CNC (computer numerical control) machine tool clamp

A technology of CNC machine tools and fixtures, applied in the direction of clamping, clamping devices, manufacturing tools, etc., can solve the problems of stable clamping of plates with single-sided or multi-sided hypotenuses, and achieve the extension of the force arm and improve The effect of stable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

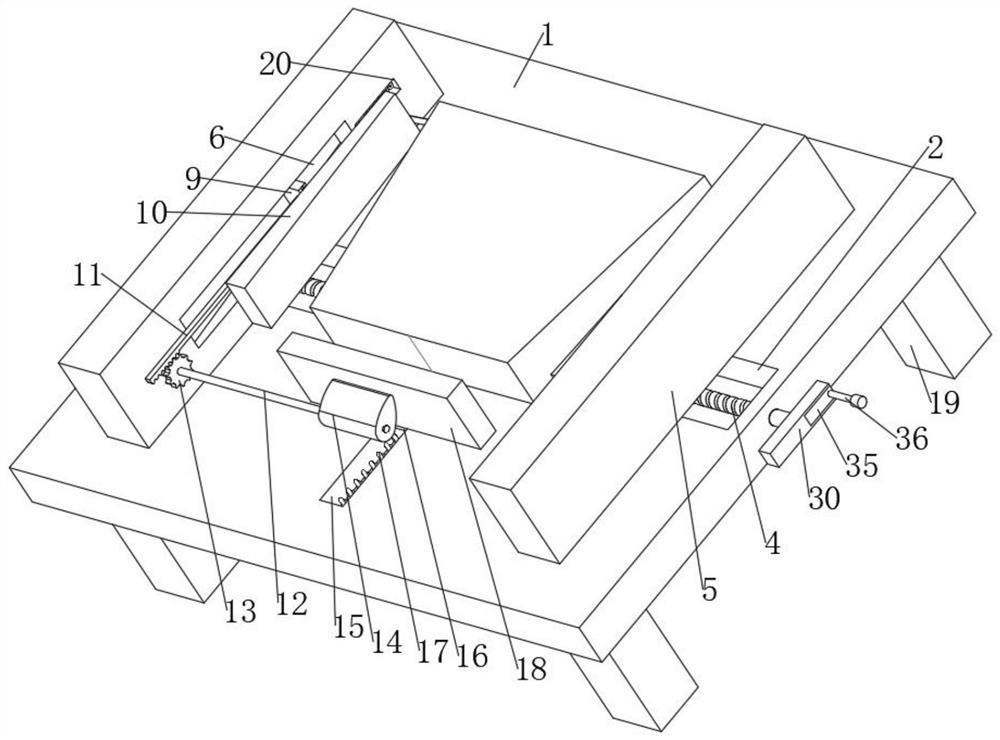

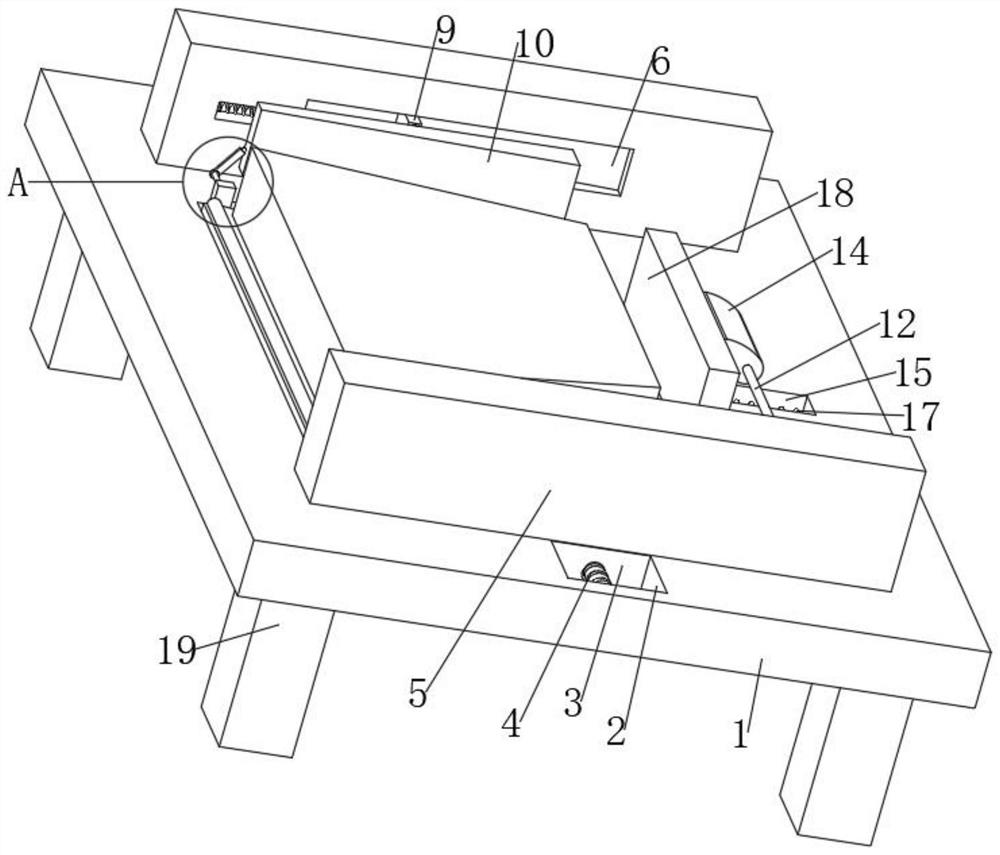

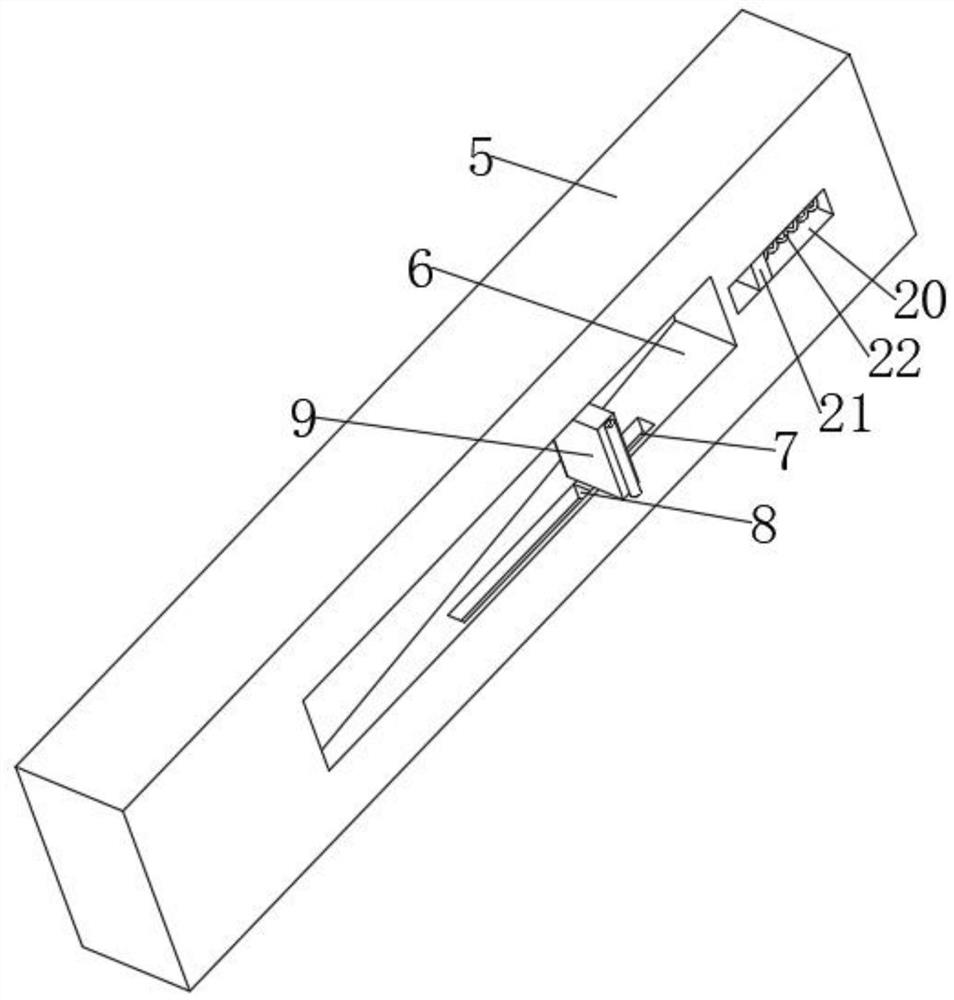

[0028] refer to Figure 1-5 , a CNC numerical control machine tool fixture, including a base plate 1, a plurality of legs 19 are fixed symmetrically by bolts on both sides of the bottom of the base plate 1, a first chute 2 is provided on the top of the base plate 1, and two symmetrical The distributed first slider 3, the same screw 4 is connected to the inner walls on both sides of the first chute 2 through bearing rotation, and a set of reverse threads are provided on the screw 4, the screw 4 and the first slider 3 are threadedly connected, the second The top of a slide block 3 is fixed with a mounting plate 5 by bolts, the inside of the mounting plate 5 is provided with a positioning groove 6, the cross section of the positioning groove 6 is set as a right-angled trapezoid, and the inner wall of the bottom of the positioning groove 6 is provided with a second chute 7, the second chute 7 The inner slide is connected with a second slider 8, the top of the second slider 8 is fi...

Embodiment 2

[0037] refer to figure 1 and Image 6 , a kind of CNC numerical control machine tool fixture, screw rod 4 side is fixed with handle 30 by bolt, and handle 30 outer side is provided with placement groove 31, is provided with extension mechanism in placement groove 31, extension mechanism is connected with extension rod 35, extension rod 35 The outer side is fixed with a handle 36 by a bolt, and the handle 36 can be held, and the extension rod 35 can be pulled out from the placement groove 31, so that the original length of the handle 30 can be extended, and the active force arm can be extended, so that the screw rod can be extended. 4 When rotating, the effect of labor saving can be achieved.

[0038] Further, the extension mechanism includes a limit spring 34, a limit groove 32 is opened on the side wall of the placement groove 31, and a limit block 33 is slidably connected in the limit groove 32, and the limit spring 34 is fixed to the limit block 33 and the limit block by b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com