Atomization device and atomization method

An atomization and nebulizer technology, which is used in measurement devices, sampling, instruments, etc., can solve the problems of nebulizer blockage, blockage, atomization efficiency, and stability reduction, to ensure measurement accuracy, reduce blockage, The effect of eliminating precipitation and impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

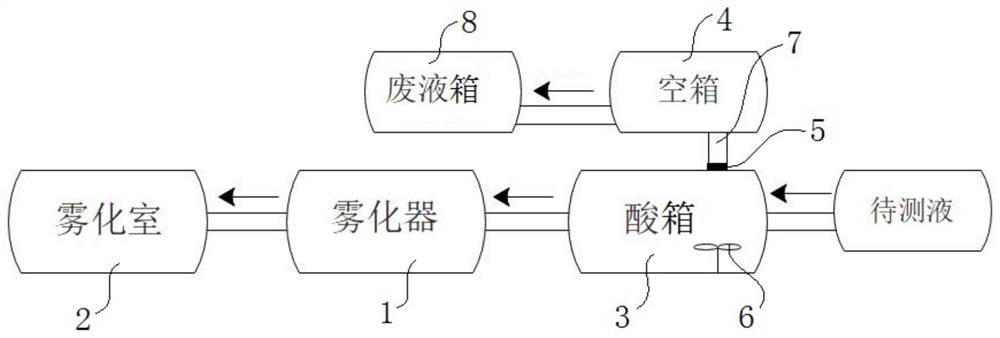

[0031] Such as figure 1 Shown is an embodiment of the atomization device of the present invention, comprising an atomizer 1 and an atomization chamber 2 connected to the output end of the atomizer 1, and is characterized in that the input end of the atomizer 1 is connected with a The acid box 3 of the acid solution, the acid box 3 is provided with an inlet for allowing the liquid to be tested to flow in; the acid box 3 is connected with an empty box 4, and the connection between the acid box 3 and the empty box 4 is provided with An ion exchange membrane 5 that allows the metal ions to be measured to pass through.

[0032] When this embodiment is implemented, the metal ion precipitation in the liquid to be tested reacts with the acid solution to dissolve it in the solution, eliminates the precipitation and impurities in the liquid to be tested, and reduces the clogging of the atomizer 1; and the ion exchange membrane 5 hinders The metal ions enter the empty box 4, thereby eff...

Embodiment 2

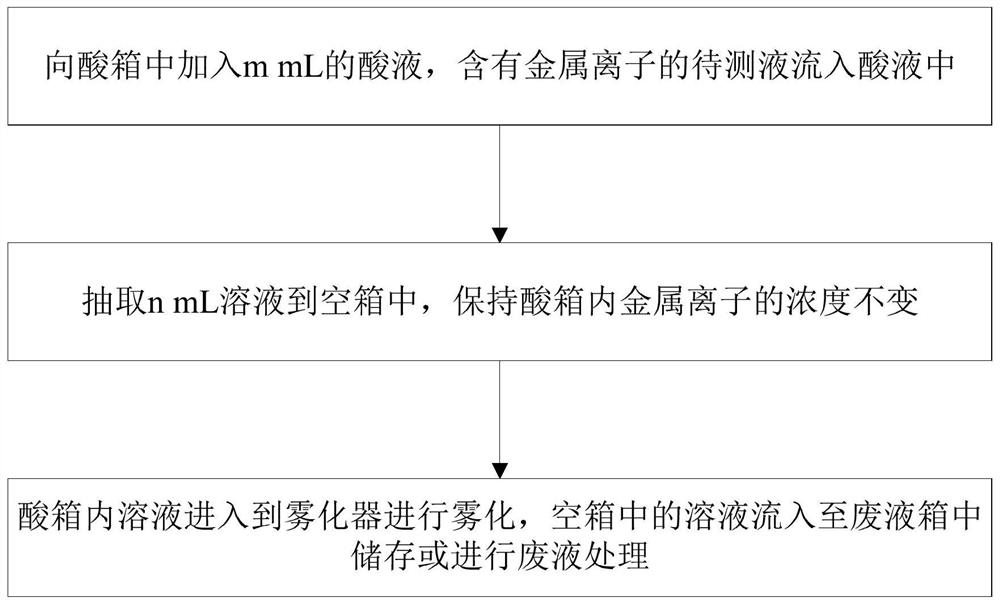

[0039] Such as figure 2 Shown is an embodiment of the atomization method of the present invention comprising the following steps:

[0040] S10. Adding mm mL of acid solution to the acid tank 3, the solution to be tested containing metal ions flows into the acid solution, and the metal ion precipitation reacts with the acid solution to release metal ions;

[0041] S20. After the reaction in step S10 ends, extract n mL of solution into the empty box 4, and keep the concentration of metal ions in the acid box 3 constant;

[0042] S30. After being processed in step S20, the solution in the acid tank 3 enters the atomizer 1 for atomization, and the solution in the empty tank 4 flows into the waste liquid tank 8 for storage or waste liquid treatment.

[0043] In step S10, the pH of the liquid to be tested is >7, and the pH of the acid solution is ≤4. Under this condition, a large amount of metal ions in the liquid to be tested are converted into metal hydroxide precipitates, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com