Portable vibration noise correction and compensation method and a device suitable for atomic interference gravimeter

A technology of atomic interference and vibration noise, which can be used in measurement devices, instruments, scientific instruments, etc., can solve problems such as difficult real-time processing and difficult to meet, and achieve the effect of improving measurement sensitivity and high measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

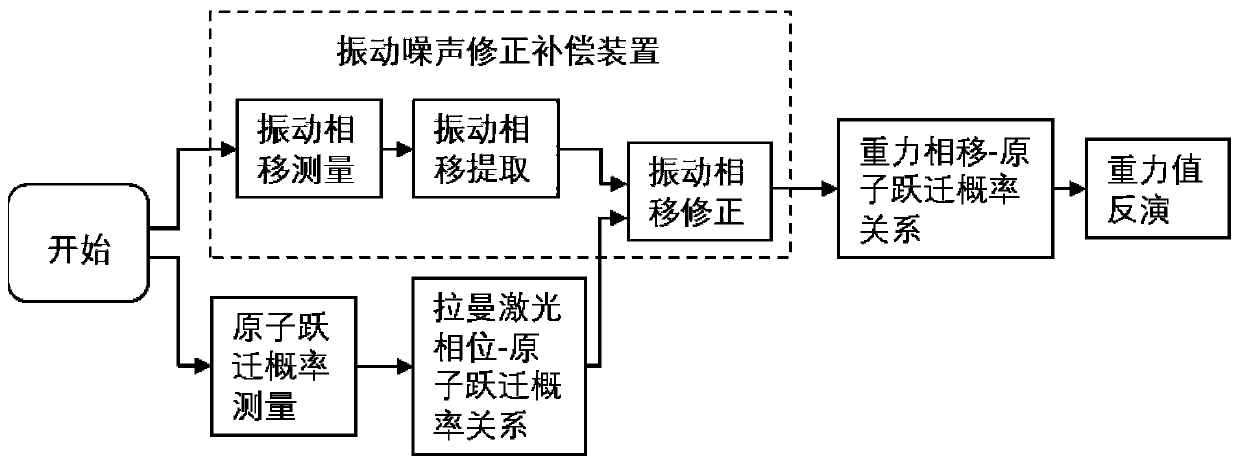

[0044] like figure 1 Shown, a kind of portable vibration noise correction compensation method applicable to atomic interference gravimeter of the present invention, it comprises:

