A cooled infrared thermal imager

An infrared thermal imager and cooling technology, which is applied in the direction of instruments, scientific instruments, optical radiation measurement, etc., can solve the problems of large distance, large detector volume and poor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

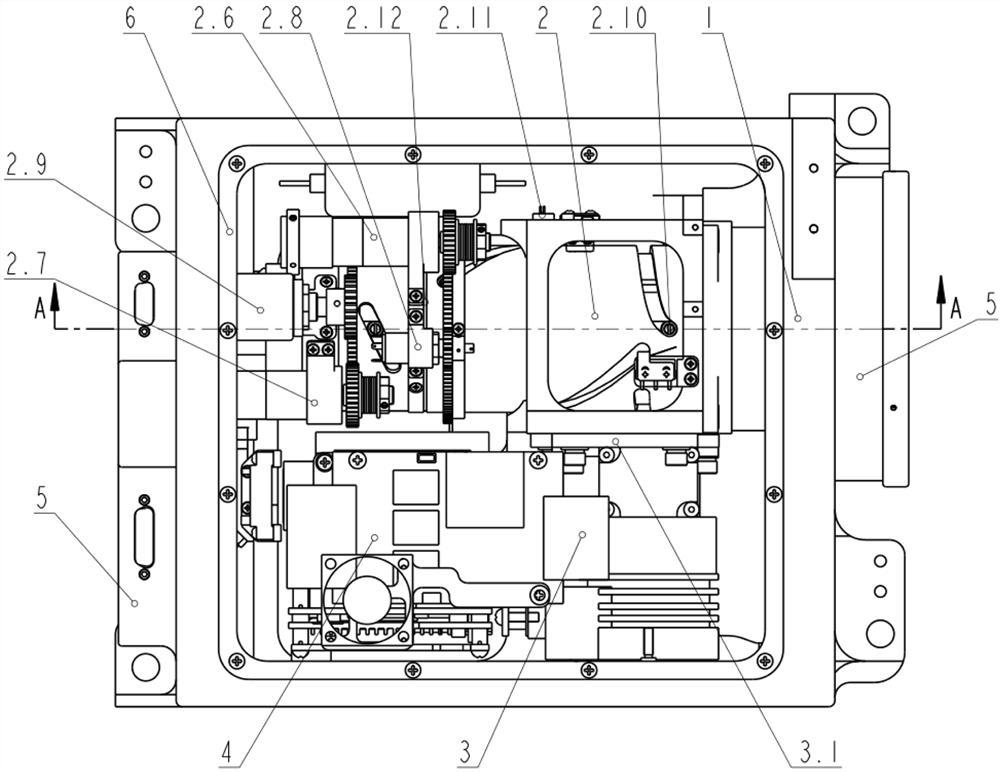

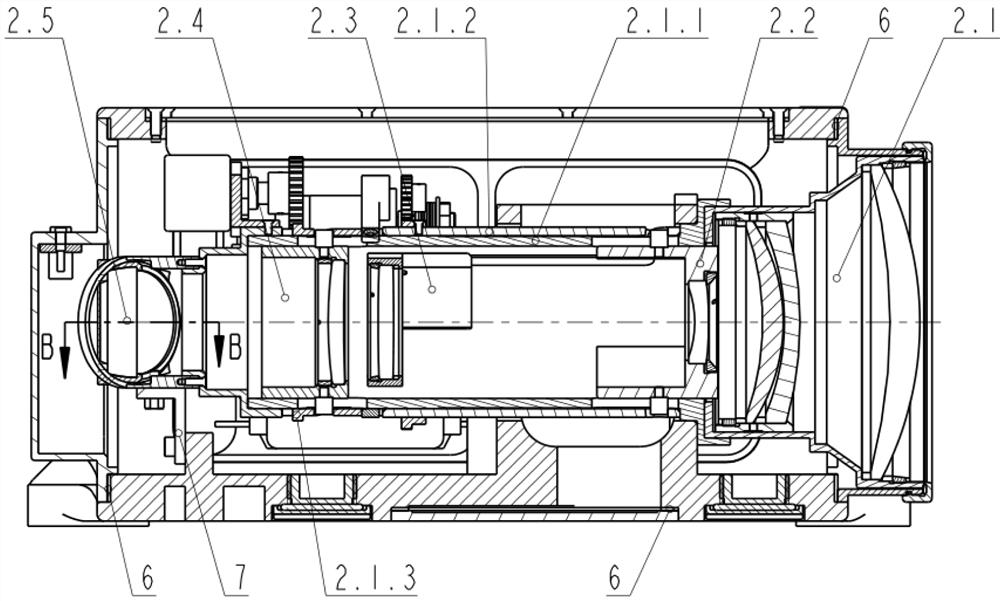

[0024] refer to figure 1 , figure 2 As shown, the cooling type thermal imager based on frame integration design disclosed by the present invention includes a main frame 1, a continuous zoom infrared lens 2, a cooling detector assembly 3, a circuit board group 4, a cover plate 5 and a conductive lining Pad 6; the continuous zoom infrared lens 2 is fixed on the main