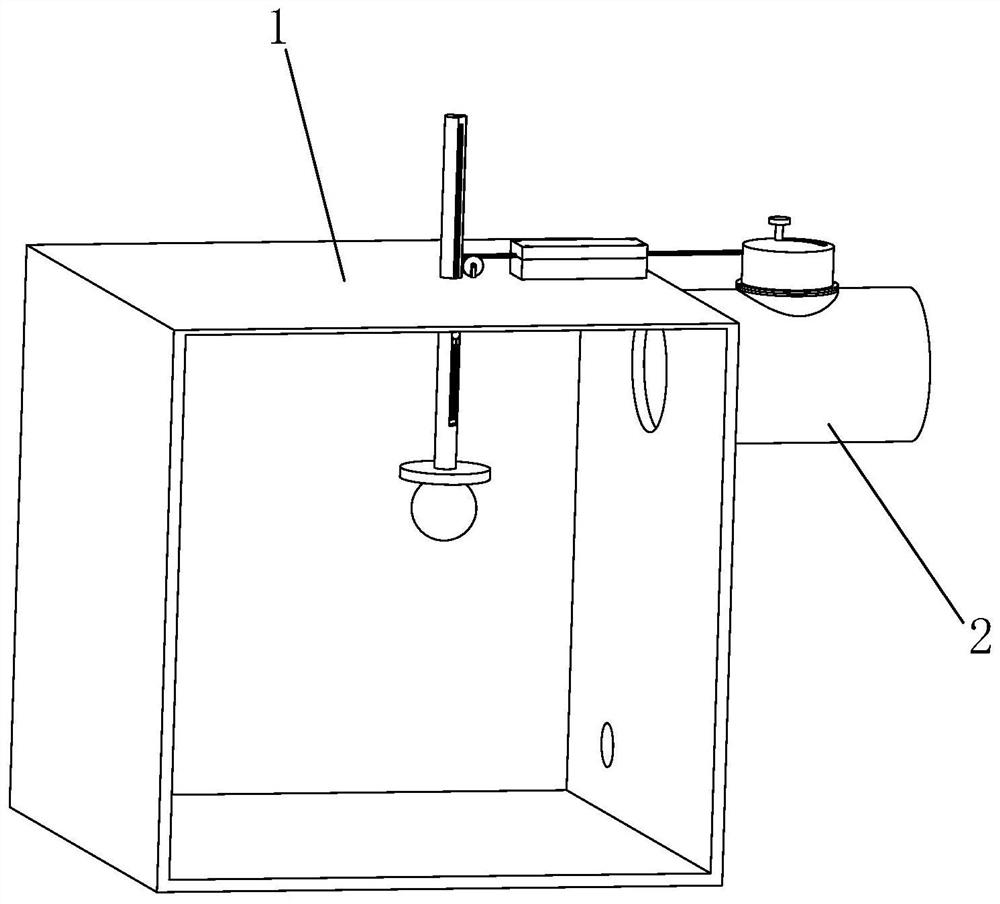

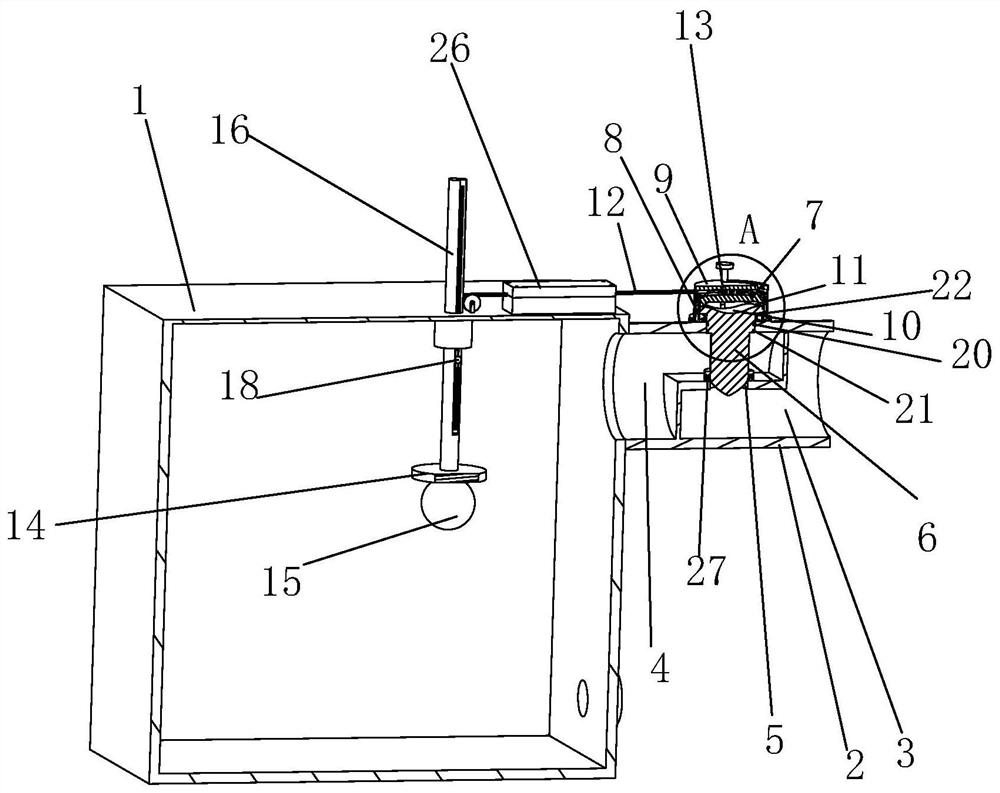

[0025] Such as figure 1 As shown, an automatic flow control valve is fixedly connected with a water tank 1. The water tank 1 is provided with a water outlet and a water inlet, and the valve body 2 is connected to the water inlet.

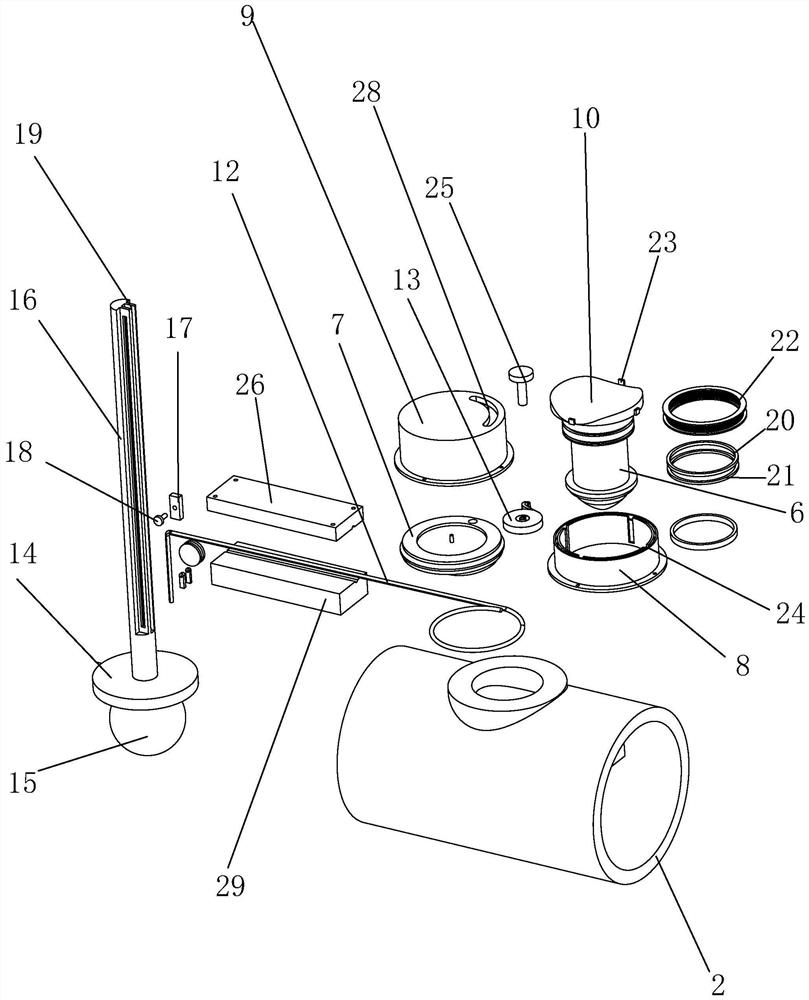

[0026] Such as figure 2 As shown, the valve body 2 is provided with a first space 3 and a second space 4, the first space 3 and the second space 4 communicate through the first through hole 5, water passes through the first through hole 5 from the first space 3, and then flows from the first space 3 to the second space 4. The first pass enters the second space 4, and finally flows into the water tank 1 from the second space 4.

[0027] Such as Figure 4 As shown, the contact surface between the valve core 6 and the valve body 2 is provided with a first ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap