Method and device for actual torque detection after bolted connection of railway vehicles

An actual torque, rail vehicle technology, applied in measuring devices, measuring torque/torsional force during tightening, instruments, etc., can solve the problems of over-tightening of bolts, low detection accuracy, uncontrollable angle of increase in tightening, etc., to achieve reliable detection and detection. High-speed and effective, realizing the effect of batch inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

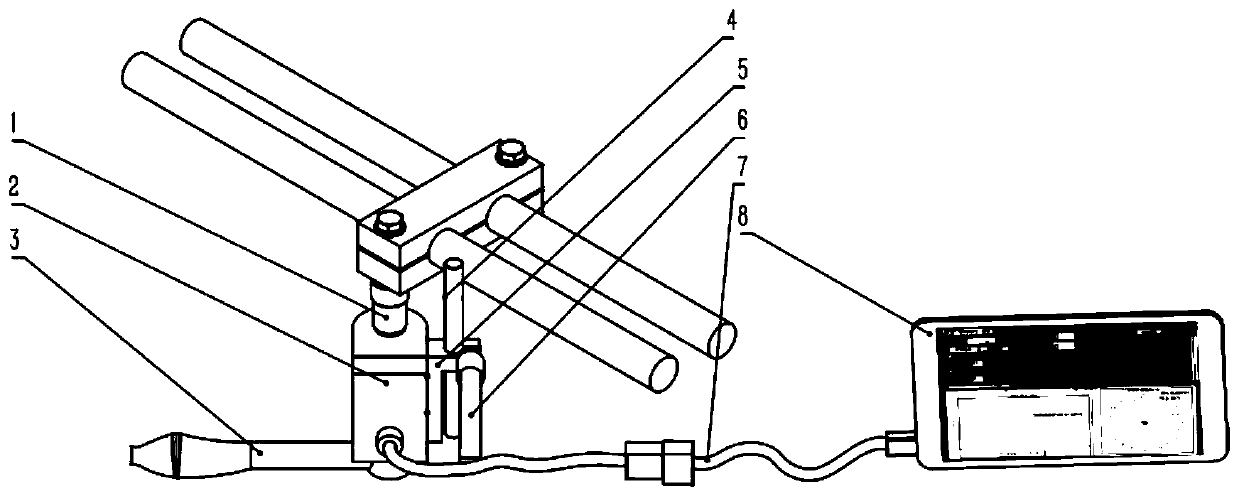

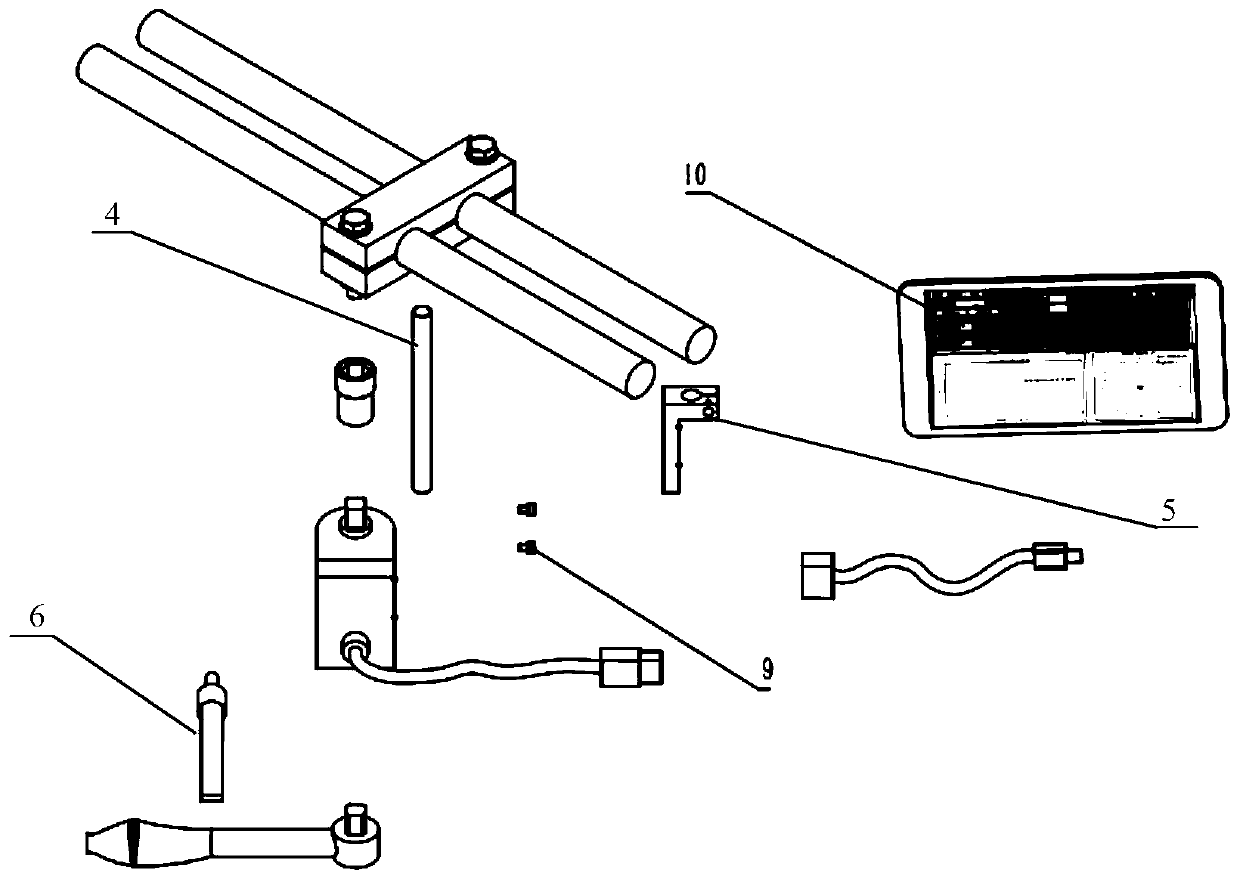

[0029] The invention detects the actual torque of the bolts by means of an increasing screw method. In one embodiment, the present invention provides a method for detecting the actual torque after the rail vehicle is bolted, the method comprising the following steps:

[0030] Tighten the bolts to be tested after connection;

[0031] Detect the angular displacement value and torque value during the tightening process;

[0032] Real-time display, monitor and record the detected angular displacement value and torque value, and set the maximum screw increasing angle in advance, when the detected angular displacement value reaches the maximum screw increasing angle, it will automatically alarm and recor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com