Humidification film for air conditioning equipment, and air conditioning equipment

A technology of air-conditioning equipment and humidification film, which is applied in the field of air-conditioning equipment and humidification film, which can solve the problems of difficulty in increasing the humidification capacity, slow evaporation rate, and low humidification capacity of the humidification film, and achieve good moisture-conducting and quick-drying performance. Simple, good humidification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

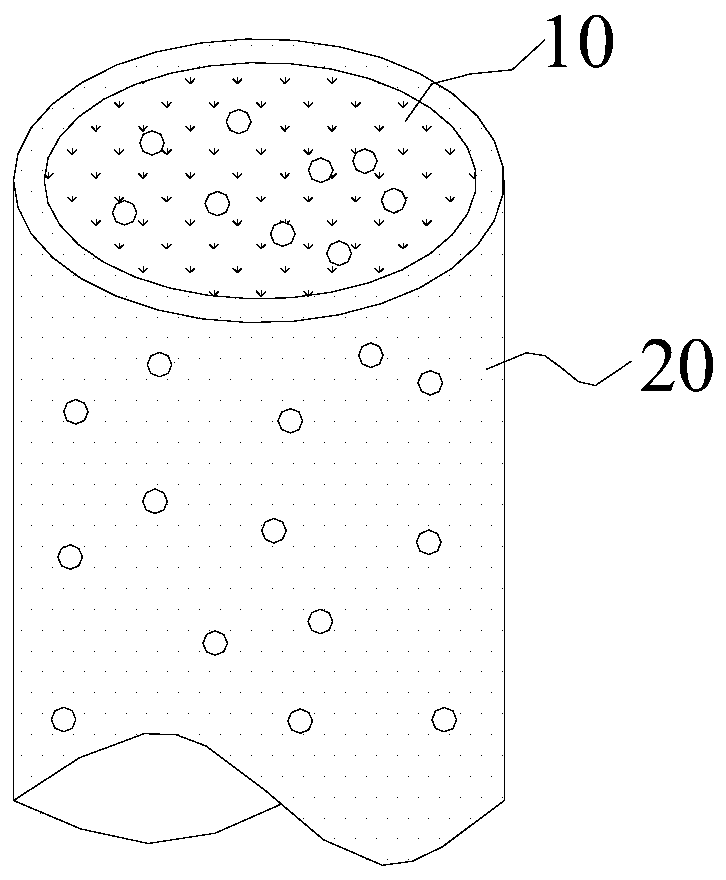

[0065] The humidifying membrane is a non-woven fabric composed of composite fibers and viscose fibers, wherein the core layer of the composite fiber is polyacrylonitrile fiber, the diameter of the core layer is 0.5 μm, the pore density in the core layer is 500ppi, and the pore diameter is 100nm. It is nylon, the thickness of the cortex is 1 μm, the pore density in the cortex is 500ppi, and the pore diameter is 100nm. Based on the total mass of fibers constituting the humidification membrane, the content of composite fibers is 30%, and the content of viscose fibers is 70%.

