FC optical fibre splice tightening tool

A fiber optic connector and tool technology, applied in the field of fiber optic connection, can solve the problems of laborious installation, manpower, and time-consuming installation, and achieve the effect of avoiding damage and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solutions and advantages of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Obviously, the described embodiments are only part of the embodiments of the present invention, and Not all examples.

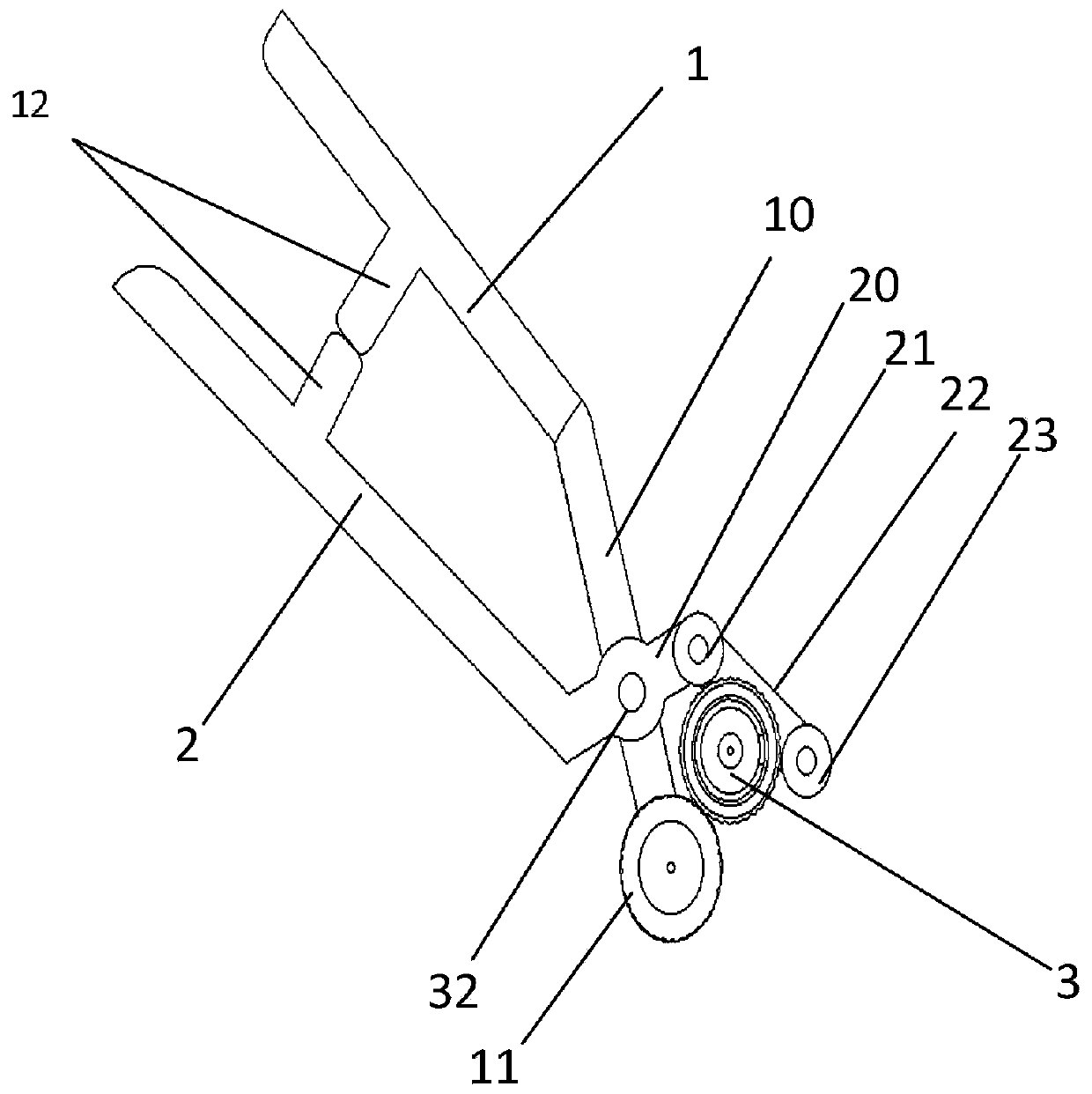

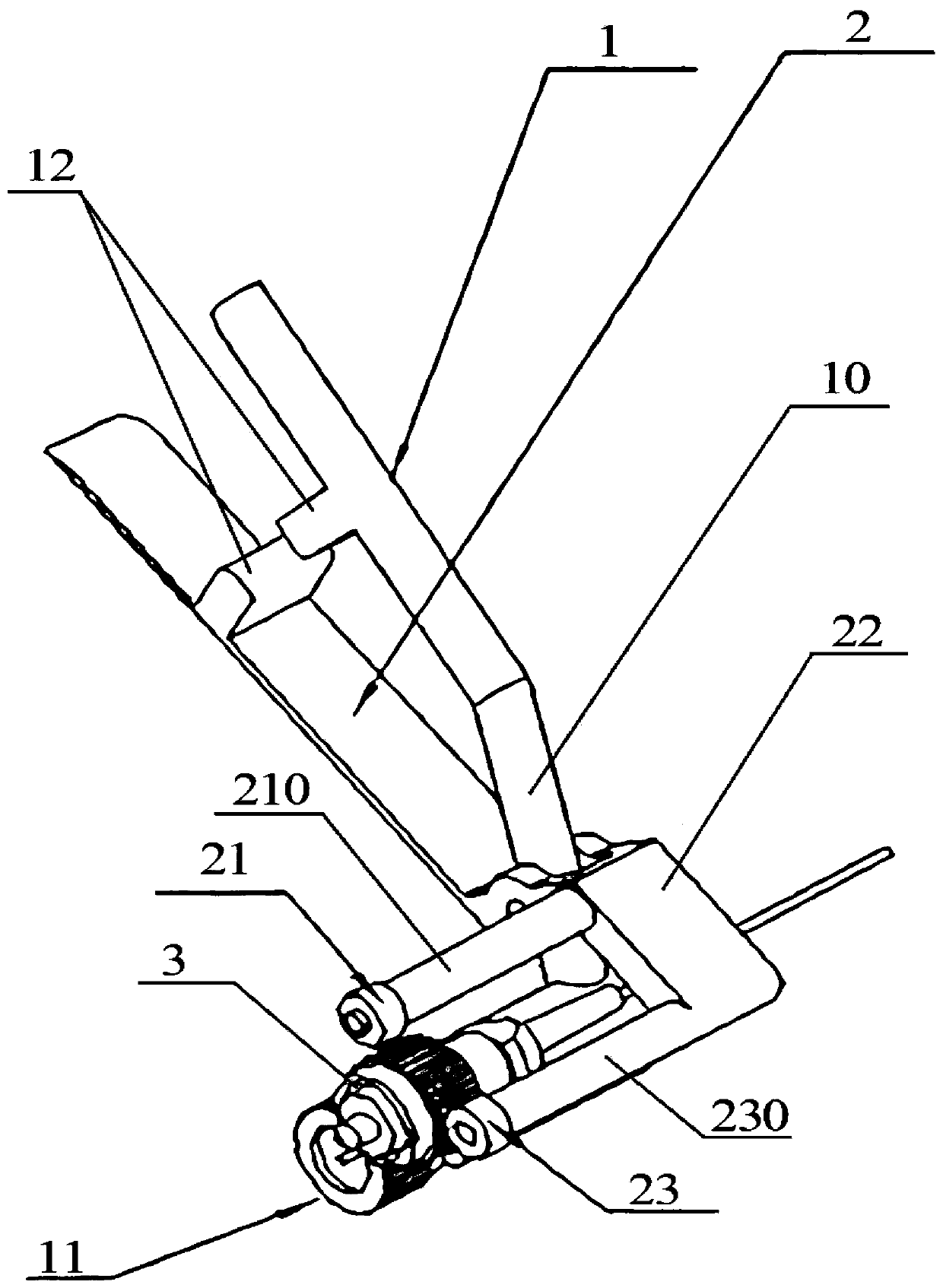

[0022] Reference as figure 1 and figure 2 As shown, a FC optical fiber connector tightening tool, the tightening tool at least includes a motor, a motor handle 1 and a gear handle 2; the end of the motor handle is provided with a first extension section 10 at an offset angle α, and the end of the gear handle The second extension section 20 is provided with an offset angle β; the first extension section 10 and the second extension section 20 are cross-hinged through the rotating shaft 32, and the end of the first extension section 10 is provided with a cylindrical groove to one side, so The mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com