Small alcohol-based fuel self-heating, evaporating and combusting device for micro-flow control

An alcohol-based fuel and combustion device technology, which is applied to heating fuels, heating methods, liquid heating fuels, etc., can solve the problems that the burner cannot be extinguished, the minimum fire is extinguished, and the liquid alcohol-based fuel cannot be ignited, so as to improve the ignition success. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

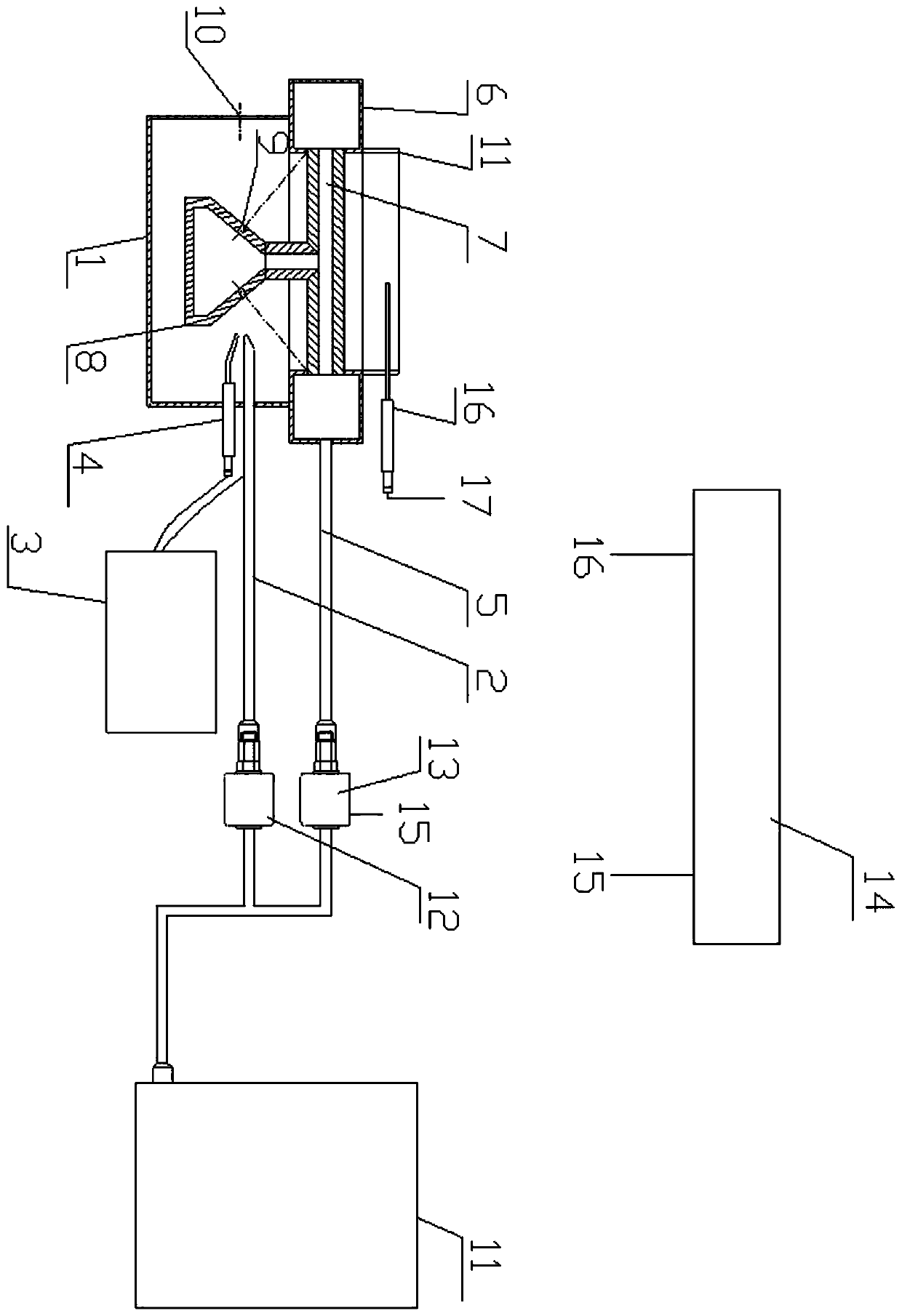

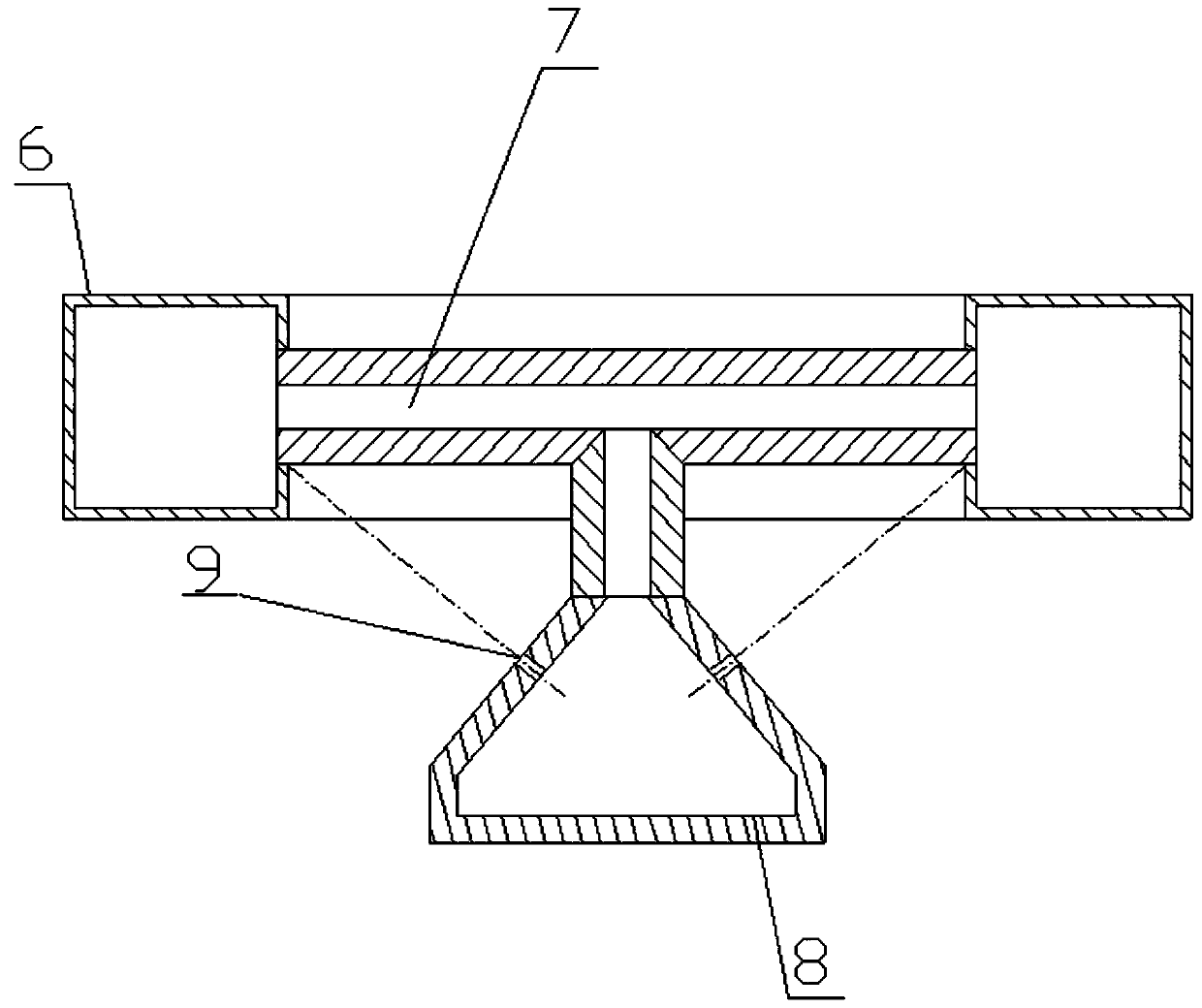

[0031] Such as figure 1 As shown, a small alcohol-based fuel self-heating vaporization combustion device that realizes micro-flow control includes an oil supply system, an ignition system and a burner 1 . The fuel supply system is connected to the burner 1 through an ignition oil pipe 2 and inputs liquid alcohol-based fuel into the burner 1, and the ignition system is connected to the interior of the burner 1 and input to the ignition oil pipe 2. Liquid alcohol-based fuel is pulsed to achieve ignition. The ignition system includes a pulse generator 3 and an ignition needle 4 . The pulse generator 3 is located outside the burner 1 . The ignition pin 4 is at a corresponding position in the burner 1 . One end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com