Overhaul plan TIER4 evaluation technology based on shutdown overhaul of refining device

A maintenance planning and refining technology, which is applied in the field of device shutdown and maintenance, can solve the problems of insufficient effectiveness and precision of maintenance items, failure to really effectively improve system reliability and efficiency, and wrong repairs, and achieve the effect of effective optimization and evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

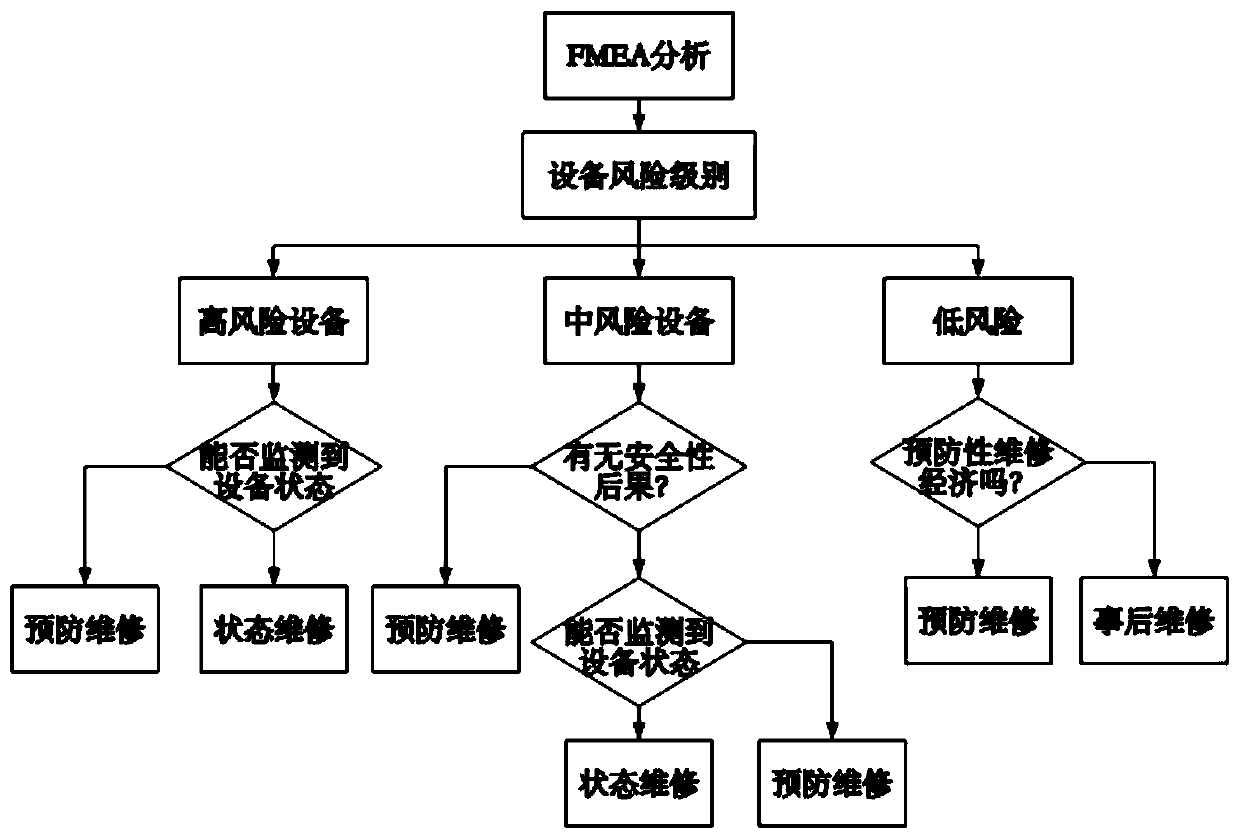

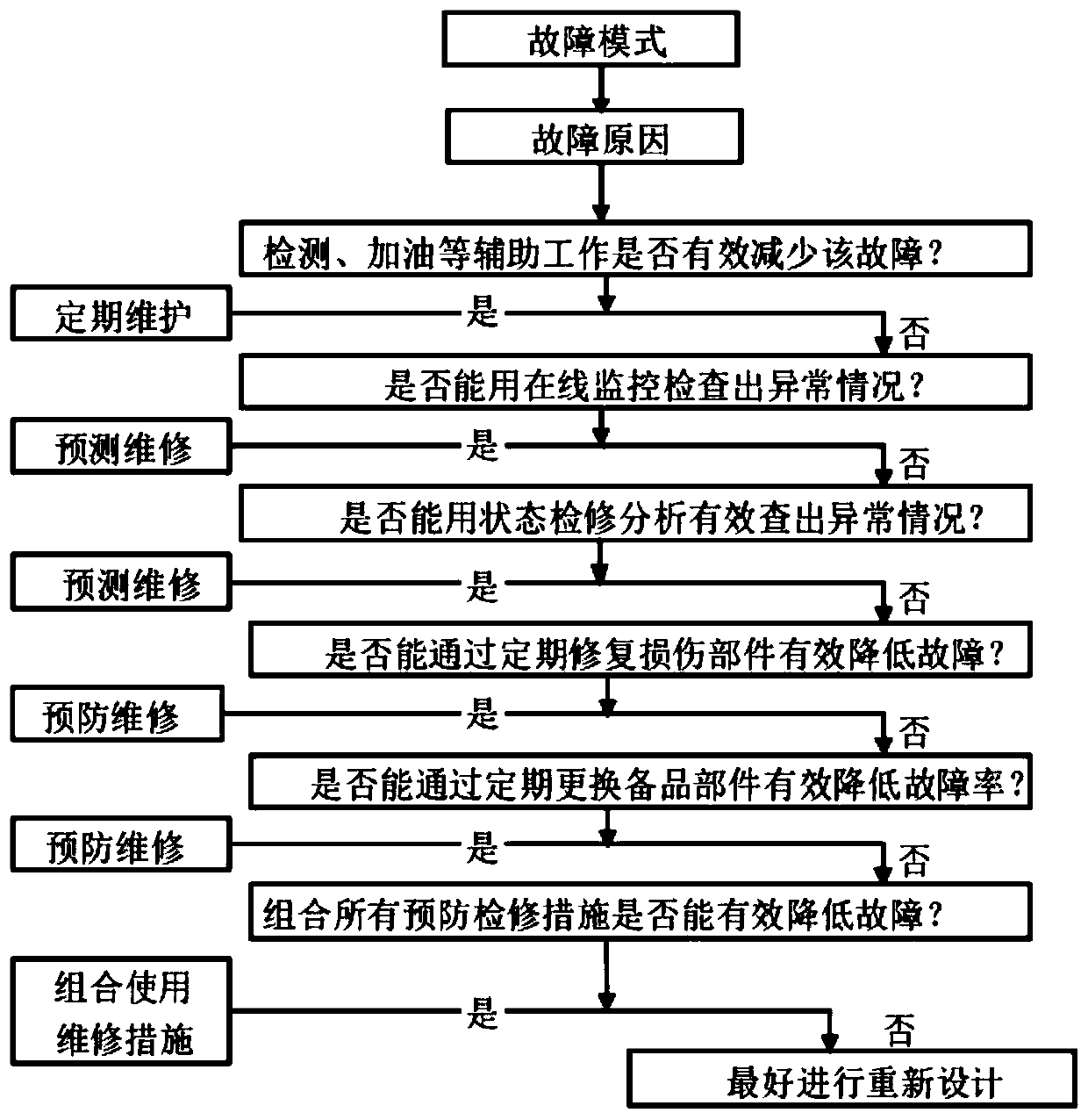

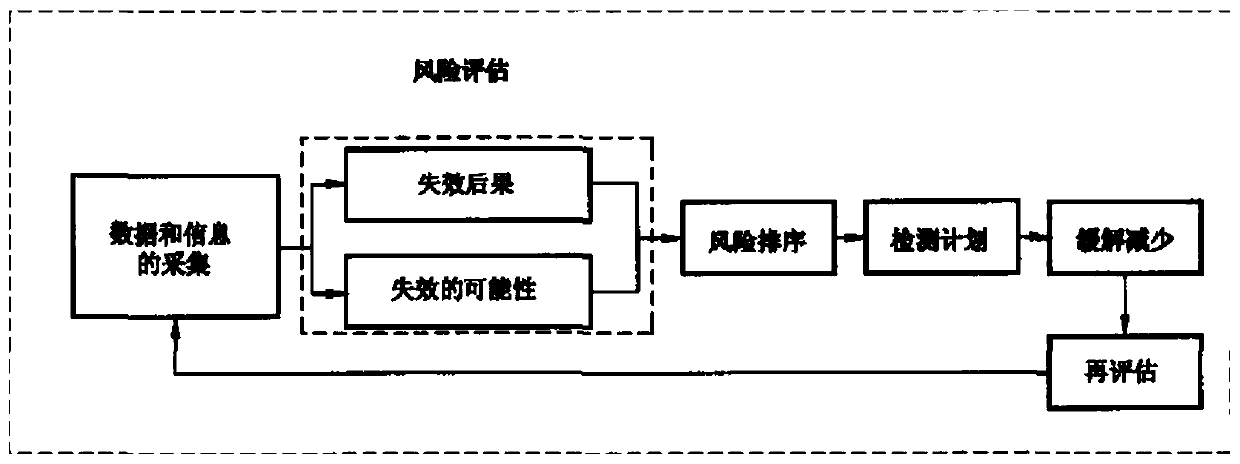

[0036] Embodiment: A kind of maintenance plan TIER4 evaluation technology based on refinery plant shutdown overhaul, including (1) Trend (equipment status detection trend), (2) Integrity (process integrity), (3) Experience (expert experience), ( 4) Reliability (based on reliability management theory), (5) Risk Technology (risk assessment technology application results), (6) Regular (regular inspection regulations and implementation standards), (7) Remains (legacy issues);

[0037] The (1) Trend (equipment status detection trend): using advanced equipment detection technologies such as heating furnace evaluation, unit status monitoring, leakage detection, infrared monitoring, corrosion monitoring, heat exchanger thermal efficiency evaluation, etc. Performance parameters and equipment characteristic data, after processing and analysis, obtain information reflecting equipment status and fault symptoms, grasp the operation status of on-site equipment, and realize equipment status e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com