frame 1 through the flange, and the cooling detector assembly 3 is fixed on the main frame 1 through the detector trimming plate 3.1. The continuous zoom infrared lens 2 and the cooling detector assembly 3 are directly fixed on the main frame 1. Under various harsh environmental test conditions, only a small part of the main frame 1 needs to be strengthened to effectively improve the overall strength of the thermal imager. , to ensure optical axis consistency and parfocality during continuous zooming.

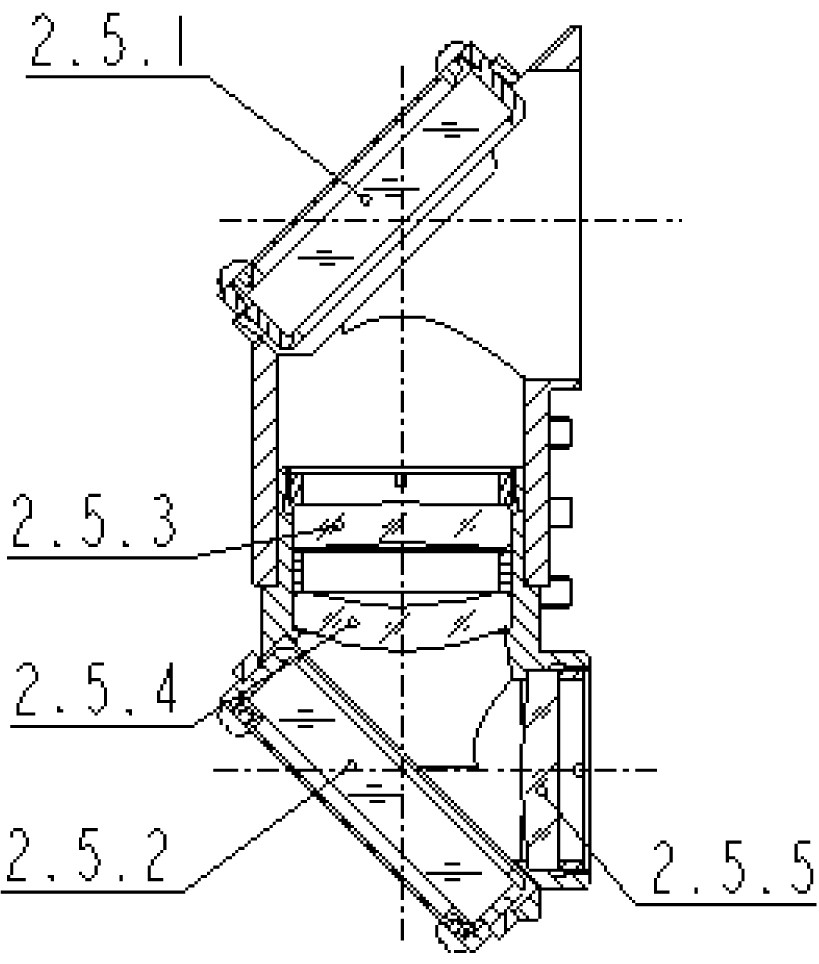

[0025] Described continuous zoom infrared lens 2 is made up of main objective lens group 2.1, zoom group 2.2, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cylindricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com