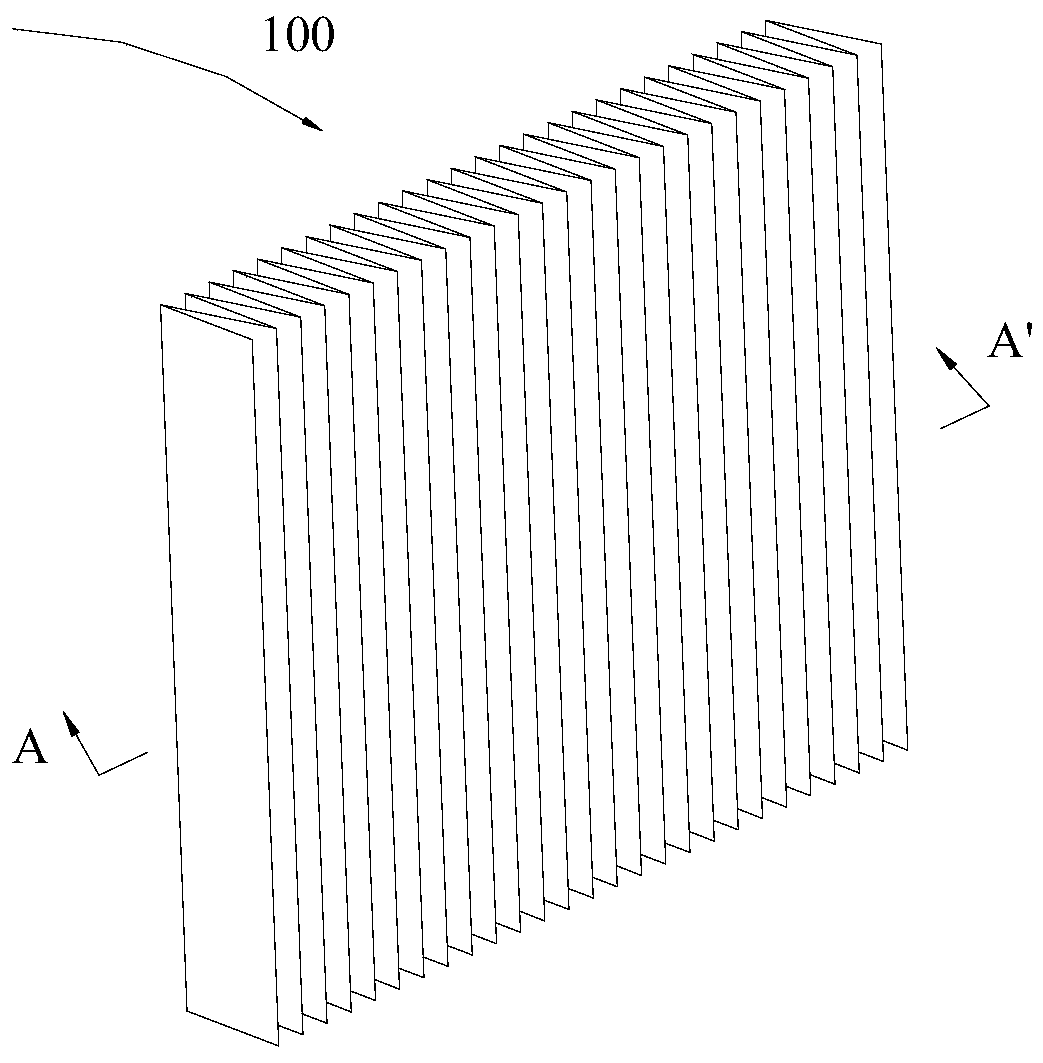

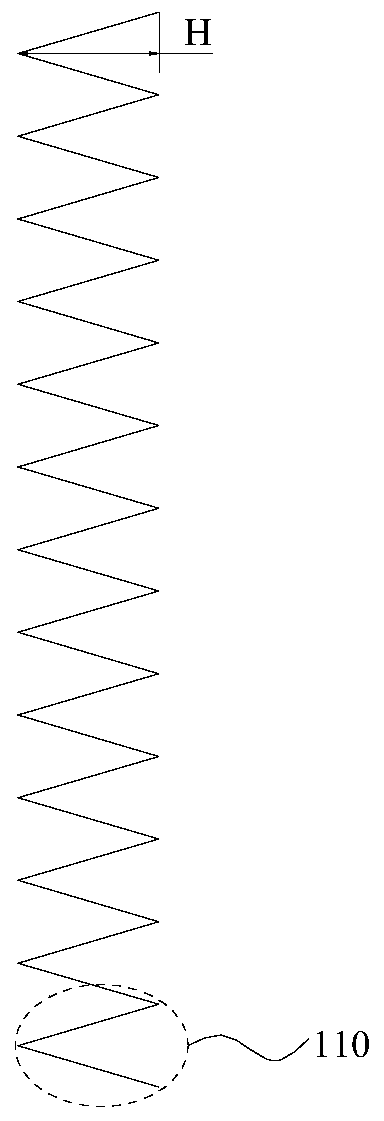

[0066] Make the humidification membrane into a sawtooth shape, the tooth height is 20mm, and the tooth density is 300 / m, and the sawtooth-shaped humidification membrane is fixed in the outer frame to form a humidification filter element, and the humidification filter element is placed vertically in the sink. Water is sucked from the sink, air enters from the air inlet, passes through the humidification filte...

Embodiment 2

[0068] The humidifying membrane is a non-woven fabric composed of composite fibers and viscose fibers, wherein the core layer of the composite fiber is polyacrylonitrile fiber, the diameter of the core layer is 1 μm, the pore density in the core layer is 500ppi, the pore diameter is 100nm, and the skin layer is Nylon, the thickness of the cortex is 2μm, the pore density in the cortex is 500ppi, and the pore diameter is 100nm. Based on the total mass of the fibers constituting the humidification membrane, the content of composite fibers is 40%, and the content of viscose fibers is 60%.

[0069] The shape, tooth height, tooth density and placement position of the humidifying membrane in this embodiment are the same as those in Embodiment 1.

Embodiment 3

[0071] The humidifying membrane is a non-woven fabric composed of composite fibers and viscose fibers, wherein the core layer of the composite fiber is polyacrylonitrile fiber, the diameter of the core layer is 2 μm, the pore density in the core layer is 1000ppi, the pore diameter is 100nm, and the skin layer is Nylon, the thickness of the cortex is 2 μm, the pore density in the cortex is 1000ppi, and the pore diameter is 100nm. Based on the total mass of the fibers constituting the humidification membrane, the content of composite fibers is 50%, and the content of viscose fibers is 50%.

[0072] The shape, tooth height, tooth density and placement position of the humidifying membrane in this embodiment are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Pore density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com