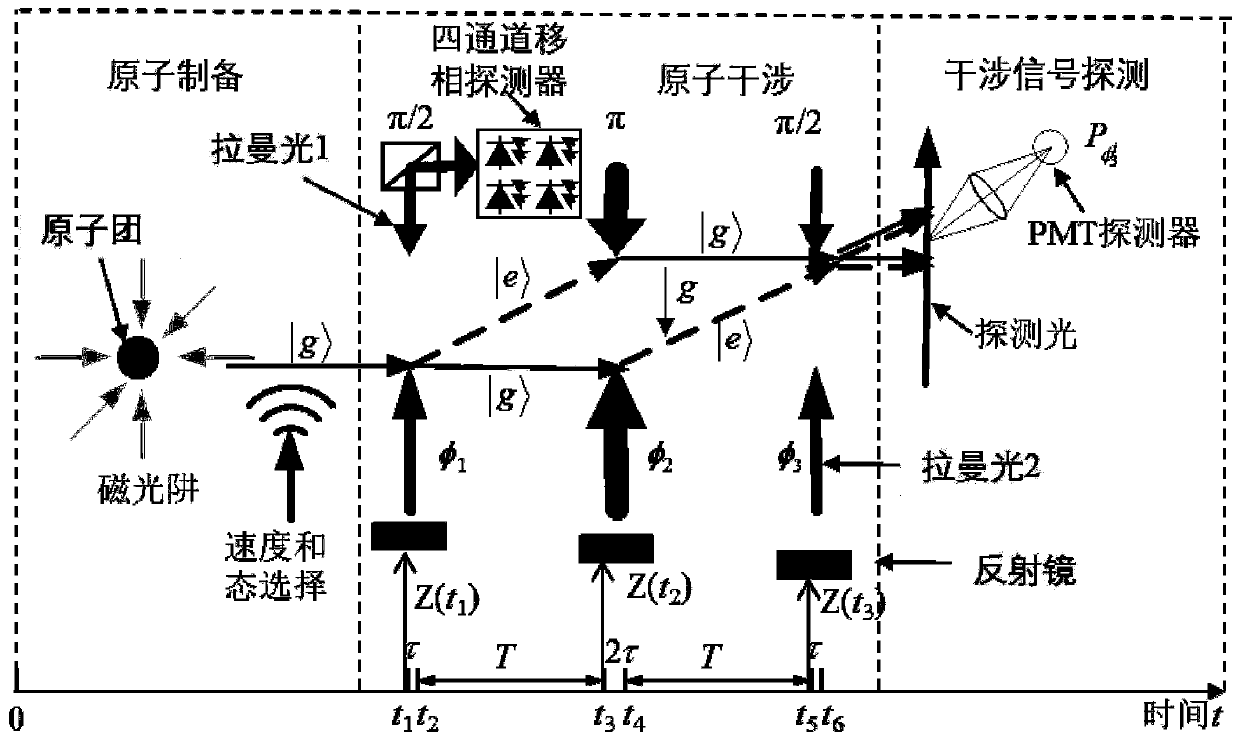

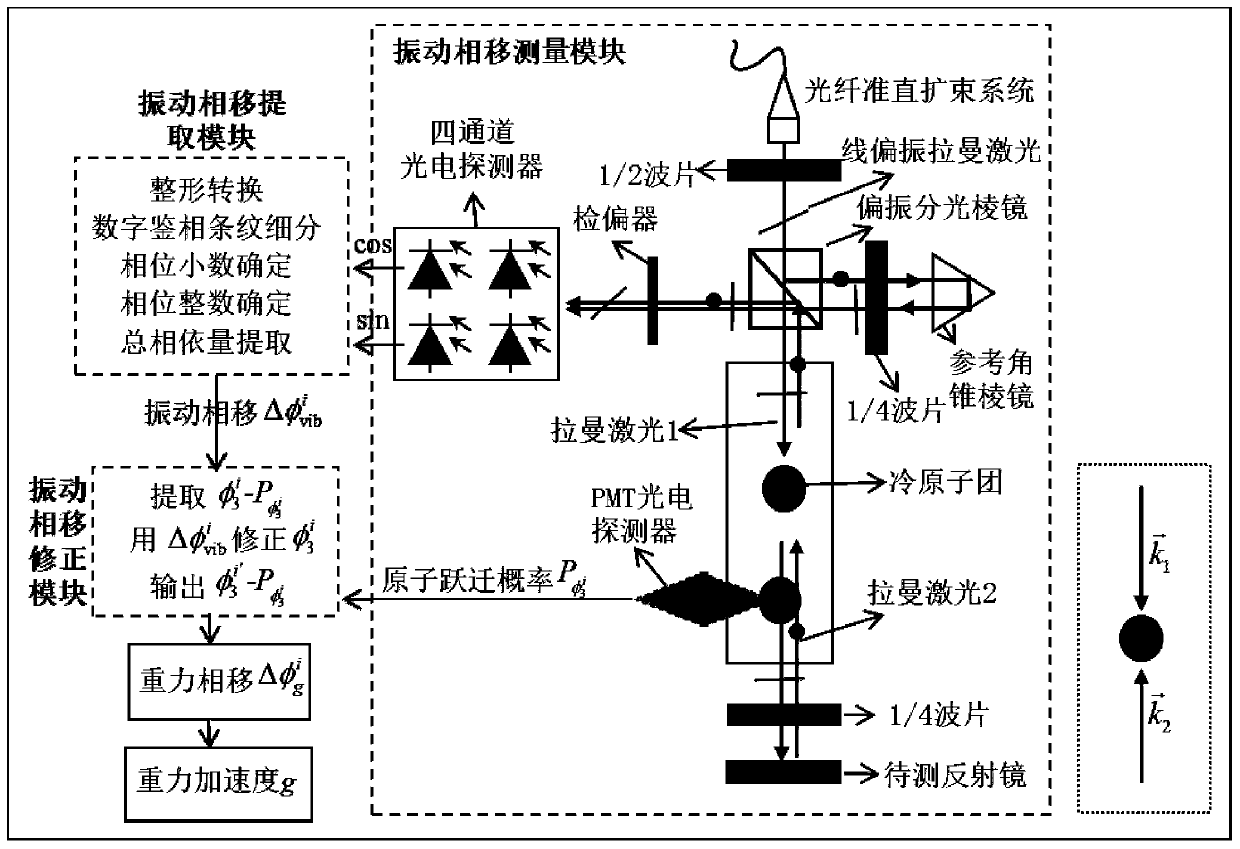

[0045] Step S1, vibration phase shift measurement: monitor the phase shift of the interference fringes of the Michelson-type homodyne laser interferometer caused by the vibration of the mirror through a four-channel phase-shift detector; The four-channel phase-shift detector synchronously collects the phase shift of laser interference fringes caused by mirror vibration during the entire interferometry period.

[0046] Step S2, vibration phase shift extraction: through data processing processes such as shaping conversion, digital phase detection fringe subdivision, and linear superposition, extract the total phase shift caused by the vibration of the mirror ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com