Igniting method of oil burner

A burner and fuel oil technology, applied in the direction of combustion ignition, combustion method, incandescent ignition, etc., can solve the problems of automatic ignition and detection of fuel burners, low mechanical strength, short service life, etc., and achieve automatic adjustment control The effect of ignition duration, automatic adjustment of preheating time, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

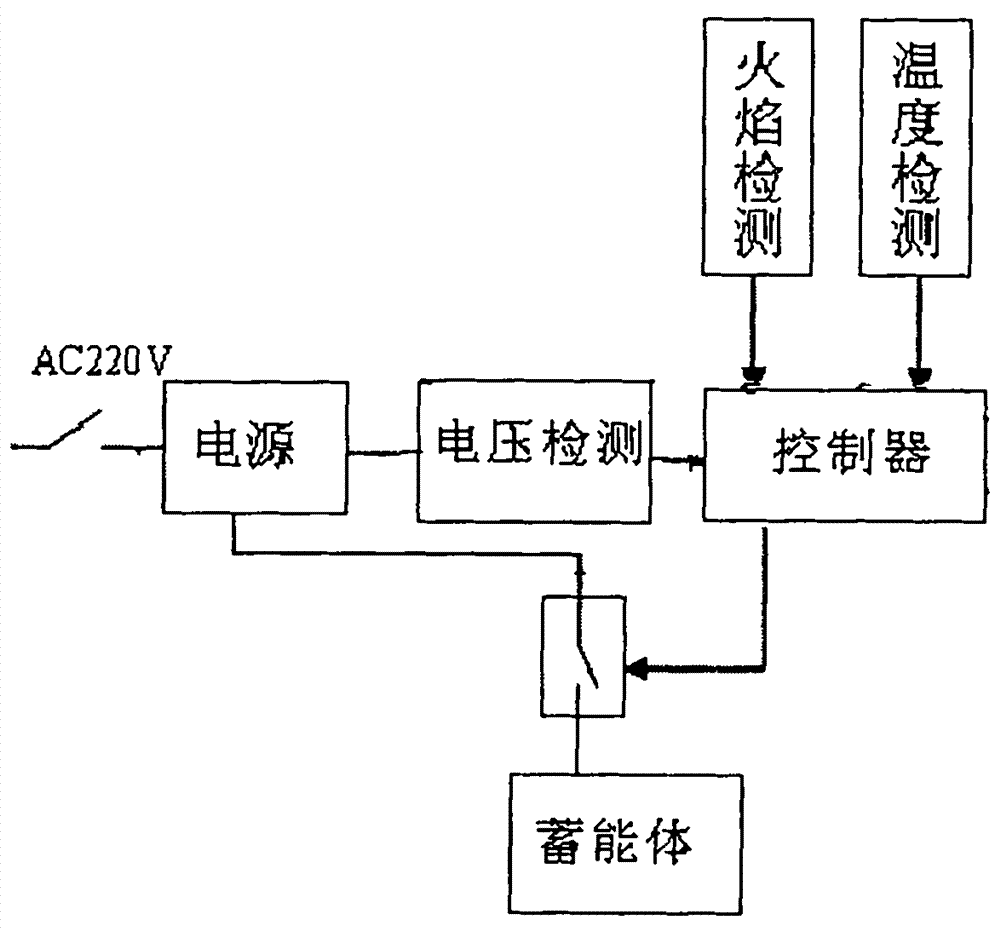

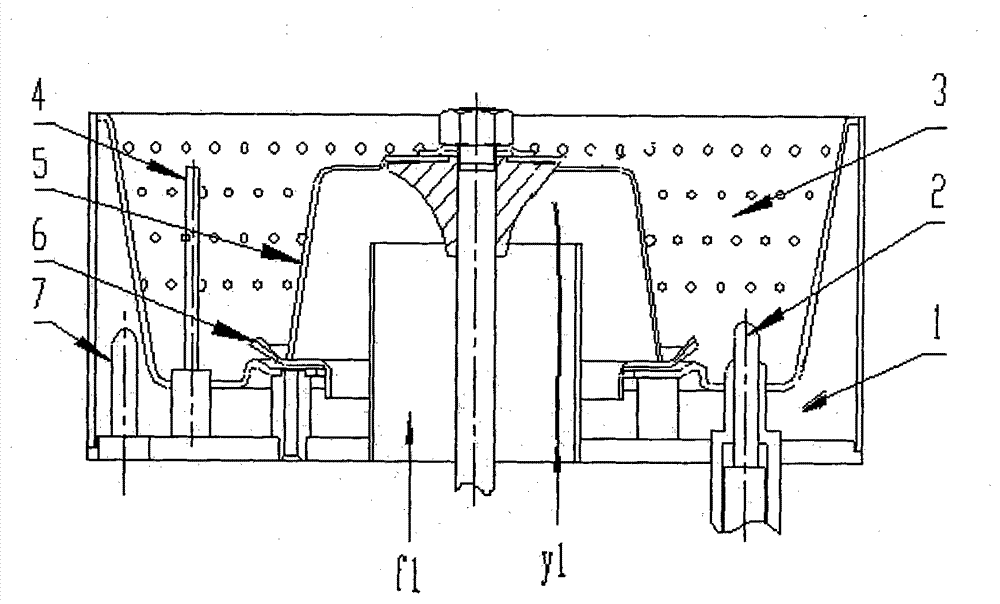

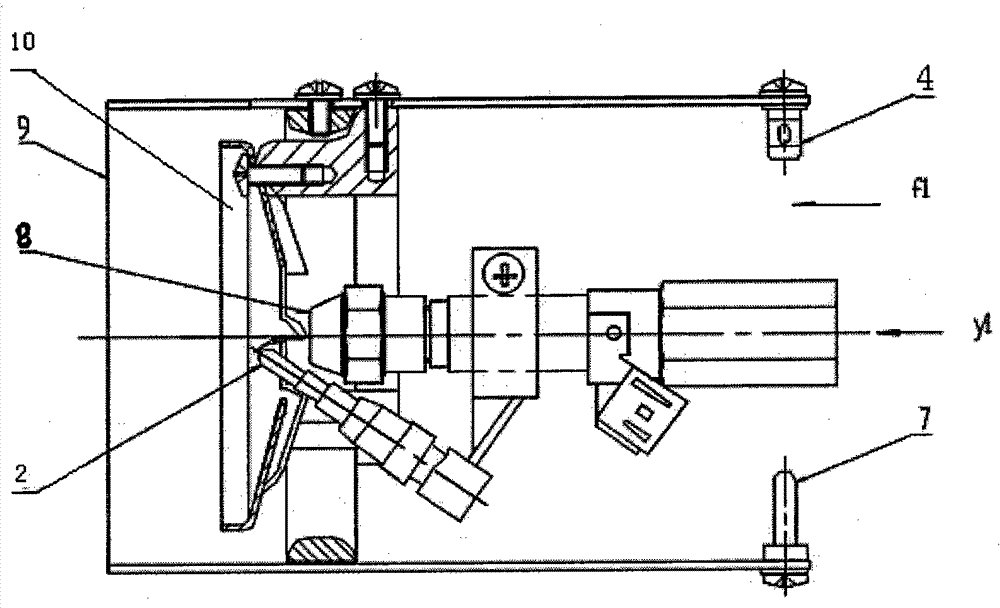

[0018] figure 2 It is the first embodiment of the present invention, which is applied to the premixed burner. The energy storage body 2 is installed in the thermal stability chamber 3 and is about 5-10mm away from the edge of the fin 6 on the evaporator 5. The high temperature area of the energy storage body 2 It is roughly on the same level as the fins 6; the temperature sensor 7 is installed in the pre-mixing chamber 1 to detect the ambient temperature of the ignition. see figure 1 , the voltage detection will transmit the power supply voltage value and the temperature sensor to the ignition environment temperature value to the controller, and the computer in the controller will use the mathematical model or interpolation method to calculate and set the best warm-up time for the energy storage body 2, when the energy storage body 2 When the temperature reaches above 1000°C, the controller enters the ignition program, the air enters the thermal stability chamber 3 along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com